Device and method for measuring ultralow liquid flow rate

A liquid and flow rate technology, which is applied in the field of devices for measuring ultra-low liquid flow rates, can solve the problems of difficult realization of low flow rates, complicated device structure, cumbersome data processing methods, etc., and achieve the effect of avoiding signal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

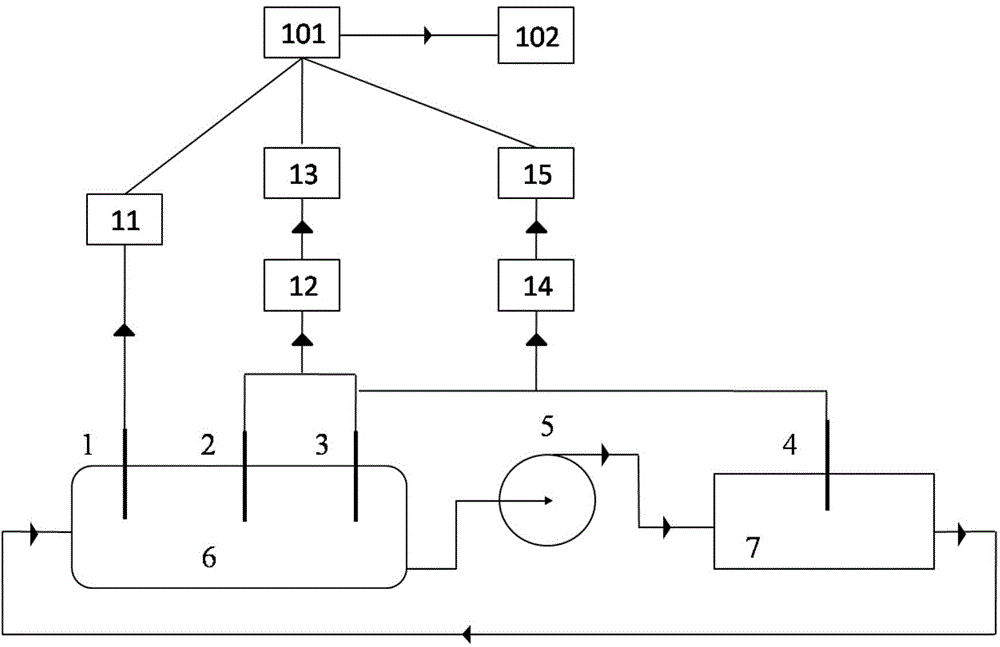

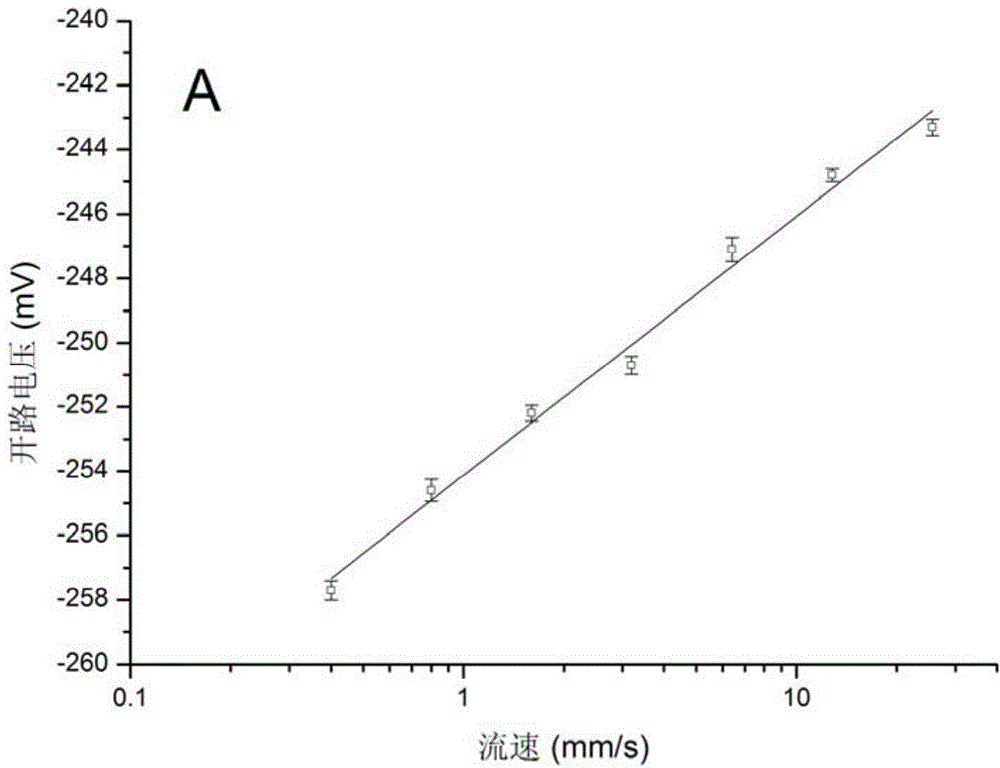

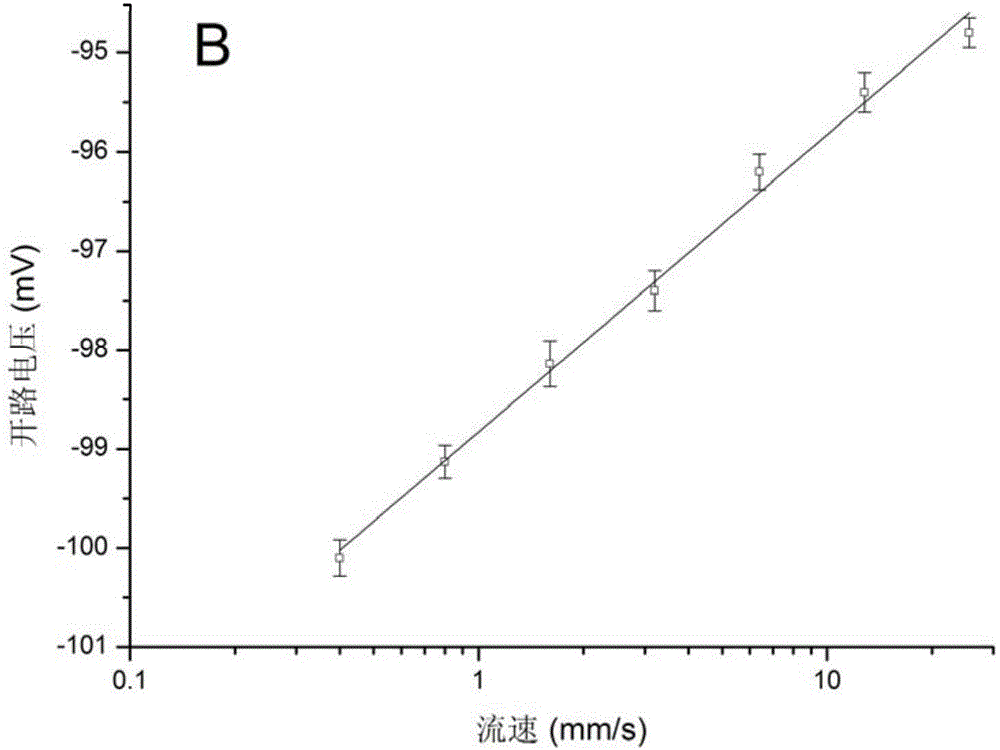

[0032] The present invention provides a method for measuring ultra-low liquid flow rates. This method is suitable for developing flow rate measurement devices in a simple, low-cost, and energy-efficient manner. The method is based on the characteristics of the tungsten oxide electrode, the surface of the tungsten oxide electrode is composed of compact WO 3 Inner layer and slack WO 3 .xH 2 O outer layer composition, when the flow rate on the surface of the tungsten oxide electrode becomes larger, this layer of loose hydration layer is thinned, resulting in a change in the electrode potential of the tungsten oxide electrode, under the same solution temperature and pH value, by measuring the oxidation The open circuit voltage between the tungsten electrode and the reference electrode can be used to obtain the potential change of the tungsten oxide electrode itself, so as to measure the ultra-low liquid flow rate. Since the electrode potential of the tungsten oxide electrode is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com