Isothermal expansion power system by hydraulic pressure

A power system, isothermal expansion technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of affecting the normal operation of the machine, increasing the cost, reducing the efficiency of the expander system, etc., to improve the output work per unit of working fluid, Improved overall efficiency and high system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

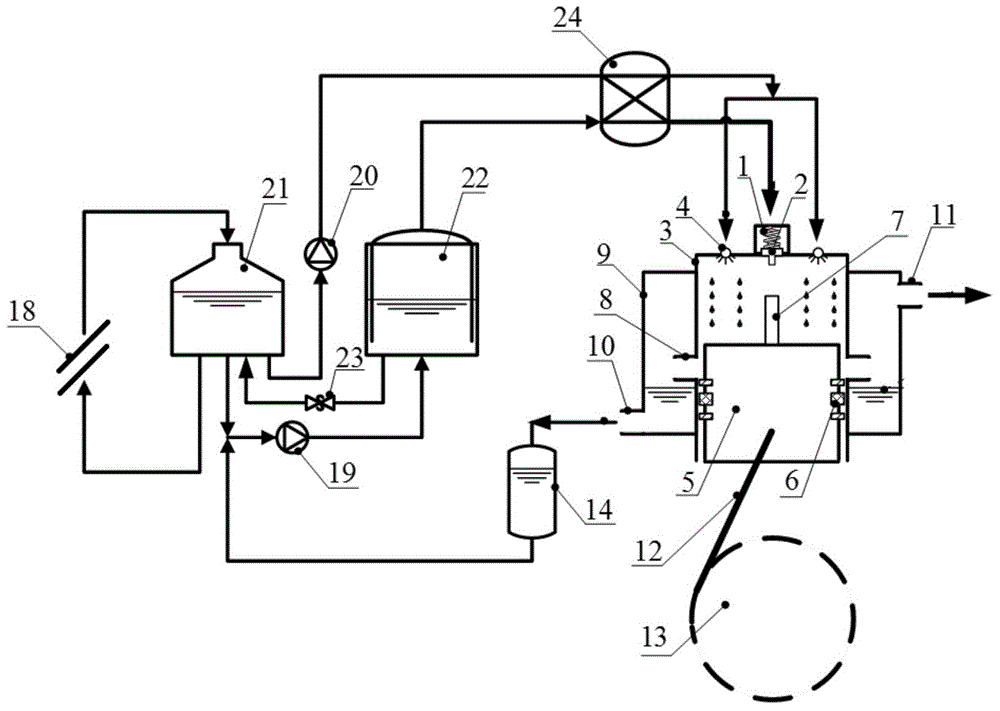

[0036] figure 1 It is a structural schematic diagram of Embodiment 1 of the hydraulic isothermal expansion power system of the present invention. The system includes a piston 5, a cylinder 3, a crank connecting rod mechanism, a high-pressure gas working medium storage tank 22, a heating medium storage tank 21 and a heat exchanger 24. The piston 5 is slidably installed in the cylinder 3, and the crank connecting rod mechanism includes a connecting rod 12 And crank 13, one end of connecting rod 12 is connected with piston 5, and the other end is connected with crank 13, and the top of cylinder 3 is equipped with intake valve 2 and annular injector 4, and the intake port 1 of intake valve 2 is connected with high-pressure gas working fluid storage The tank 22 is in communication, and the annular injector 4 is in communication with the heating medium storage tank 21, so as to atomize the heated heating medium or form foam and inject it into the cylinder 3 at a certain mass flow ra...

Embodiment 2

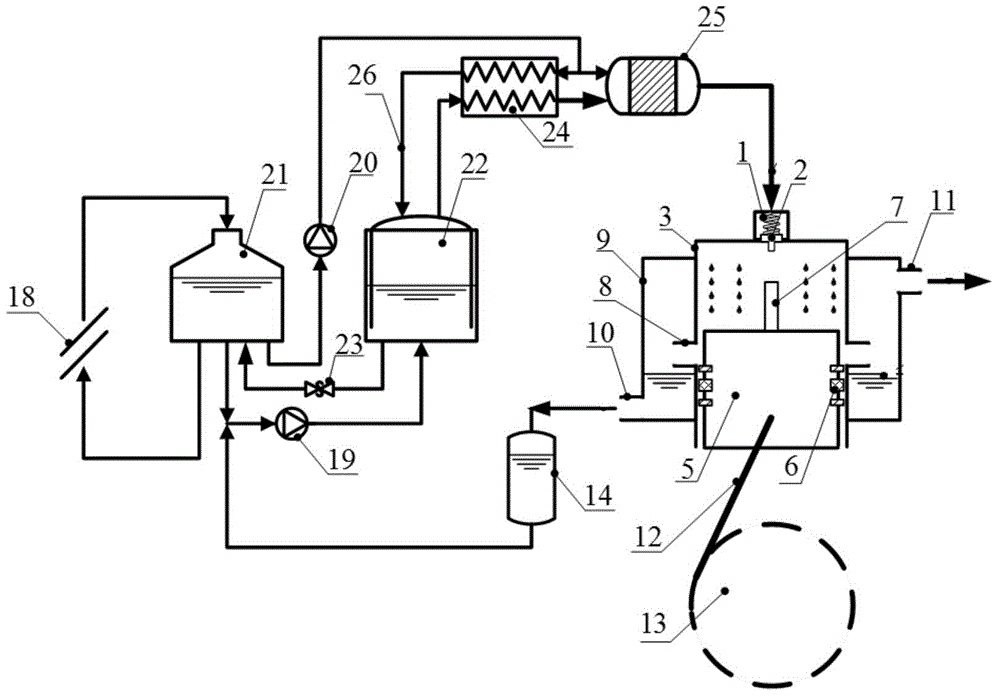

[0039] figure 2 It is a schematic structural diagram of Embodiment 2 of the present invention, and its main structure is the same as that of Embodiment 1. Compared with Embodiment 1, the difference between the heating medium and the gas is that after the heat exchange between the heating medium and the gas through the heat exchanger 24 and before entering the cylinder 3, The two enter a mixer 25, and then the fully mixed gas-liquid two-phase flow is sprayed into the cylinder 3. It is no longer necessary to install an annular injector on the top of cylinder 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com