Interlaminar shear resistant strength testing method

A technology of interlayer shear strength and test method, which is applied in the direction of applying stable shear force to test material strength, etc., which can solve the problems of interlayer shear strength not meeting the requirements, difficult to distinguish, and completion construction failure. , to achieve the effect of avoiding completion failures and test errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the drawings and specific embodiments.

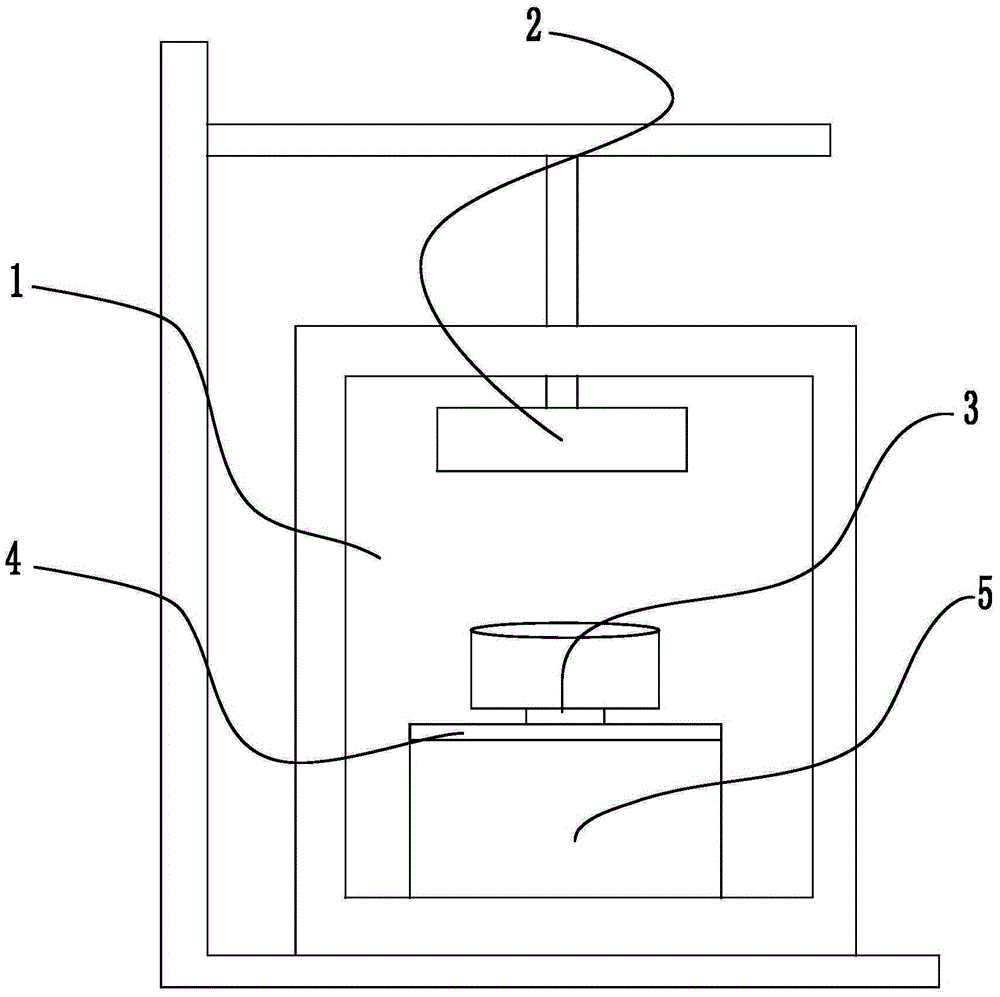

[0029] Such as figure 1 Shown is an example of an interlaminar shear resistance test device tested according to the interlaminar shear resistance test method of the present invention. In this embodiment, the fixture testing mechanism includes a temperature regulating box 1, a pressure loading machine 2, a pressure loading block 3 and a supporting base 5. The pressure loading machine 2, the pressure loading block 3 and the supporting base 5 are all arranged in the temperature regulating box 1 within. Cut out 4-12 groups of samples 4 with a length of 5mm from the wound composite pipe along the axial direction. The sample 4 is axially placed on the support base 5, and the sample 4 is clamped by the pressure loading block 3.

[0030] The pressure loading machine 2 pressurizes the sample 4 equipped with shear nails and hand-off tools through the pressure loading b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com