Liquid crystal module full-lamination structure

A liquid crystal module and full lamination technology, applied in light guides, optics, instruments, etc., can solve problems such as waste of light sources, achieve clear image quality, increase light utilization, and increase light incidence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better illustrate the technical features and structure of the present invention, the following detailed description is given in conjunction with the preferred embodiments of the present invention and the accompanying drawings.

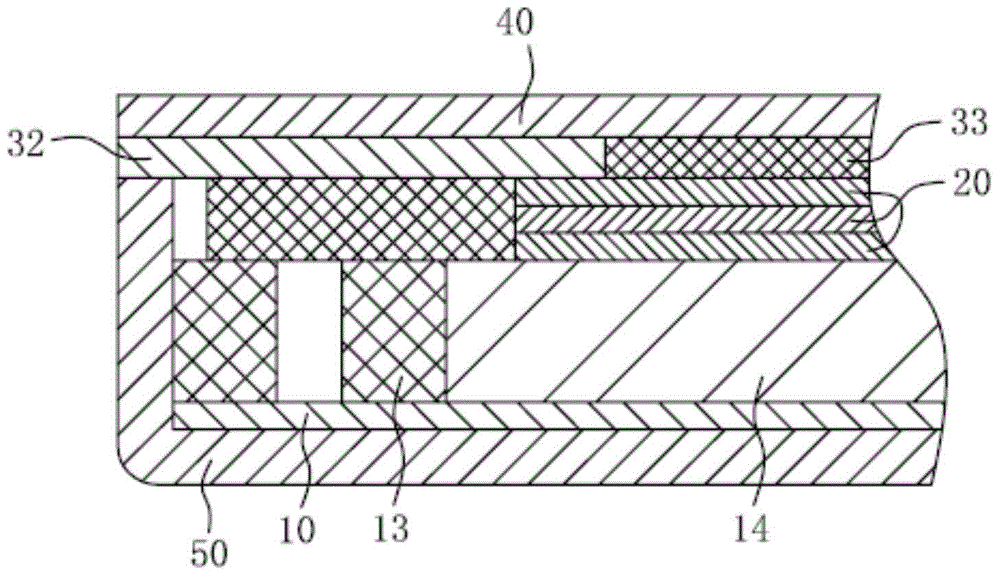

[0019] see figure 1 , a liquid crystal module fully bonded structure, including at least a housing 50, a liquid crystal panel 40, a light guide plate 14, a number of optical films 20, a reflector 10 and a light source 13, a light guide plate 14, a number of optical films 20, reflection The sheet 10 and the light source 13 are located inside the casing 50, wherein the reflective sheet 10 is located below the light guide plate 14 and is in contact with the casing 50, the light source 13 is located on the side of the light guide plate 14, and a plurality of optical films 20 are superimposed on each other. above the light guide plate 14 . The liquid crystal panel 40 is overlapped on the casing 50 . The liquid crystal panel 40 is provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com