Secondary air blowing and chemical feeding combined structure of biomass boiler

A technology of biomass boiler and combined structure, which is applied in the direction of non-flammable liquid/gas transportation, combustion method, combustion equipment, etc., to achieve the effects of avoiding black smoke, improving thermal efficiency, reducing wear and ash accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

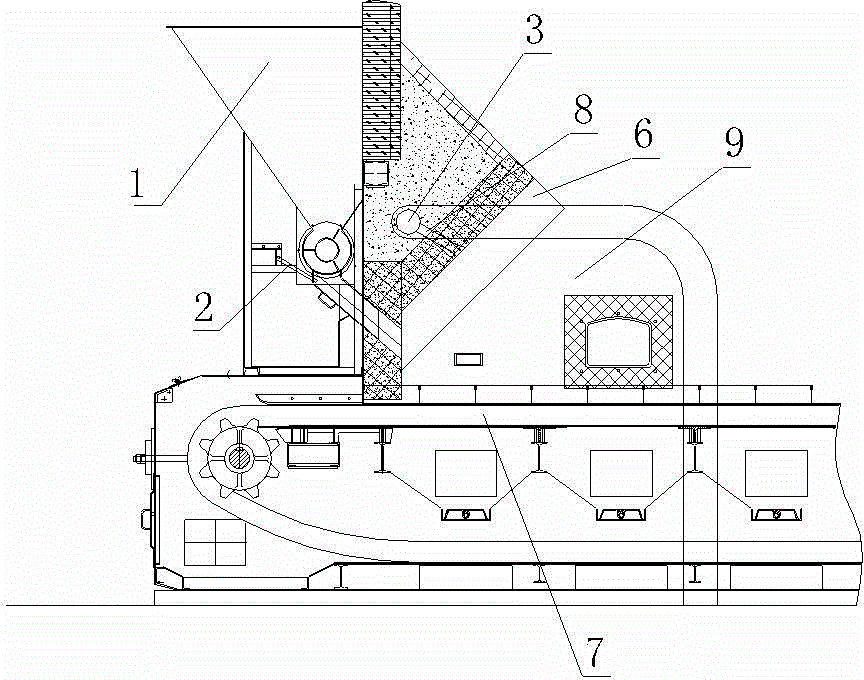

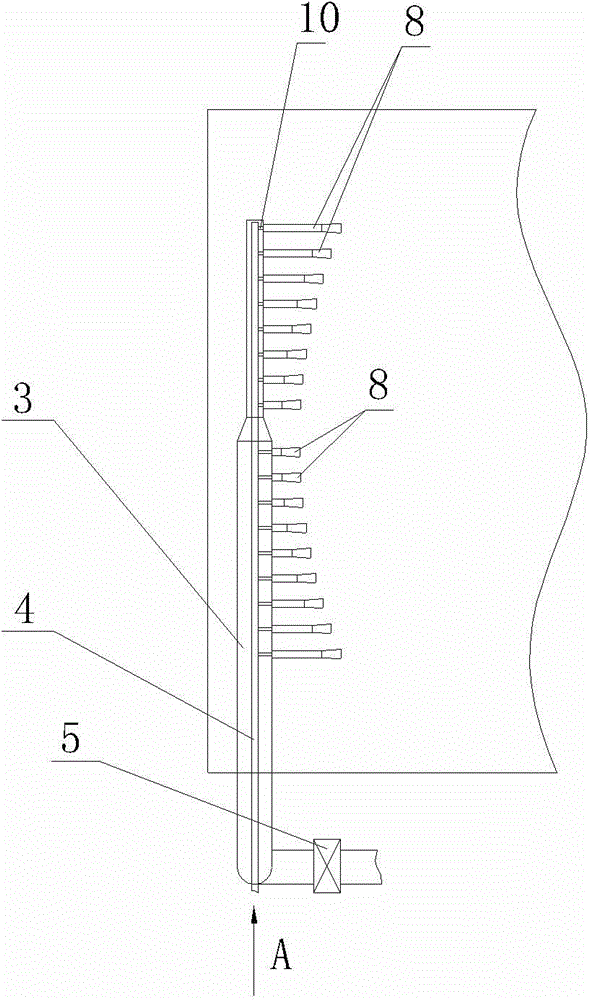

[0014] See figure 1 and figure 2 , there is a secondary air blowing device at the front arch 6 of the furnace of the biomass boiler, and a drug delivery structure is also arranged in the secondary air spraying device. While the flue gas is disturbed, the dosing structure sprays combustion aids into the furnace. The combustion aid can be one or a combination of combustion aids, catalysts, and cracking agents

[0015] Wherein, the secondary blowing device comprises a secondary blowing pipe 3 and several nozzles 8, and several nozzles 8 are vertically installed on the secondary blowing pipe 3 along the length direction of the secondary blowing pipe air pipe 3, and several nozzles 8 pass through the furnace The front arch 6 communicates with the furnace 9;

[0016] The dosing structure includes a dosing tube 4, the dosing tube 4 is set in the secondary air spray pipe 3, and the dosing pipe 4 is provided with a number of drug delivery connectors 10, which are in one-to-one comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com