Fire-resistant thermal isolation insulation tube

An insulating tube and heat insulation technology, applied in the direction of insulators, layered products, chemical instruments and methods, etc., can solve problems such as deformation, fire resistance degradation, and line damage, and achieve the effects of preventing damage, preventing deformation and fracture, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

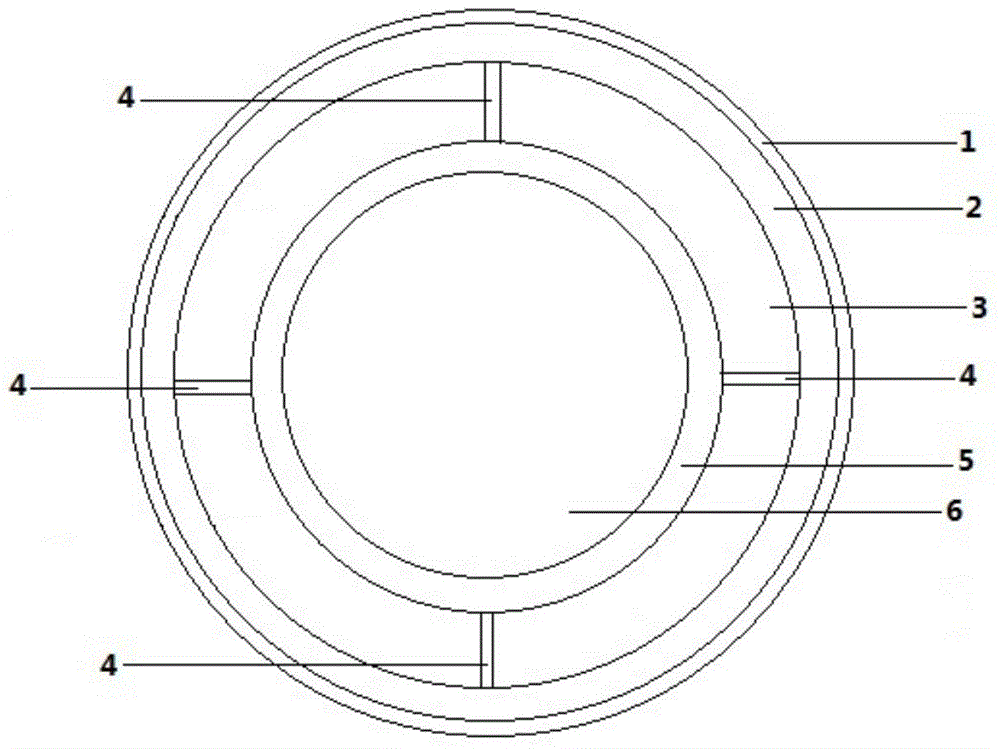

[0015] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination figure 1 The present invention is described further, but the protection scope of the present invention is not limited.

[0016] A fire-resistant and heat-insulating insulating pipe, which includes an insulating layer 5, a heat-insulating filling layer 3, a low-expansion alloy shell 2, and a fire-resistant protective material layer 1 from the inside to the outside.

[0017] A pipe support frame 4 is installed in the heat insulating filling layer 3 .

[0018] The insulating layer 5 is carbon fiber insulating material.

[0019] The thermal insulation filling layer 3 is diatomaceous earth.

[0020] The low-expansion alloy shell 2 is made of iron-nickel alloy material.

[0021] The refractory protective material layer 1 is silicon carbide.

[0022] Among them, the low-expansion alloy shell 2 can prevent the pipe body f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com