Axial-flow inverted umbrella aerator

An aerator and axial flow technology, applied in the field of axial flow inverted umbrella aerator, can solve the problem that the oxygenation process is limited to the surface of the water body, and achieve the effect of improving the use efficiency and dissolved oxygen rate, and changing the lifting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

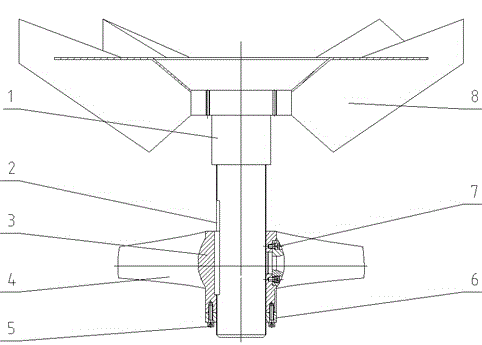

[0020] Such as figure 1 As shown, the axial-flow inverted umbrella aerator of the present invention includes a motor drive device, an output shaft, and an aeration impeller; the drive device is connected to the aeration impeller through the output shaft, and drives the aeration impeller to rotate.

[0021] The aeration impeller includes an impeller shaft 1 , a key 2 , an axial flow vane hub 3 , an axial flow vane 4 , a positioning screw 5 , a limit nut 6 , an adjustment screw 7 and an aeration vane 8 . The aeration blade 8 , the hub 3 of the axial flow blade and the limit nut 6 are arranged coaxially on the impeller shaft 1 sequentially from top to bottom. The hub 3 of the axial flow blade is keyed to the impeller shaft 1 through the key 2; the limit nut 6 is screwed to the impeller shaft 1. The axial blades 4 are arranged on the outer wall of the axial blade hub 3 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com