A method for judging the compactness of interface connection by spring stiffness coefficient

A stiffness coefficient and compactness technology, applied in the field of ultrasonic nondestructive testing, can solve the problems of difficult application and many thin layers, and achieve the effect of easy excitation and easy application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

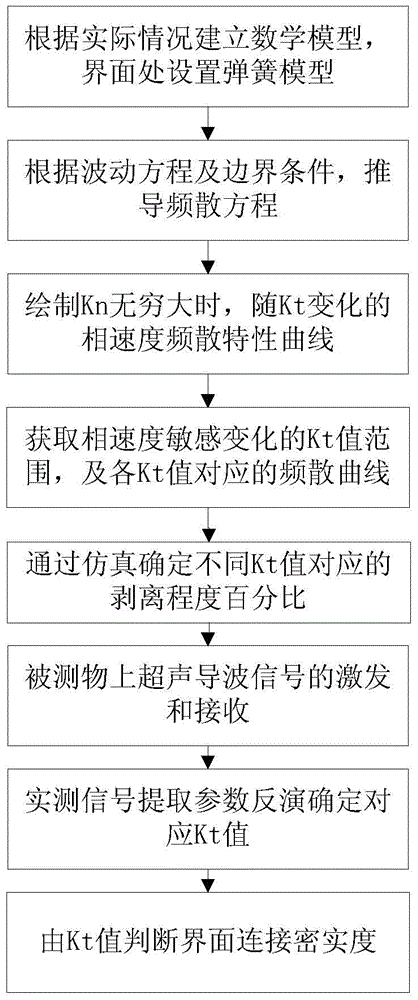

[0032] Such as figure 1 Shown is the detection flow chart of this embodiment.

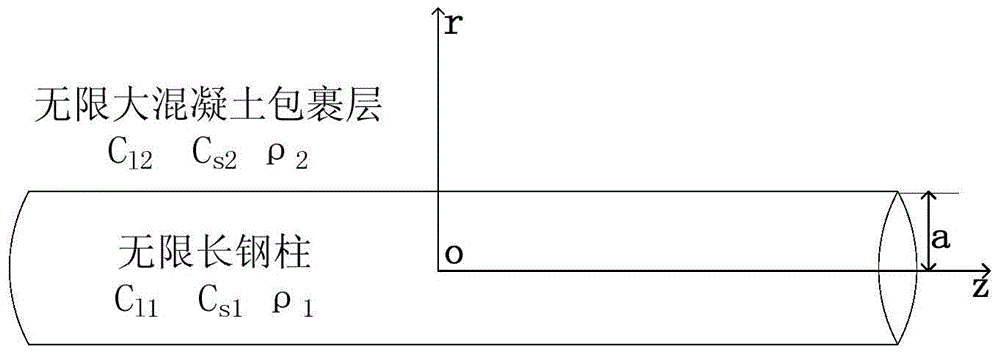

[0033] The embodiment selects an infinitely large concrete layer wrapped steel column structure, and the mathematical model set is as follows figure 2 shown.

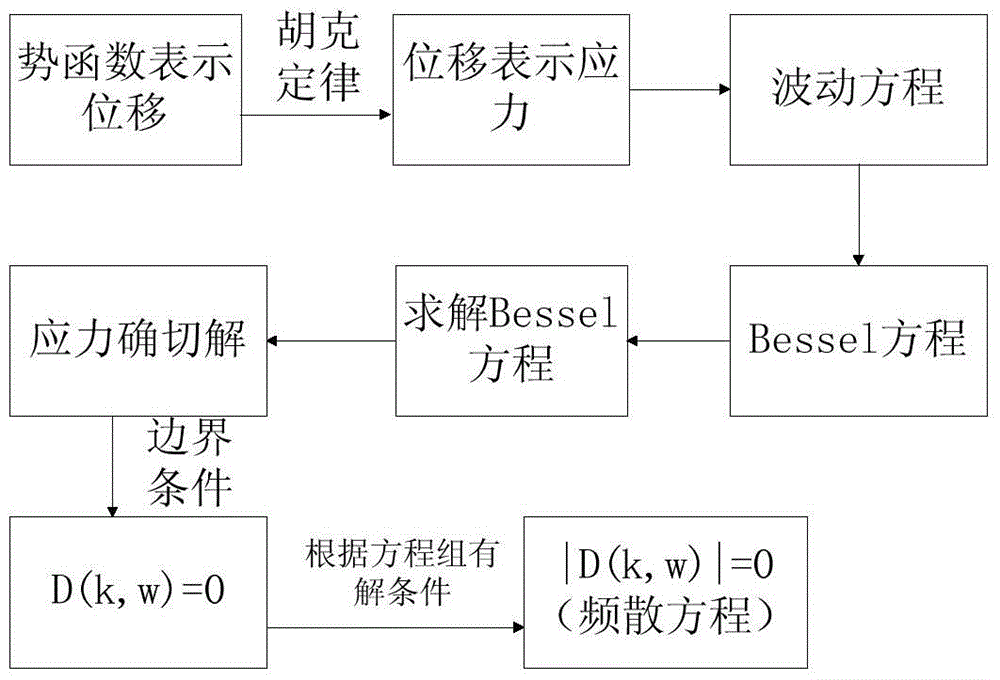

[0034] Derivation of the dispersion equation for this structure, the specific derivation process is as follows image 3 shown. The displacement potential function satisfies

[0035] u = ▿ φ + ▿ × ( χe z ) + ▿ × ▿ × ( ψe z ) - - - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com