V-shaped tube-type flue gas sampling instrument probe rod

A sampler and flue gas technology, applied in the direction of sampling devices, etc., can solve the problems of increasing production cost and increasing process difficulty, and achieve the effects of prolonging the life of the instrument, simple production method, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and illustrative examples.

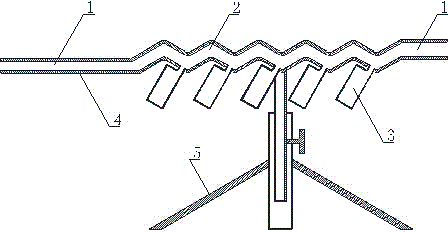

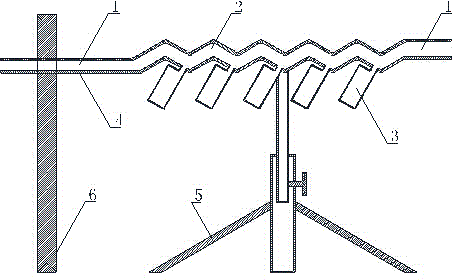

[0021] figure 1 It is a schematic diagram of the device of the probe rod of the V-tube smoke sampler according to the embodiment of the present invention. Such as figure 1 As shown, the probe rod of the V-pipe flue gas sampler of the present invention includes a straight pipe 1 , a V-shaped pipe 2 , a dust box 3 , an insulating sleeve 4 and a support frame 5 . The straight pipe 1 and the V-shaped pipe 2 are integrally formed and seamlessly connected to ensure airtightness. The included angle between the V-shaped pipe 2 and the front portion of the straight pipe 1 is 30°, and the bending angle of the V-shaped pipe 2 is 120°. The dust box 3 is fixed on the bottom of the descending section of each V-shaped pipe 2 by threads, and can be disassembled as required. The thermal insulation sleeve 4 covers the straight pipeline 1 and the V-shaped ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap