Special roller-pressing treatment system for barks of eucommia ulmoide

A processing system and rolling technology, which is applied in the field of eucommia bark special rolling processing system, can solve the problems of high production cost, serious environmental pollution, low purity of eucommia gum, etc., and achieve the goal of maintaining structure and polymerization degree and ensuring physical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

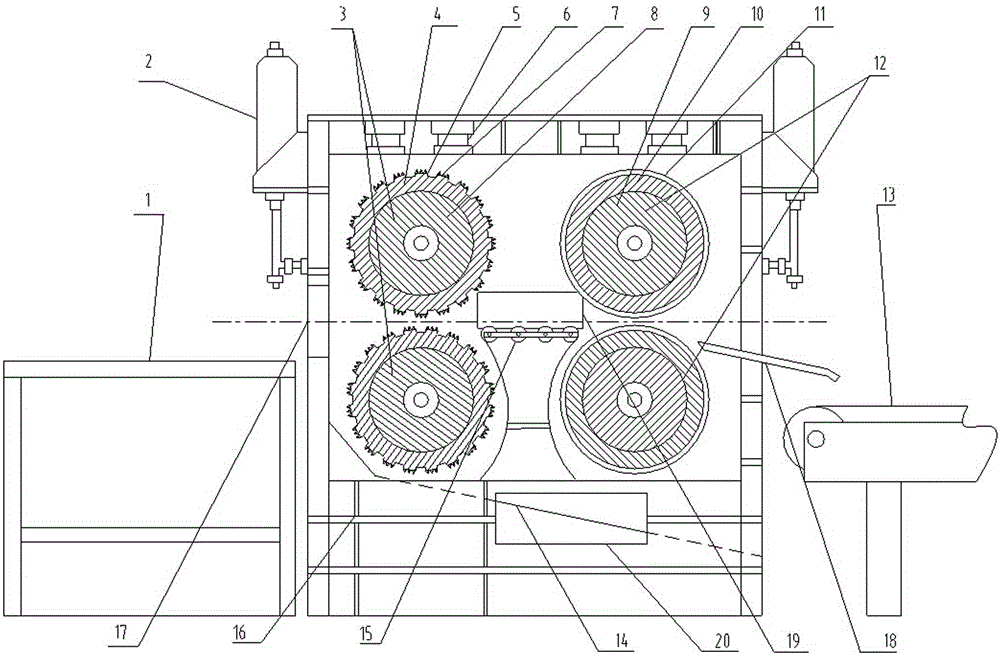

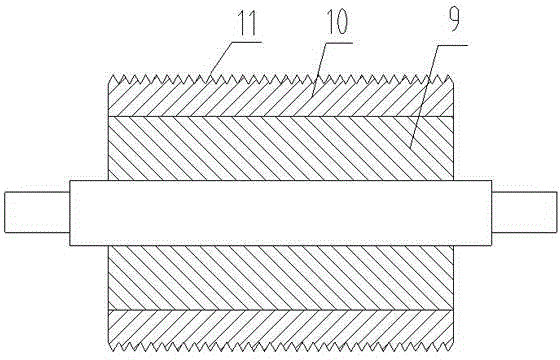

[0018] As shown in the figure, a special rolling processing system for Eucommia bark includes a frame 16, and two pairs of pressure rollers are horizontally spaced on the frame 16, which are respectively the first pair of pressure rollers 3 and the second pair of pressure rollers 12.

[0019] The two pairs of pressure rollers are arranged in parallel up and down, and the pressure rollers located above are movable rollers, and each movable roller is connected with two hydraulic cylinders 6, and the two movable rollers are respectively driven by their respective hydraulic systems. The cylinder 6 is driven to realize the movement of the movable roller into and out of the roller. Accumulators 2 are respectively provided in the two hydraulic systems, and the accumulators 2 convert the energy in the system into compression energy or po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com