Austenitizing determination method in metal material heat treatment process

A technology of heat treatment process and metal materials, applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of inability to obtain the experimental data of thermal properties of materials at high temperature stage, experimental conditions, etc., and achieve scientific support for the heat treatment process. , the effect of heat treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

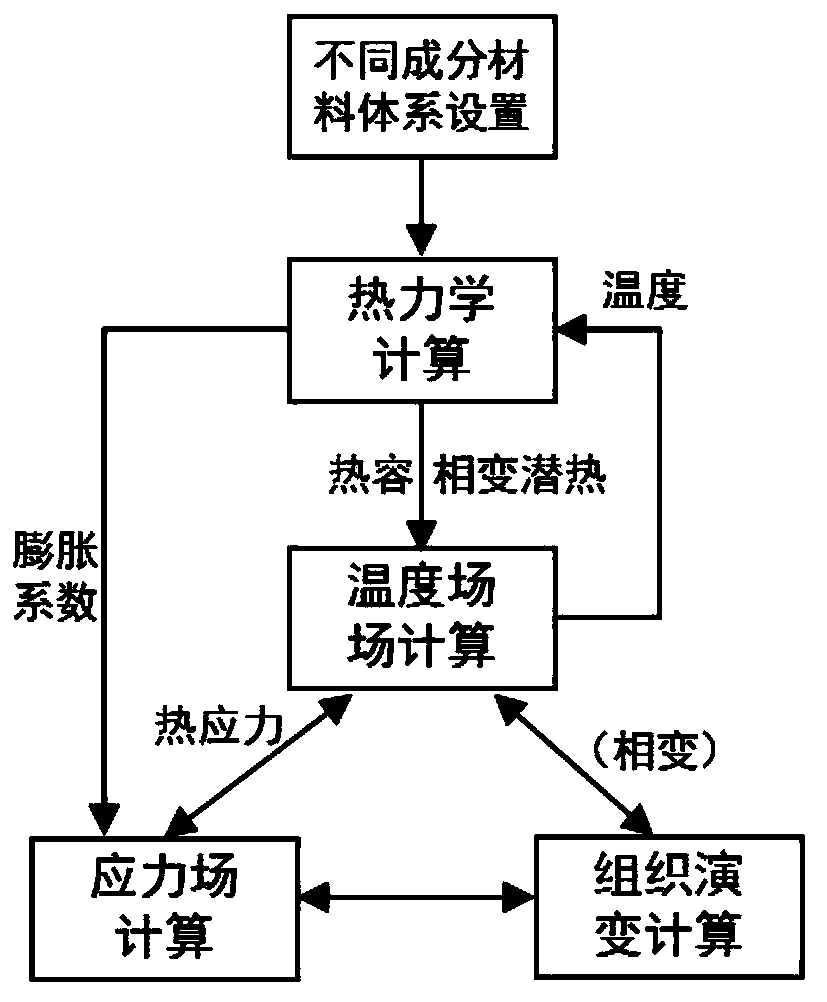

[0098] Taking the calculation of the flat plate welding process of the composition steel in Table 1 as an example, using the above-mentioned multi-field coupling integrated calculation method of thermodynamics and finite element, an example is carried out for the multi-field coupling calculation process of temperature field, stress field and tissue field Operational process demonstrations and instructions, such as Figure 1 to Figure 10 Shown:

[0099] Table 1 Composition content and phase transition temperature of composition steel

[0100] Element

C

Si

mn

Fe

T-A3(°C)

wt%

0.10

0.2

1.4

Rest

830.2

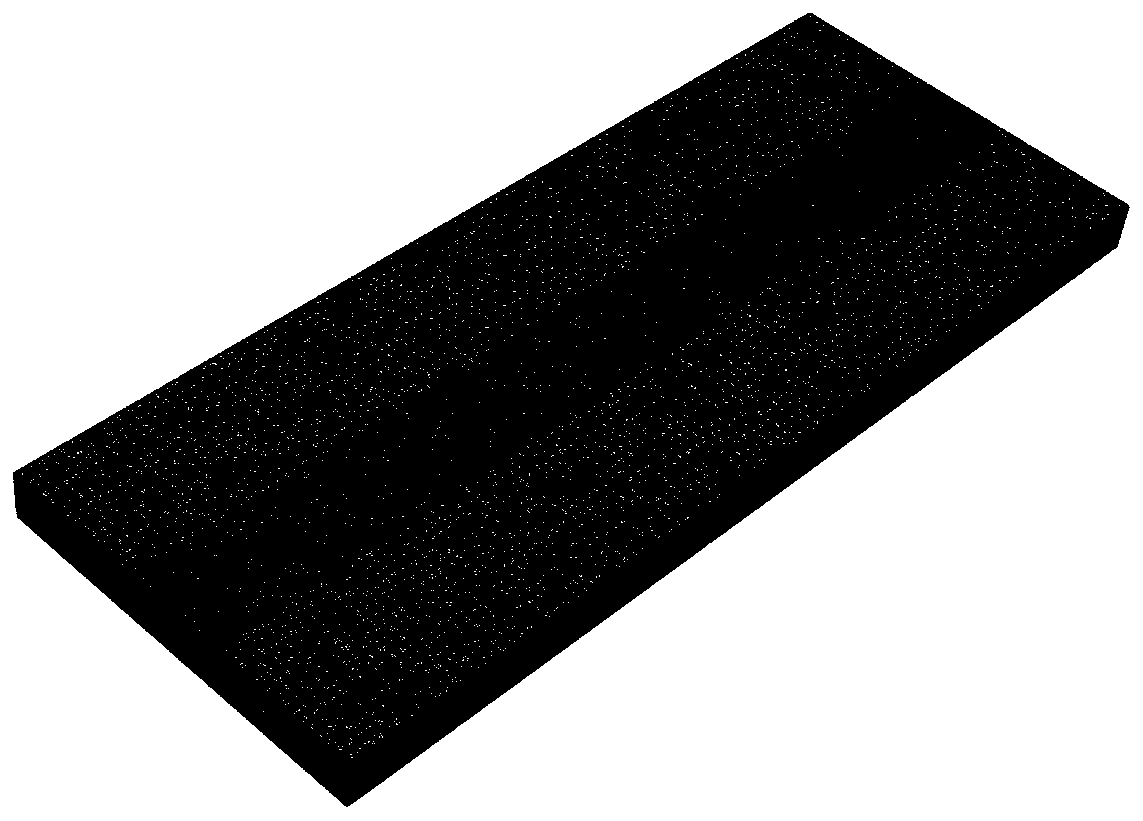

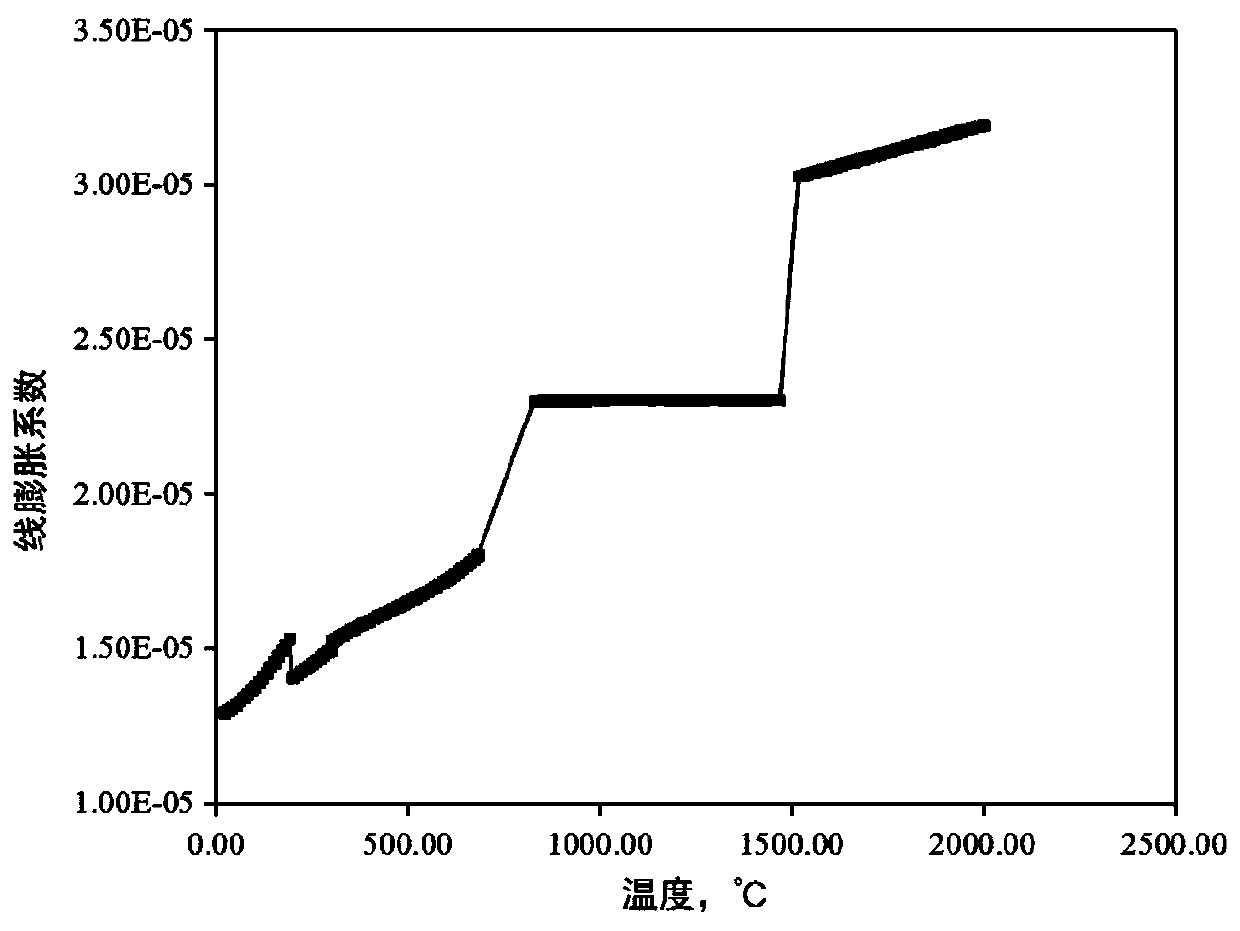

[0101] First, establish a three-dimensional plate butt welding model and divide the mesh, such as Figure 5 shown. It is necessary to set the density, thermal conductivity, elastic modulus, yield strength and other parameters of the material, and the material parameters heat capacity and thermal expansion coefficient (such a...

Embodiment 2

[0104] Taking the calculation of the austenitization process of a steel with a certain upper and lower limit composition in Table 2 as an example, for the above-mentioned multi-field coupling integrated calculation method of thermodynamics and finite element, when the thermal stress calculation is not considered, only the temperature field and The coupling calculation of the tissue field obtains the phase transition under the condition of thermodynamic equilibrium state, and demonstrates and explains the operation process of the example:

[0105] Table 2 Composition of steel and the upper and lower limits of its content

[0106] Element

[0107] First, model the austenitization process of the 300mm*120mm two-dimensional slab in the finite element general software, input the thermophysical parameters of the material, and the heat transfer coefficient in the heating furnace, and calculate the temperature field. In order to obtain the microstructure of the slab at a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com