Method for scrubbing silk-screen printing and classification inspection conveyor belt

A conveyor belt and screen printing technology, which is applied in the field of crystalline silicon solar cell production, can solve problems such as the reduction of electrical performance parameters, affecting the quality of the cell, and the poor surface of the cell, so as to control the cleaning cycle, reduce equipment maintenance time, Effect of reducing surface defect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

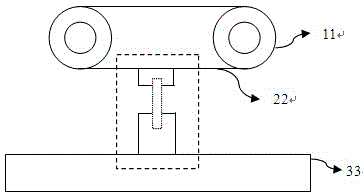

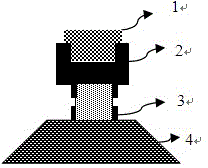

[0010] Attached below figure 1 and 2 The technical scheme of the present invention is described in further detail.

[0011] In this specific embodiment, a screen printing and sorting transmission belt scrubbing method, the device includes four parts: a base, a screw rod, a sponge block and a sponge slot, and the sponge block and the slot pass through the screw rod and the base Installed on the machine table and directly under the belt, and the scrubbing process is realized through the friction sponge driven by the belt itself; the length and width dimensions inside the sponge slot match the corresponding size of the sponge block, and the height of the slot is lower than the sponge The block height is 1cm; the screw rod is a lifting screw rod, and the control range of the lifting height is 25cm. Through this specific embodiment, the screen printing and sorting conveying belt scrubbing device reduces the surface defect ratio of cells caused by belt contamination, effectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com