Hard wire steel wire rod

A steel wire rod and hard wire technology, applied in the field of steel forming, can solve the problems of substandard drawing performance and low degree of sorbitization, so as to overcome the surface decarburization of castings, high degree of sorbitization and uniform cooling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The method for preparing the hard wire steel wire rod in this embodiment comprises the following steps:

[0030] 1), smelting: the molten steel melt is smelted by converter + LF refining;

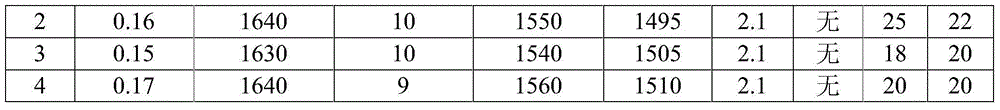

[0031] In this embodiment, the smelting process parameters are shown in Table 2, Example 1.

[0032] 2), casting: the molten steel of continuous casting step 1) is cast slab;

[0033] In the present embodiment: continuous casting process parameter and casting quality are as shown in table 2 embodiment 1;

[0034] 3), heating: the heating in this embodiment is carried out in three sections, and the heating process parameters of each section are as shown in Table 3, Example 1.

[0035] 4), rolling: rolling the slab heated in step 3) in the order of rough rolling→intermediate rolling→pre-finish rolling→finish rolling. In this embodiment, a total of 28 stands of continuous rolling units are used for rolling, and the first 18 stands Horizontal-vertical alternate arrangement, every grou...

Embodiment 2

[0039] The method for preparing the hard wire steel wire rod in this embodiment comprises the following steps:

[0040] 1), smelting: the molten steel melt is smelted by converter + LF refining;

[0041] In this embodiment, the smelting process parameters are shown in Table 2, Example 2.

[0042] 2), casting: the molten steel of continuous casting step 1) is cast slab;

[0043] In the present embodiment: continuous casting process parameter and casting quality are as shown in table 2 embodiment 2;

[0044] 3), heating: the heating in this embodiment is carried out in three sections, and the heating process parameters of each section are as shown in Table 3, Example 2.

[0045] 4), rolling: rolling the slab heated in step 4) in the order of rough rolling→intermediate rolling→pre-finish rolling→finish rolling. In this embodiment, a total of 28 stands of continuous rolling units are used for rolling, and the first 18 stands Horizontal-vertical alternate arrangement, every grou...

Embodiment 3

[0049] The method for preparing the hard wire steel wire rod in this embodiment comprises the following steps:

[0050] 1), smelting: the molten steel melt is smelted by converter + LF refining;

[0051] In this embodiment, the smelting process parameters are shown in Table 2, Example 3.

[0052] 2), casting: the molten steel of continuous casting step 1) is cast slab;

[0053] In the present embodiment: continuous casting process parameter and casting quality are as shown in table 2 embodiment 3;

[0054] 3), heating: the heating in this embodiment is carried out in three sections, and the heating process parameters of each section are as shown in Table 3, Example 3.

[0055] 4), rolling: rolling the slab heated in step 4) in the order of rough rolling→intermediate rolling→pre-finish rolling→finish rolling. In this embodiment, a total of 28 stands of continuous rolling units are used for rolling, and the first 18 stands Horizontal-vertical alternate arrangement, every grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com