A Method for Measuring the Heat Flux and Temperature of the Hot Surface of the Crystallizer

A heat flux density and crystallizer technology, applied in the direction of measuring heat, thermometers, measuring devices, etc., can solve the problem of inability to accurately calculate the heat flux density and temperature of the hot surface of the crystallizer, the difficulty in calculating the convective heat transfer coefficient of the cooling water tank, and the inability to obtain the crystallizer wall temperature changes etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

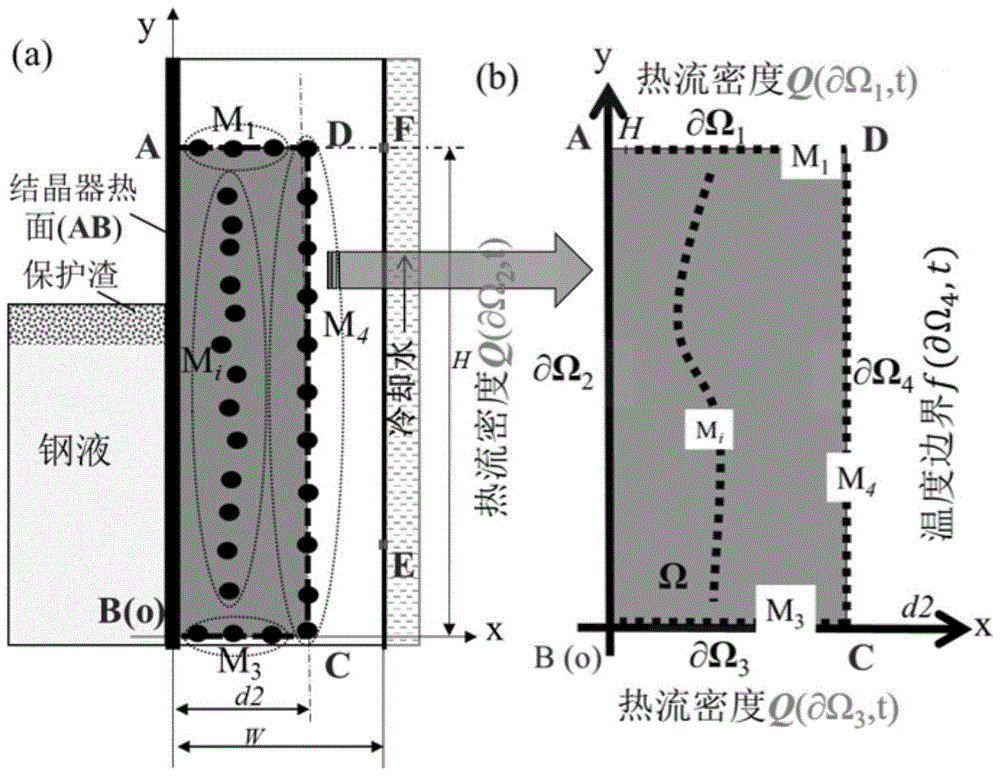

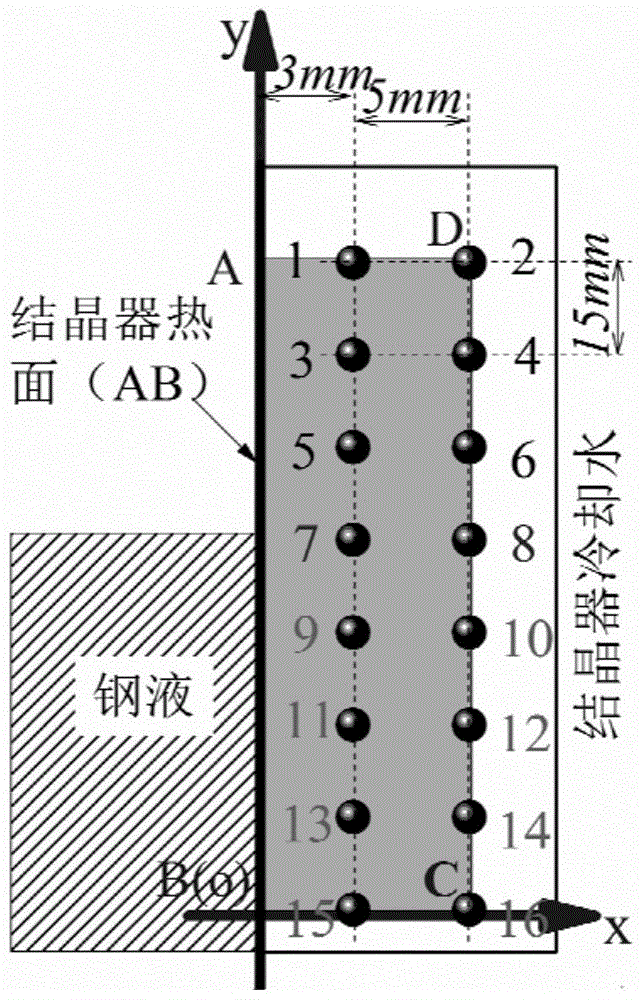

[0115] In the continuous casting process of medium carbon steel, in the longitudinal section of the mold wall, the vertical mold hot surface ( image 3 side AB in the center), the height is H=105mm, and the width is d 2 = 8 mm rectangular area ABCD with vertical side AB on the mold hot face and vertical side CD inside the mold wall. Select the rectangular area ABCD as the mathematical calculation domain, and record it as Ω, and let B be the origin (x=0mm, y=0mm), so the coordinates of A are (x=0mm, y=105mm); Ω has four boundaries, The upper and lower boundaries AD and BC of Ω are respectively denoted as with The left and right boundaries AB and CD are denoted as with at the border with Install M on 1 = 2, M 3 = 2 and M 4 = 8 T-type thermocouples; M is installed in the calculation domain Ω i = 8 T-type thermocouples. The thermocouple has a diameter of 0.8mm and is installed on two vertical lines respectively, one of which is 3mm from the thermocouple to the hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com