Low-noise centrifugal fan impeller for high-speed electric multiple unit cooling system

A cooling system and centrifugal fan technology, applied in engine manufacturing, machine/engine, liquid fuel engine, etc., can solve the problem of high noise in the cooling system, and achieve the effects of high cooling efficiency, reliable operation and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

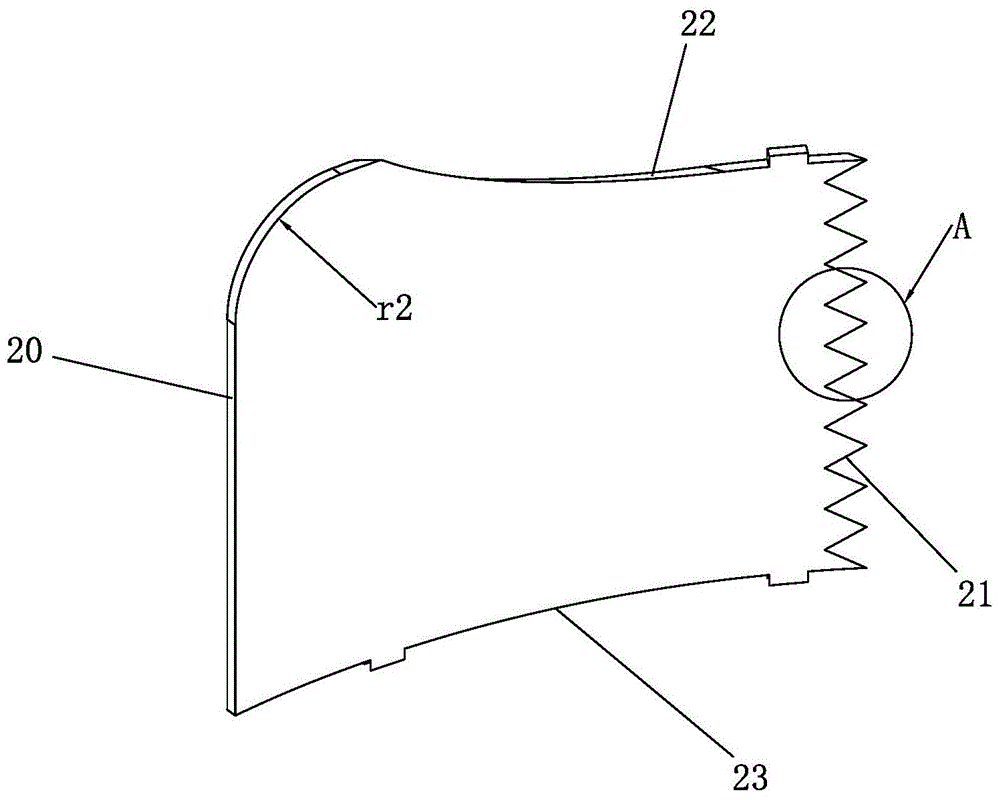

[0019] The reasons for the aerodynamic noise of the centrifugal impeller mainly include the following aspects: (1) the interaction between the unstable flow of the airflow at the inlet of the fan impeller and the impeller; (2) the separation of the airflow in the flow channel on the blade interface to generate vortices, Vortex separation produces vortex shedding noise; (3) the sudden diffusion of airflow at the outlet of the impeller airflow causes the airflow to be sparse and generates noise; (4) the noise generated by the interaction between the high-speed airflow and the casing.

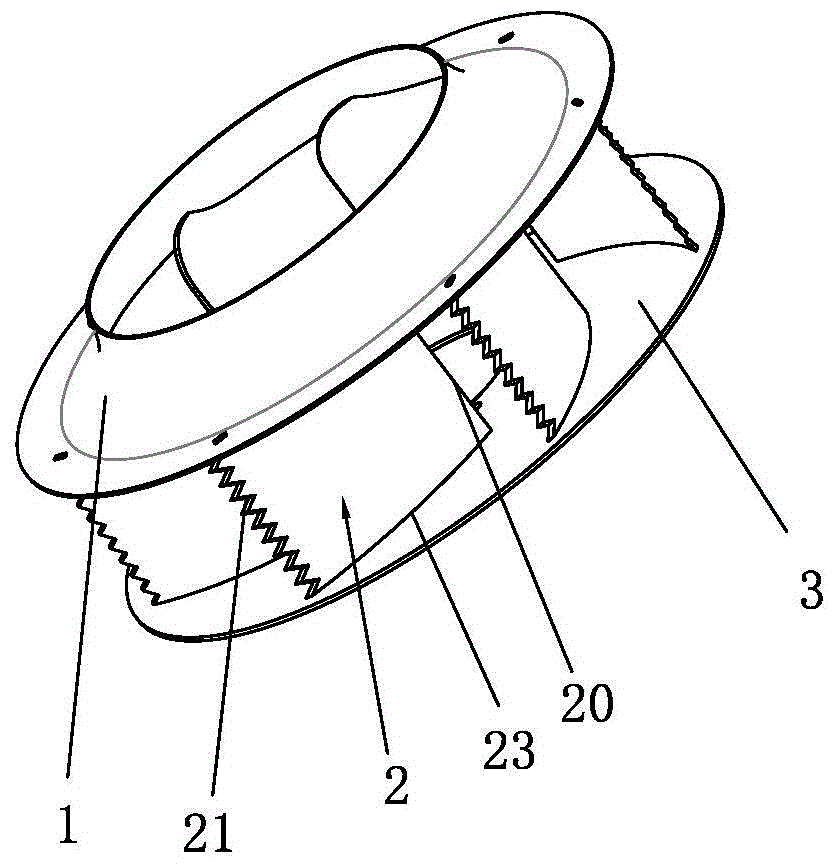

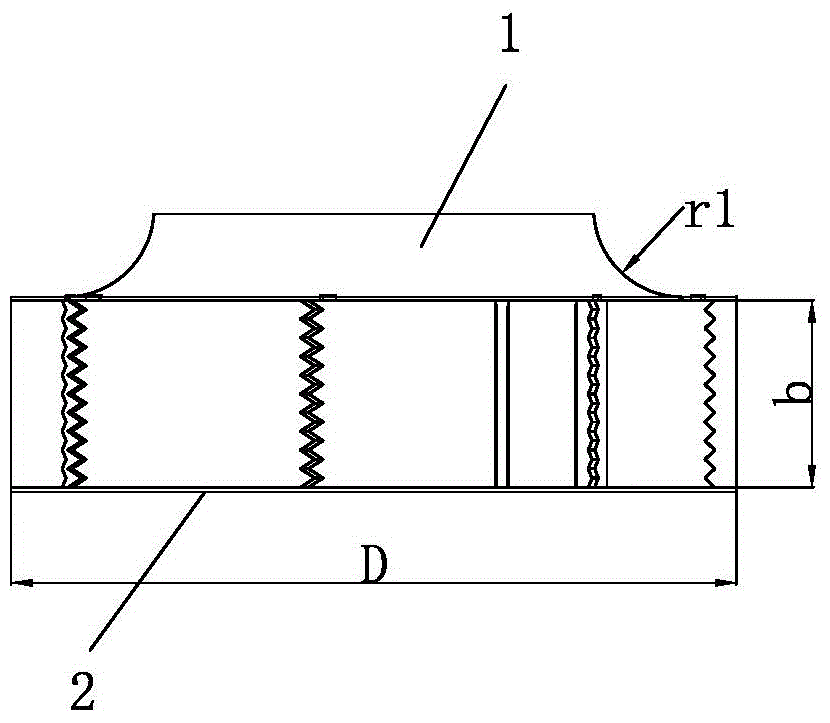

[0020] Combine below Figure 1 ~ Figure 4 The embodiment illustrates the structure of the present invention and its principle of noise reduction. The low-noise centrifugal fan impeller for the cooling system of high-speed electric multiple units in the present invention includes: a front disk 1, a rear disk 3 and a blade 2 sandwiched between the front disk 1 and the rear disk 3, the air flow flows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com