Fake hemp knitted fabric and production method and application thereof

A production method and technology of knitted fabrics, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of air-deformed yarn with many loops, not having the unique style of natural hemp fiber, and easy to fade, so as to achieve comfortable wearing, Superior cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

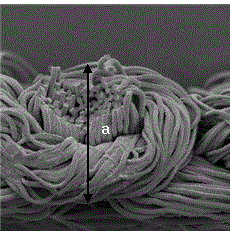

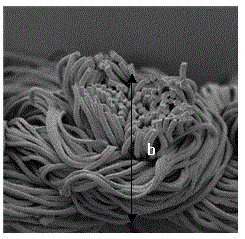

Image

Examples

Embodiment 1

[0041] Using 95D-36f-polyester fused with DTY and 75D-36f-bright polyester FDY for weaving, the organization is ordinary jersey, and knitted gray fabric is woven on a 28G single-jersey machine, and the fusion area of the fusion yarn used is The length is 16mm, and its proportion in the length direction is 56%. The mixed rate of the fused yarn in the obtained knitted gray fabric is 56%. After refining and desizing in the cylinder (scouring agent 0.5g / l), the intermediate setting (190°C treatment for 60 seconds), 9% weight reduction processing, 130°C for 30 minutes, disperse dyeing, 160°C resin finishing (hydrophilic agent 10g / l, pH regulator 1g / l), the weight is 120g / m 2 The properties of knitted fabrics are shown in Table 1.

Embodiment 2

[0043]Using 95D-36f-polyester fused with DTY and 75D-36f-delustered polyester FDY for weaving, the organization is ordinary cotton wool, woven into knitted gray fabric on a 28G double-sided machine, and the length of the fused area of the fused yarn used is 16mm, and its proportion in the length direction is 56%, the blending rate of the fused yarn in the obtained knitted gray fabric is 56%, after scouring and desizing in the cylinder (scouring agent 0.5g / l), the weight reduction rate is 12 % reduction processing, dyeing with disperse dyes at 135 degrees for 30 minutes, resin finishing at 160 degrees (hydrophilic agent 10g / l, pH regulator 1g / l), and the weight is 159g / m 2 The properties of knitted fabrics are shown in Table 1.

Embodiment 3

[0045] Using 63D-72f-polyester fused with DTY for weaving, the organization is ordinary jersey, and knitted gray fabric is woven on a 28G single-jersey machine. The length of the fused area of the fused yarn used is 6mm, and its length direction The proportion above is 62%, and the mixed rate of the fused yarn in the obtained knitted gray fabric is 100%, after scouring and desizing in the cylinder (scouring agent 0.5g / l), intermediate setting (185 degrees for 60s), 130 degrees Dyeing with disperse dyes for 20 minutes, resin finishing at 160°C (hydrophilizing agent 10g / l, pH regulator 1g / l) and air beating processing (treatment at 100°C for 20min), resulting in a grammage of 64g / m 2 The properties of knitted fabrics are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com