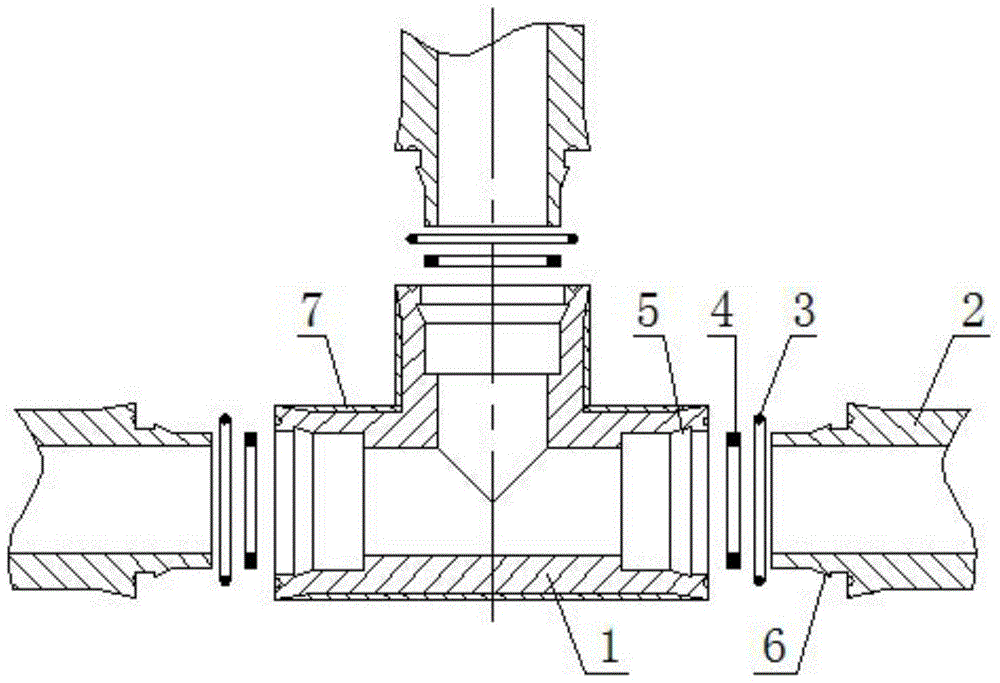

An equal-diameter pipe connection structure

A technology of equal diameter and pipe joints, applied in the field of pipeline connection, can solve the problems of increased production cost, difficult installation work, bloated shape and structure, etc., to achieve good sealing effect, reduce material consumption, and ensure the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

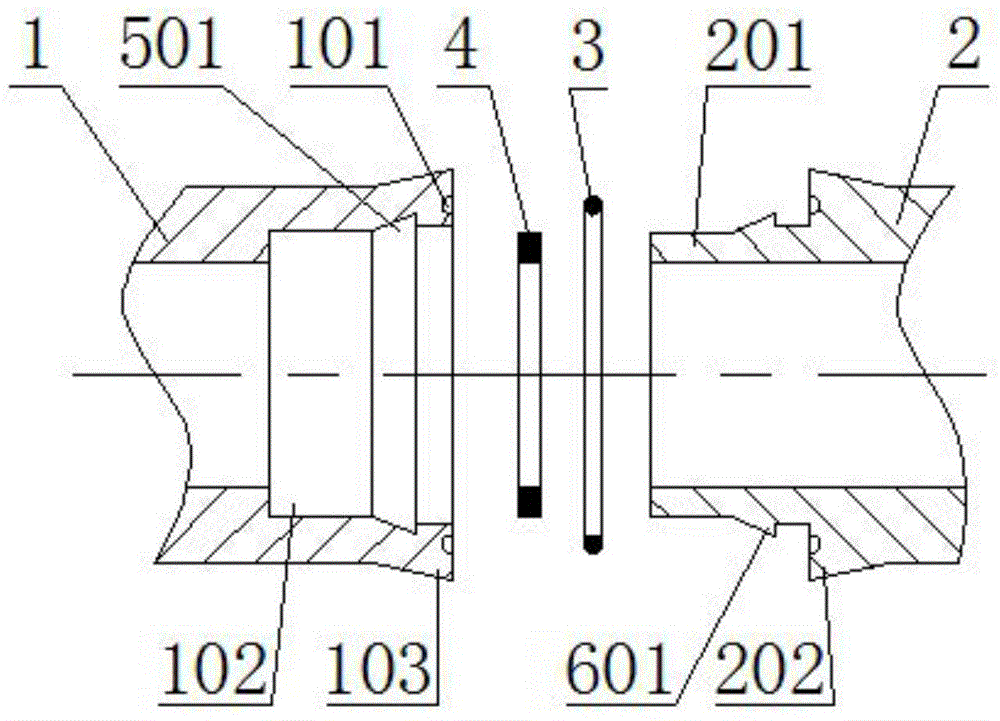

[0028] When pipe fitting 1 is connected to pipe 2, such as figure 2 , image 3 As shown, first put the inner sealing ring 4 on the end surface of the inner step 102 of the pipe fitting, and at the same time install the outer sealing ring 3 into the sealing groove 101 of the pipe fitting 1, and insert the outer step 201 of the pipe into the inner step 102 of the pipe fitting in parallel. When the inclined surface of buckle A601 is in contact with the inner edge of the pipe joint end 103, push the pipe 2 hard. Using the characteristics of good toughness of the plastic material, the pipe joint end 103 expands, the outer step 201 of the pipe shrinks, and the buckle A601 enters the groove A501. To achieve clamping, at the same time, the end surface of the outer step 201 of the pipe cooperates with the end surface of the inner step 102 of the pipe fitting to compress the inner sealing ring 4, and the sealing groove 101 of the pipe fitting end 103 and the pipe fitting end 202 cooper...

Embodiment 2

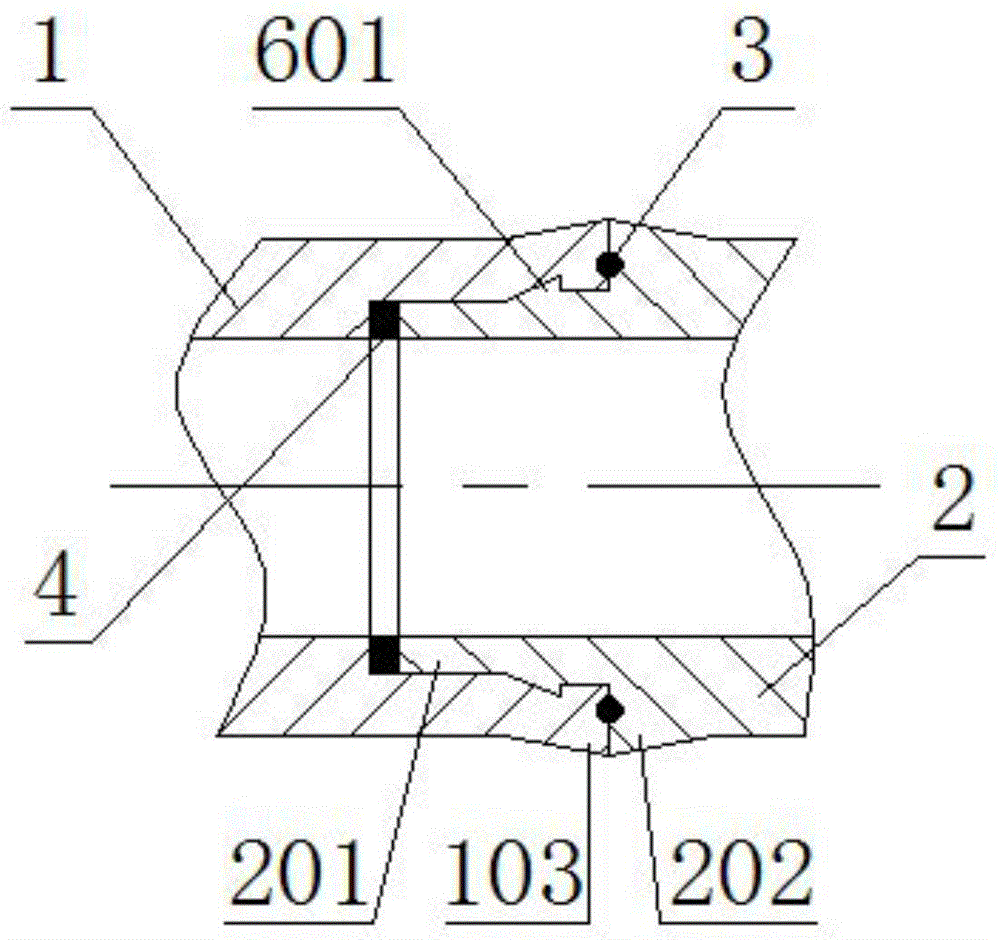

[0030] When pipe fitting 1 is connected to pipe 2, such as Figure 4 , Figure 5 As shown, first put the inner sealing ring 4 flat on the end surface of the inner step 102 of the pipe fitting, and at the same time install the outer sealing ring 3 into the sealing groove 101 of the pipe fitting 1, and insert the outer step 201 of the pipe into the inner step 102 of the pipe fitting in parallel. When the curved surface of buckle B602 is in contact with the inner edge of the pipe fitting end 103, push the pipe 2 hard. Using the characteristics of good toughness of the plastic material, the pipe fitting end 103 expands, the outer step 201 of the pipe shrinks, and the buckle B602 enters the groove B502 , to achieve clamping, and at the same time, the end surface of the outer step 201 of the pipe cooperates with the end surface of the inner step 102 of the pipe fitting to compress the inner sealing ring 4, and the sealing groove 101 of the pipe fitting end 103 and the pipe fitting e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com