Novel hybrid refrigeration cycle system

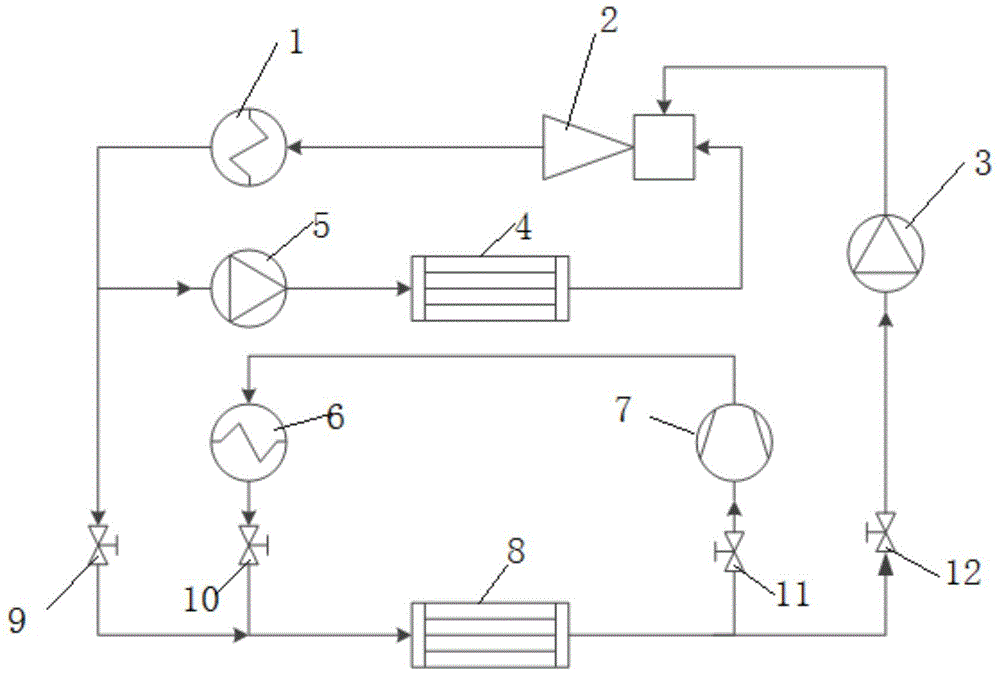

A hybrid refrigeration and circulation system technology, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of reducing system energy efficiency loss, low energy utilization rate, additional energy consumption, etc., to reduce energy consumption, improve Utilization, quantity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

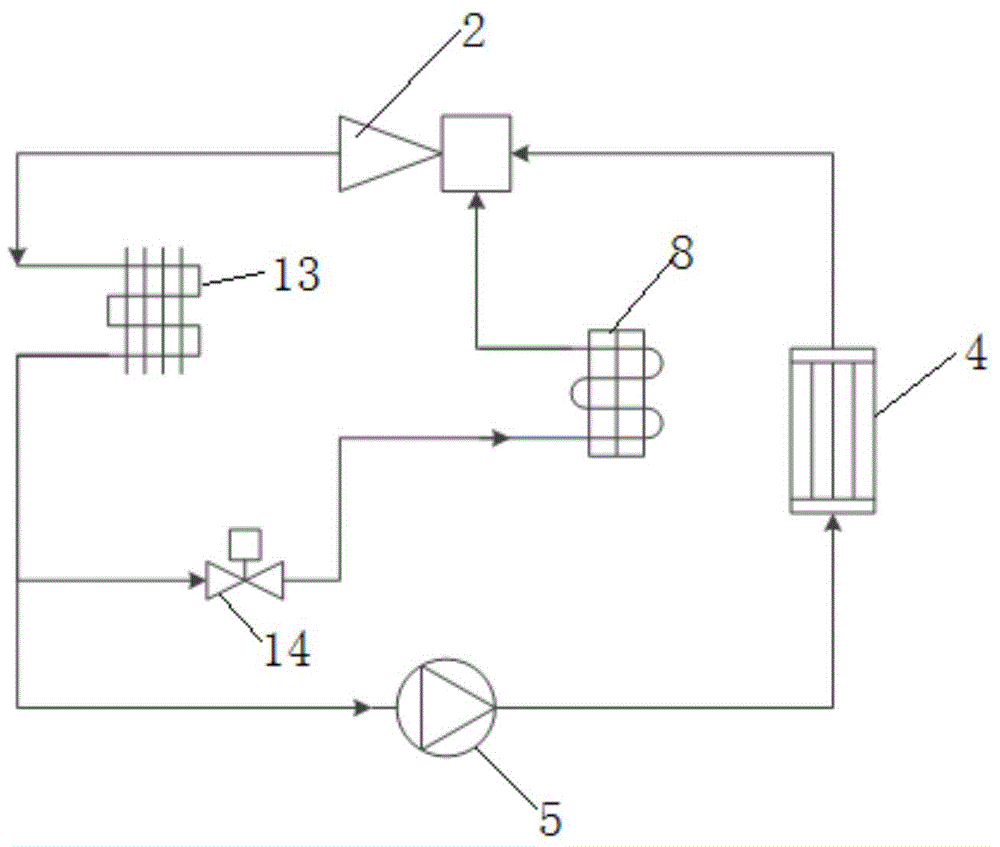

[0023] Such as figure 2 As shown, the working principle of the traditional ejector refrigeration cycle is as follows: in the generator 4, the liquid refrigerant absorbs heat, vaporizes, pressurizes, and generates high-temperature and high-pressure saturated steam. Saturated steam enters the ejector 2, expands at high speed through the nozzle, and generates low pressure or vacuum near the nozzle, so that the low-pressure and low-temperature steam in the evaporator 8 is sucked into the ejector 2. The primary flow and secondary flow in the ejector 2 are mixed and pressurized in the ejector 2 to generate high-temperature and medium-pressure saturated gas, and the mixed high-temperature and medium-pressure gas from the ejector 2 enters the condenser 13 to release heat and cool down. The condensed liquid refrigerant flows out, enters the dry liquid receiver, is dried and filtered,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com