Drying and dispersing device for wet powder materials

A drying and wet powder technology, applied in the direction of drying solid materials, drying gas arrangement, drying, etc., can solve the problems of affecting the dryness of powder materials, easy agglomeration of wet powder materials, and unfavorable complete drying, etc., to achieve low cost and dry Good performance and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

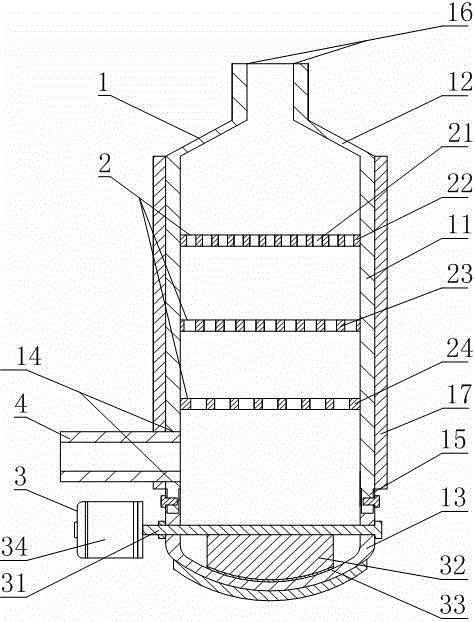

Embodiment 1

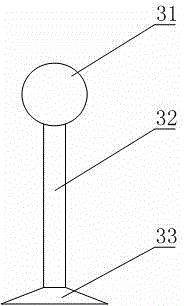

[0017] Such as figure 1 As shown, the drying and dispersing equipment for wet powder includes a drying cylinder 1, a plurality of sieve plates 2 and an anti-sedimentation rotating assembly 3. The drying cylinder 1 includes a cylinder body 11 with openings at both upper and lower The top cover 12 on the upper end surface of the body 11 and the cylinder bottom 13 fixedly connected to the lower end surface of the cylinder body 11, the lower part of the side wall of the cylinder body 11 is provided with a feed port 14 penetrating through the inner and outer walls of the side wall, and the top cover 12 is provided with a The discharge port 16 on the end face, the anti-sinking rotating assembly 3 includes a rotating rod 31 that can rotate along the axis, a connecting plate 32 that is fixedly connected to the circumferential surface of the rotating rod 31, a scraper 33 that is fixedly connected to the lower end surface of the connecting plate 32, and a driving Rotating rod 31 rotates...

Embodiment 2

[0020] This embodiment makes the following further limitations on the basis of Example 1: the sieve plate 2 includes an upper sieve plate 22, a middle sieve plate 23, and a lower sieve plate 24 distributed longitudinally from top to bottom, and the lower sieve plate 24 Located above the feed port 14. In this embodiment, the lower sieve plate 24 is located above the feed port 14, so that the agglomerated wet material deposited on the cylinder bottom 13 can be dried by the hot air at the feed port 14 through the anti-sedimentation rotating assembly 3 and move upward with the air flow.

Embodiment 3

[0022] In this embodiment, on the basis of Embodiment 1, further limitations are made as follows: among the plurality of sieve plates 2 , the distance between every two adjacent sieve plates 2 gradually decreases from top to bottom. In this example, because the aperture diameter of the upper sieve hole 21 of the middle sieve plate 23 is larger than that of the upper sieve hole 21 of the upper sieve plate 22, the material is easy to pass through the middle sieve plate 23 under the action of the hot air flow and the induced draft fan air flow but not easy to pass through the upper sieve plate 22. Sieve plate 22. At this time, the material tends to stay in the area between the middle sieve plate 23 and the upper sieve plate 22. In order to avoid clogging, the distance between the lower sieve plate 24 and the middle sieve plate 23 is smaller than the distance between the middle sieve plate 22 and the upper sieve plate 22. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com