Single-excitation ultrasonic elliptical vibration micro-machining work platform

A technology of elliptical vibration and working platform, which is applied in the directions of worktable, fluid using vibration, manufacturing tools, etc., can solve the problems of ultrasonic machining resonance frequency drift, unstable processing quality, and reduced processing efficiency, so as to improve work reliability, Simple structure, stable vibration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

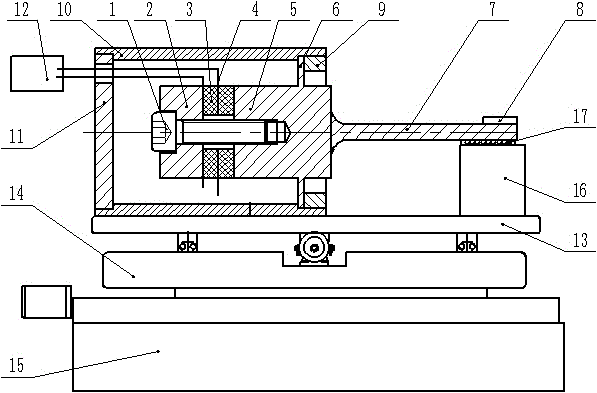

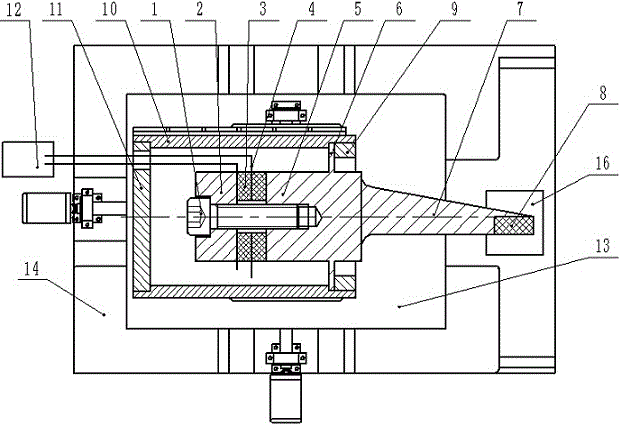

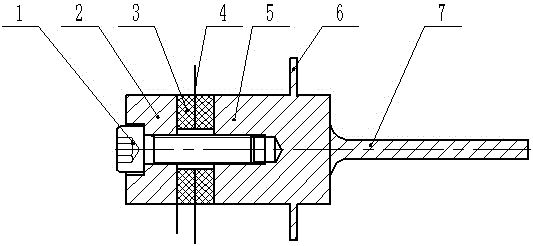

[0021] combine figure 1 , 2 , 3, and 4, the single-excitation ultrasonic elliptical vibration micromachining work platform includes a vibration isolation platform 15, a lateral mobile work platform 14 connected to the top of the vibration isolation platform 15 by bolts, and a horizontal mobile work platform 14 connected to the top of the lateral mobile work platform 14 by bolts. Longitudinal mobile working platform 13, shell unit, ultrasonic vibration transducer placed in the shell unit, ultrasonic power supply 12, elliptical vibration mode converter 7 and small working platform 8 arranged at the front end of elliptical vibration mode converter 7 . An auxiliary support 16 is arranged below the end of the elliptical vibration mode converter 7 , and a rolling support body 17 is arranged between the end of the elliptical vibration mode converter 7 and the auxiliary support 16 . The housing unit is connected above the longitudinally movable working platform 13 through bolts, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com