A method for correcting deviation of backwater flow detection

A technology of deviation correction and return water flow, which is applied in the application of electromagnetic flowmeters to detect fluid flow, liquid/fluid solid measurement, volume/mass flow generated by electromagnetic effects, etc. Problems such as automatic commissioning of the circuit and inability to provide guidance for production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] The present invention will be further described below in conjunction with the accompanying drawings.

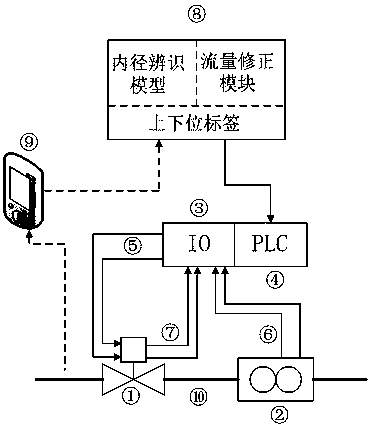

[0105] as attached figure 1 As shown, the self-cleaning electromagnetic flow regulating valve 1 and the self-cleaning electromagnetic flowmeter 2 are installed on the return water delivery pipeline 10, wherein the regulating valve position feedback signal 7 of the self-cleaning electromagnetic flow regulating valve 1 and the self-cleaning electromagnetic flowmeter 2 The process detection flow is connected to the PLC system 4 through the IO module 3, and the centralized monitoring is carried out in the upper monitoring machine 8 through the communication bus.

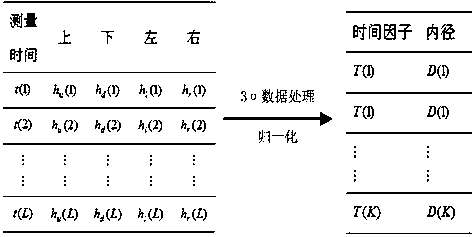

[0106] In order to realize the return water flow deviation caused by slow time-varying diameter reduction, a portable ultrasonic thickness gauge 9 is used to detect the upper, lower, left and right wall thicknesses of the same vertical section of the flowmeter. In order to ensure the accuracy of measurement, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com