Multi-heat-source single-pipe waste heat utilization heat supply system

A heating system and multi-heat source technology, applied in heating systems, hot water central heating systems, household heating, etc., can solve the problems of large initial investment, waste of pipes, and inconvenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

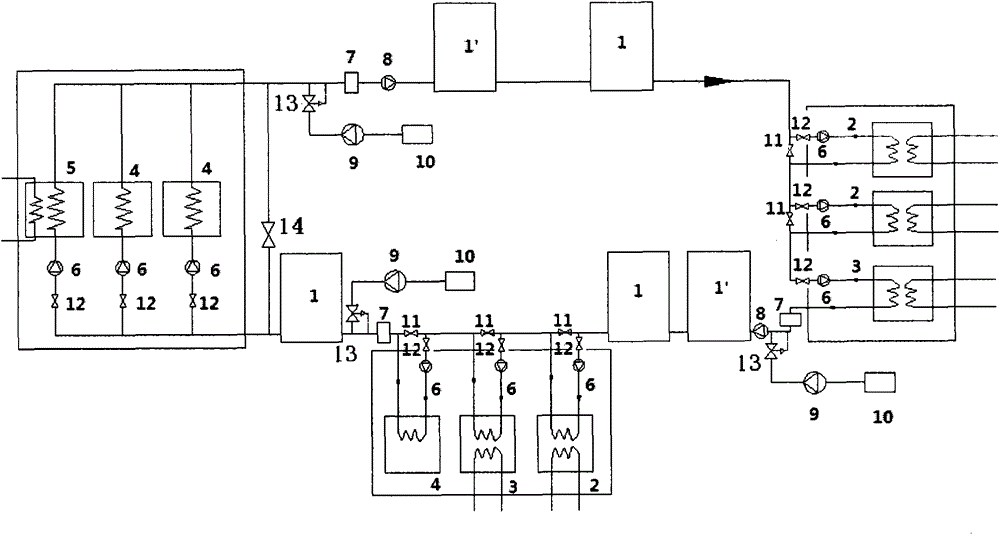

[0015] like figure 1 As shown, the present invention provides a multi-heat source single-pipe waste heat utilization heating system, including multiple heat sources 1 and 1', a single-pipe heating network and a heat station, wherein the heat station includes an energy station 2, an intermediate supply station 3, and a direct supply station. One and / or more of station 4 and large temperature difference thermal station 5, the outlet of the initial heat source is connected to the entrance of the thermal station through the single-tube heating network, and the thermal station is connected in series to the single-tube heating network, and the heat source and the thermal station alternate Connected in series at intervals, the inlet pipeline of the thermal station is provided with an independent circulating water pump 6, and the outlet of the thermal station is connected to the inlet of the next-level thermal station through a single-pipe heating network, or connected to the return wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com