Surface defect detection method of aluminum profiles based on machine vision

A defect detection and machine vision technology, applied in the direction of optical testing flaws/defects, to achieve the effect of maintaining corporate reputation, avoiding interference, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

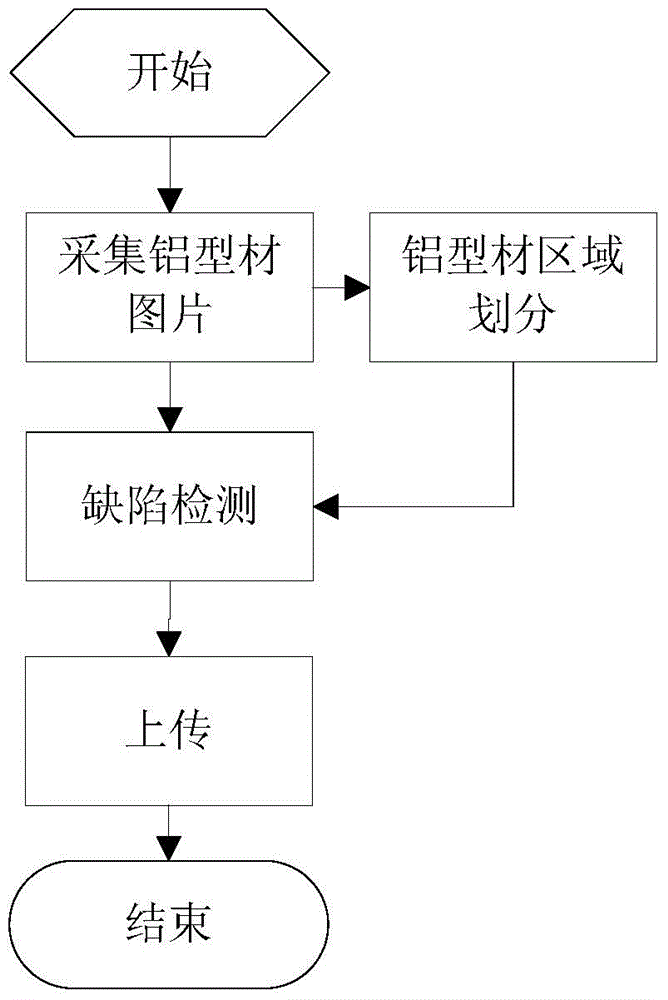

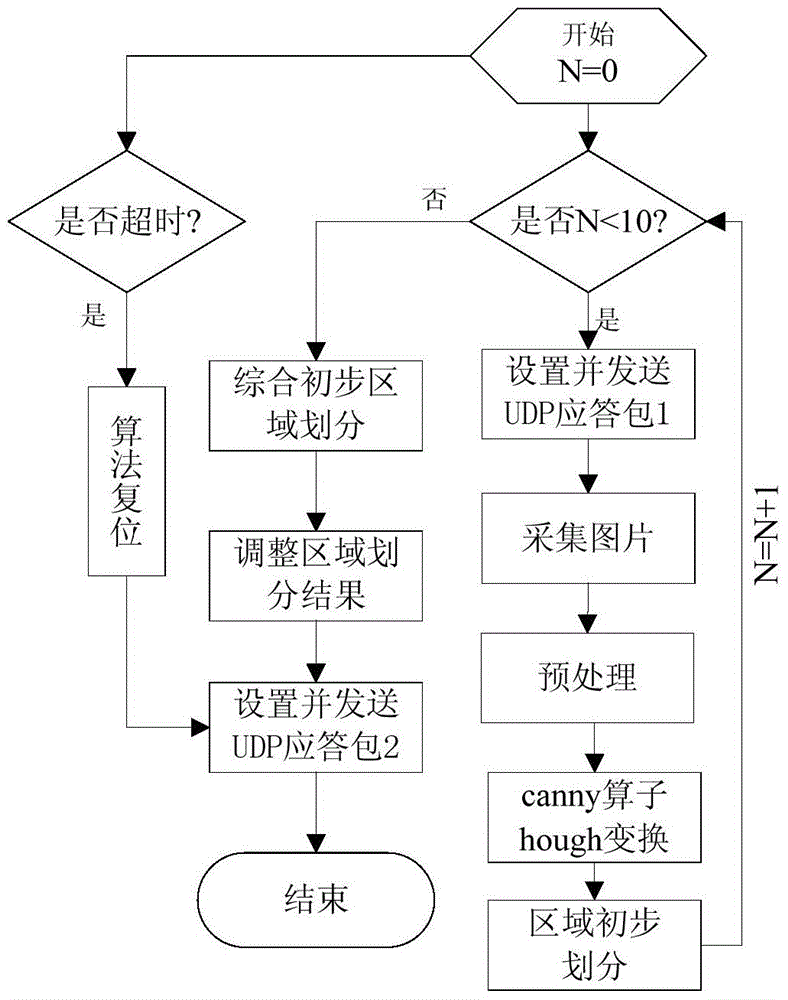

[0034] figure 1 It is the overall flow chart of the present invention, including collecting pictures of aluminum profiles, area division of aluminum profiles, surface defect detection and uploading defect information and pictures. The method of the present invention is realized by the VC4018 camera. The camera may receive four kinds of commands from the host computer, including parameter configuration command package, aluminum partition command package, defect detection command package and connection request. Parameters include Sobel parameters, Canny parameters, partition parameters, texture parameters and shutter time. When receiving the parameter setting command packet sent by the host computer, first determine what kind of parameter is to be set, and then perform the corresponding setting work to save the parameter as a system variable; if it is a shutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com