Mobile phone case and preparation method thereof

A mobile phone shell and metal substrate technology, applied in branch equipment, telephone structure, other household appliances, etc., can solve the problems of slow loading, high cost, affecting development progress, etc., to reduce time, weight, and material output. effect of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

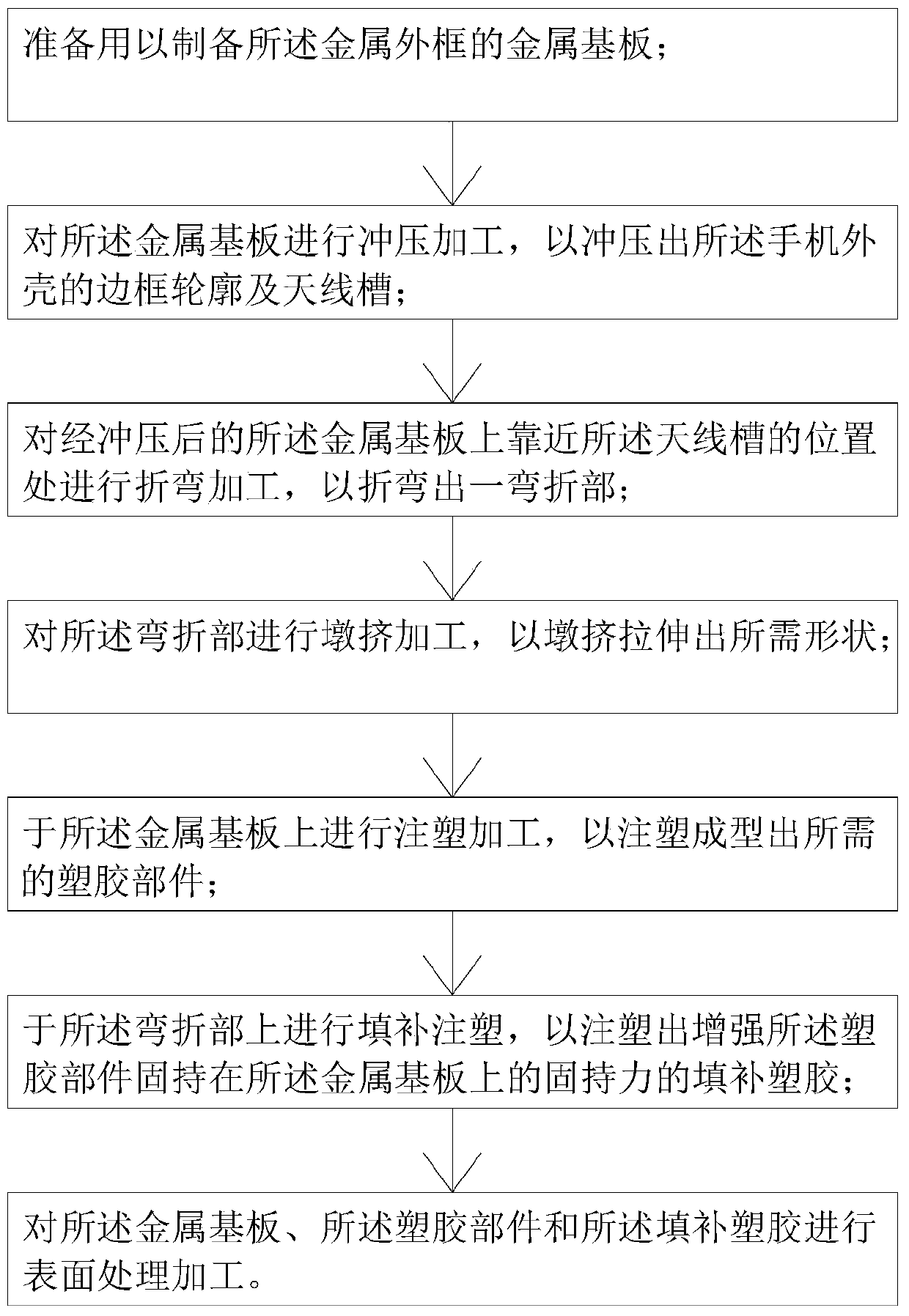

[0034] see Figure 1 to Figure 6 , the preparation method of the mobile phone shell that the present embodiment provides, comprises the following steps:

[0035] S1, the material preparation process, preparing the metal substrate 10 for preparing the mobile phone case 100, wherein the material of the metal substrate 10 is stainless steel, aluminum or aluminum alloy, so as to ensure that the metal substrate 10 has better strength and appearance processing surface , and it is also beneficial to produce various appearance effects, such as brushed, high-gloss, etc.;

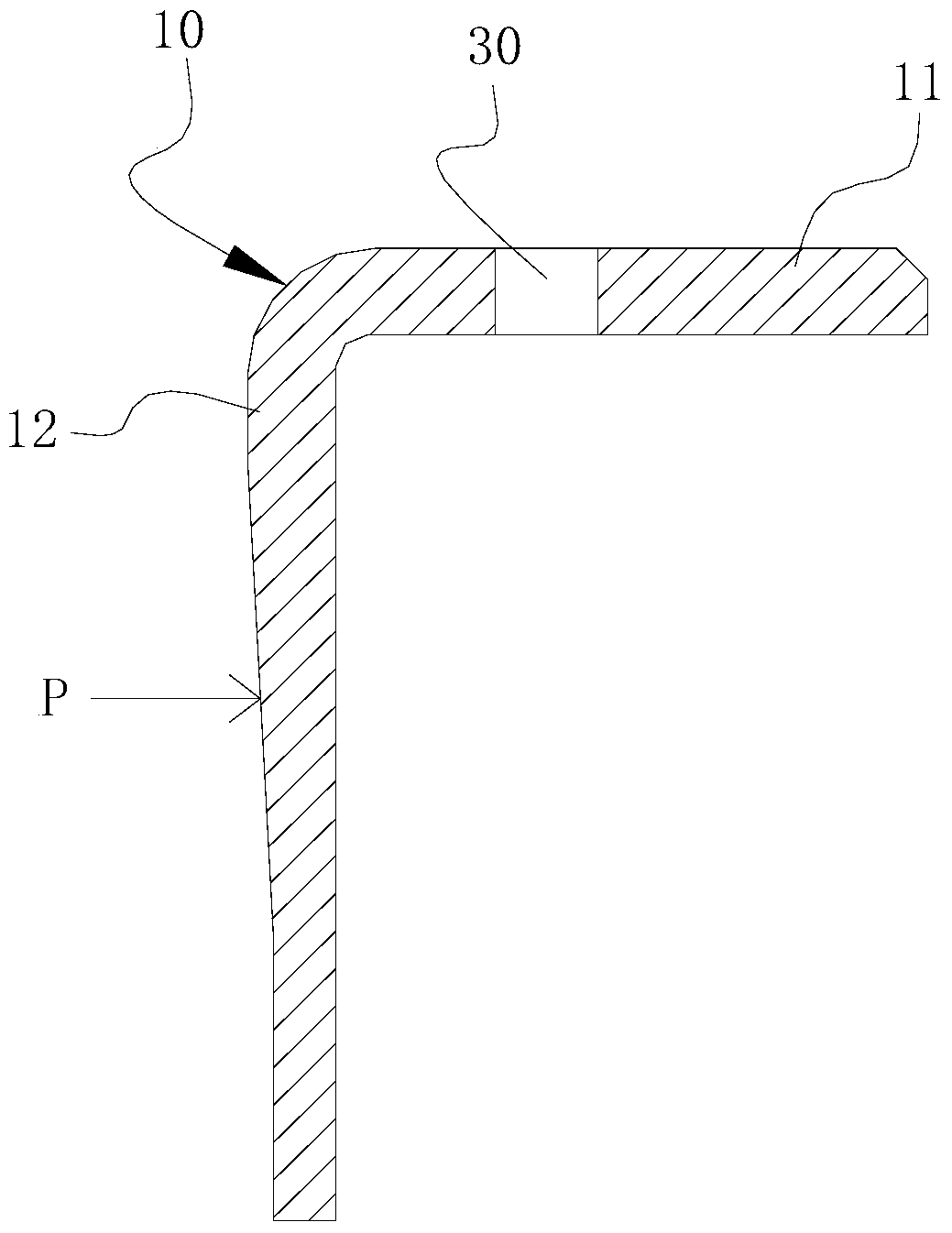

[0036] S2, the stamping process, the metal substrate 10 is stamped to stamp out the frame outline of the mobile phone casing 100 and the antenna slot 30 for installing the antenna, the frame outline on the metal substrate 10 includes a first side 11 and a second side 12 , specifically, the antenna slot 30 is provided on the first side 11;

[0037] S3, the bending process, because in the previous process, in order t...

Embodiment 2

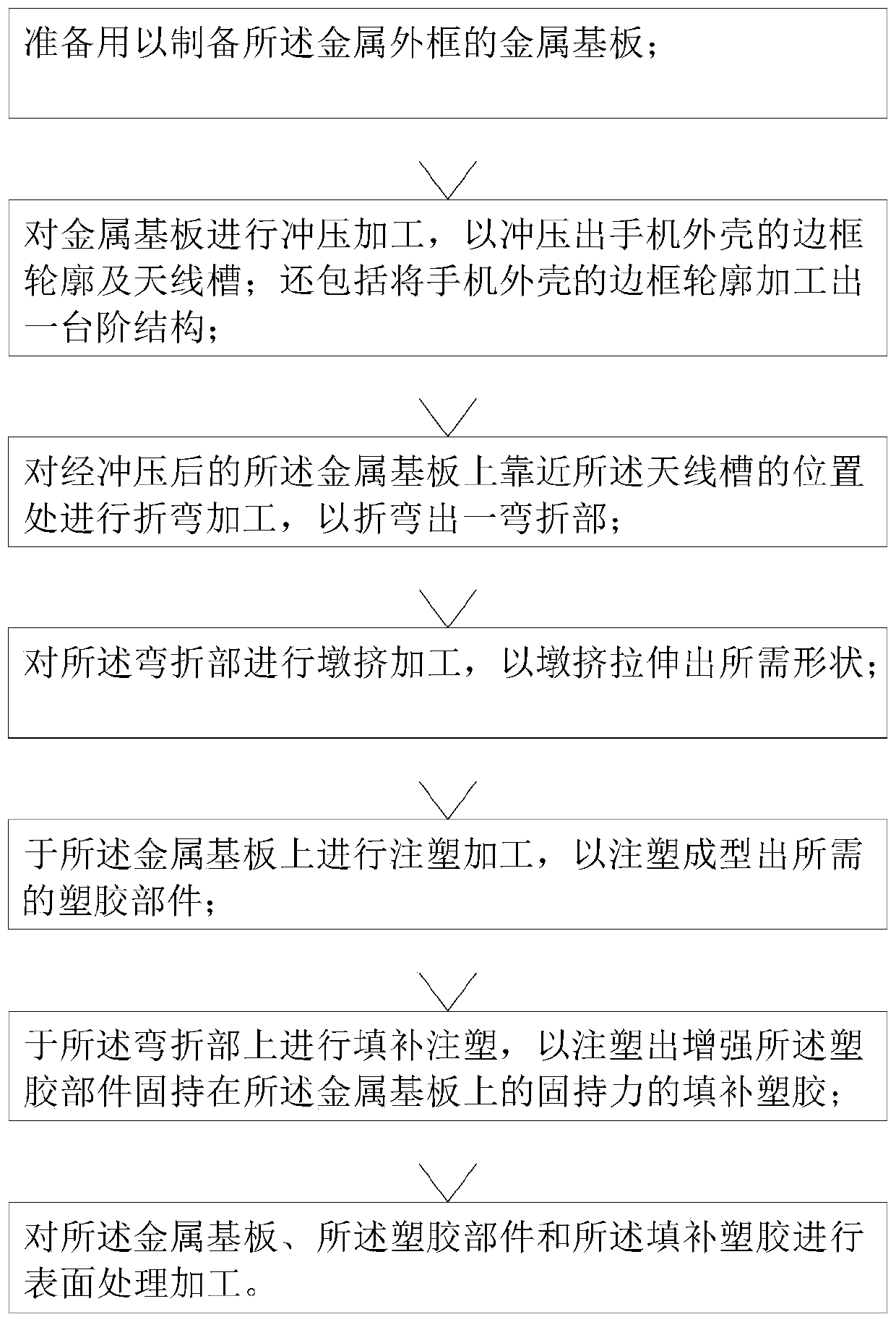

[0054] see Figure 7 , and combined with Figure 3 to Figure 6 , the embodiment of the second embodiment is similar to the embodiment of the first embodiment. For details, refer to the embodiment of the first embodiment, which will not be described in detail here. The difference between the two lies in the processing procedure of the step structure 14. The specific embodiment of the second embodiment for:

[0055] A step structure 14 is processed out of the frame outline of the mobile phone casing 100 and placed on the stamped metal substrate 10 near the antenna groove 30 for bending processing. In this way, the step structure 14 and the bent structure can be formed at one time through the mold. The folding part 13 is completed at the same time, which can save processing time and reduce processing cost.

Embodiment 3

[0057] see Figure 8 , and combined with Figure 3 to Figure 6 , the embodiment of the third embodiment is similar to the embodiment of the first embodiment. For details, please refer to the embodiment of the first embodiment, which will not be described in detail here. The difference between the two lies in the processing procedure of the step structure 14. The specific embodiment of the third embodiment for:

[0058] Process the outline of the frame of the mobile phone case 100 into a stepped structure 14. The step is set between the step of stamping the metal substrate 10 and the step of bending the stamped metal substrate 10 at a position close to the antenna groove 30, that is, this Processing as individual steps. In this mode, the mold processing is relatively simple and the cost is relatively low.

[0059] Examples of cell phone cases:

[0060] see Figure 1 to Figure 8 , the best embodiment of the mobile phone casing of the present invention is set forth below. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com