A kind of preparation method of water-soluble polymer surface graft modification machine-made sand

A technology of surface graft modification and water-soluble polymer, which is applied in the field of preparation of water-soluble polymer modified machine-made sand, can solve the problems of increasing the flow resistance of the mixture, increasing the water demand, increasing the cost, etc., and achieving Improve the flexural strength, improve the ease of use, and reduce the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

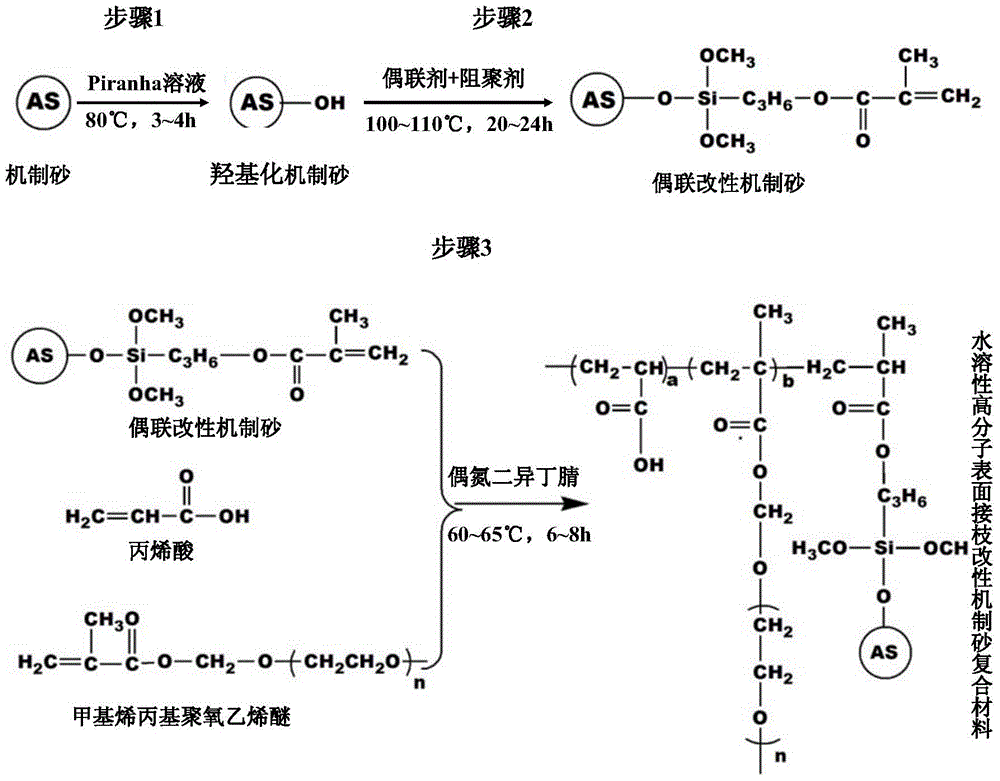

[0027] In this example, the water-soluble surface graft modified machine-made sand is prepared according to the following steps:

[0028] Step 1: Hydroxylation treatment:

[0029] First, in an ice-water bath, slowly add 10 mL of hydrogen peroxide with a mass concentration of 30% into 50 mL of concentrated sulfuric acid with a mass concentration of 98%, and stir while adding to obtain a Piranha solution;

[0030] Then the Piranha solution was added to a beaker equipped with 30 g of machine-made sand, and reacted slightly at 80° C. in a water bath for 4 h to obtain reaction solution A. The Piranha solution in the reaction solution A was removed by centrifugation, and the resulting solid product was washed with deionized water for more times, and finally vacuum-dried to obtain hydroxylated machine-made sand;

[0031] Step 2: Coupling agent modification

[0032] Add 10 g of the hydroxylated machine-made sand obtained in step 1 and coupling agent KH-5707 mL into toluene as a solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com