A kind of multiple cam pump

A cam pump and cam technology, applied in pumps, pump components, rotary piston pumps, etc., can solve problems such as not too many pumps in series, inconvenient system control, maintenance, poor consistency of output characteristics, etc., to achieve consistent fluid characteristics Good performance, compact structure and consistent fluid properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described below based on the drawings.

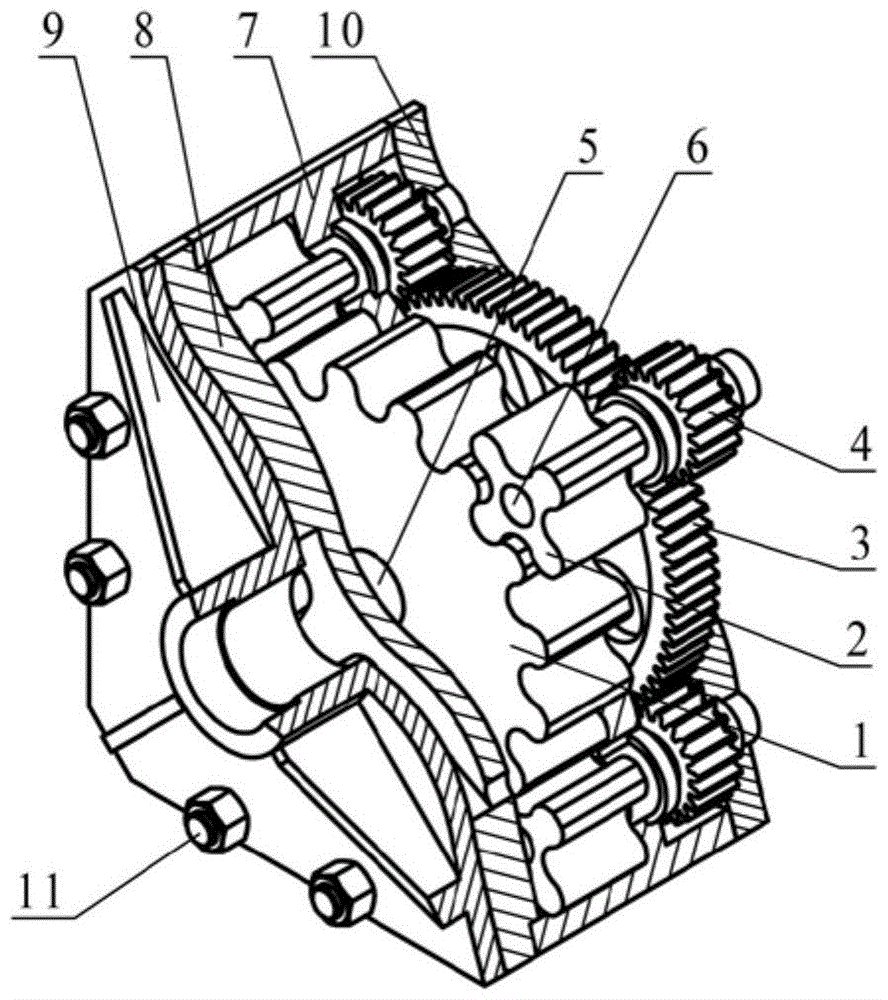

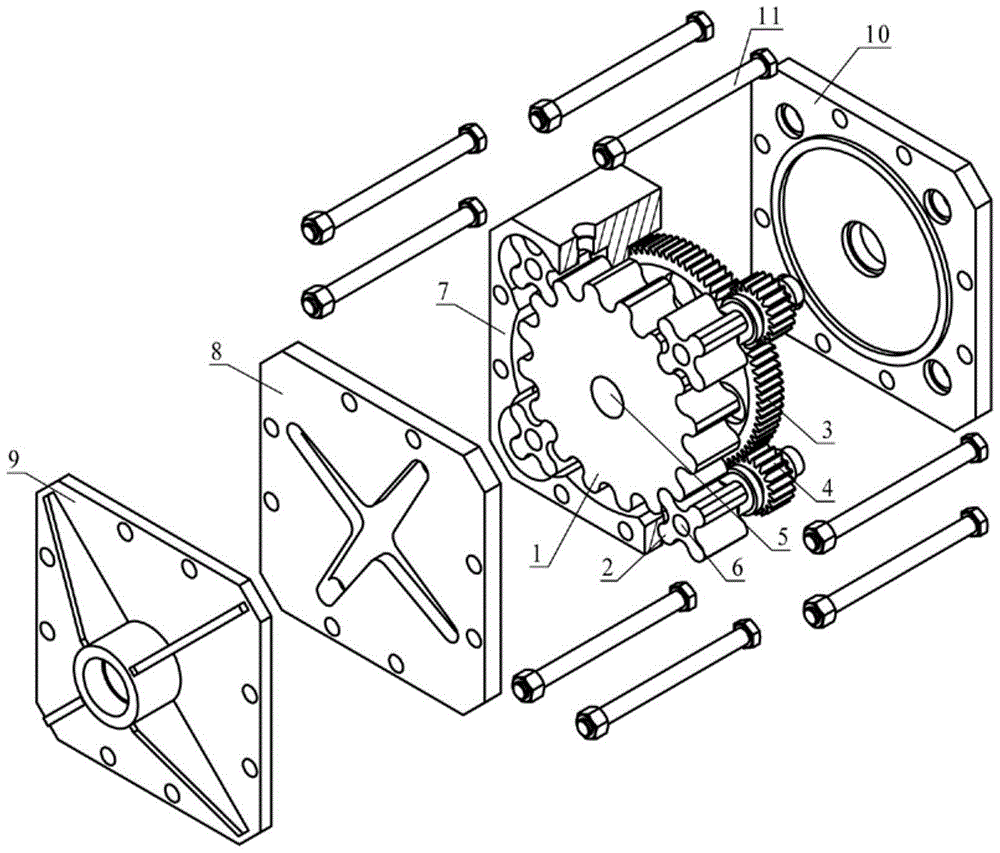

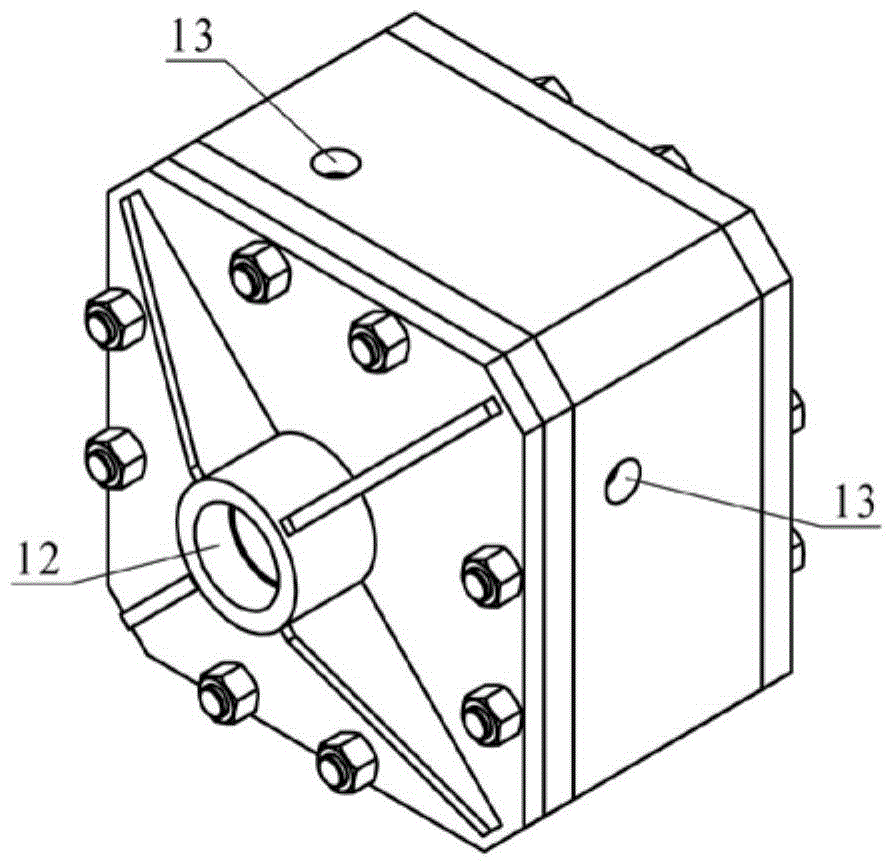

[0021] figure 1 , figure 2 The multiple cam pump shown is composed of driving cam 1, driven cam 2, driving gear 3, driven gear 4, driving shaft 5, driven shaft 6, pump body 7, valve plate 8, front cover 9, rear cover 10. , The connecting bolt 11 is composed, and the driving force is input from the driving shaft 5. Among them, the pump body 7 has two front and rear cavities. The pump body 7 and the valve plate 8 are connected to form a closed cavity for the operation of the cam pump, and the pump body 7 and the rear cover 10 are connected to form a gear transmission cavity; The cam 1 is connected to the driving gear 3 through the driving shaft 5 and runs coaxially. The 4 identical driven cams 2 are respectively connected to the 4 identical driven gears 4 through 4 identical driven shafts 6 , And operate coaxially respectively, the driving shaft 5 and the 4 driven shafts 6 have the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com