Full-automatic few-leaf-spring long cone rolling production line

A leaf spring, fully automatic technology, applied in the field of fully automatic few-leaf spring long cone rolling production line, can solve the problems of complex rolling process and large change of steel plate section, and achieve short pressurization process, fast pressurization process and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

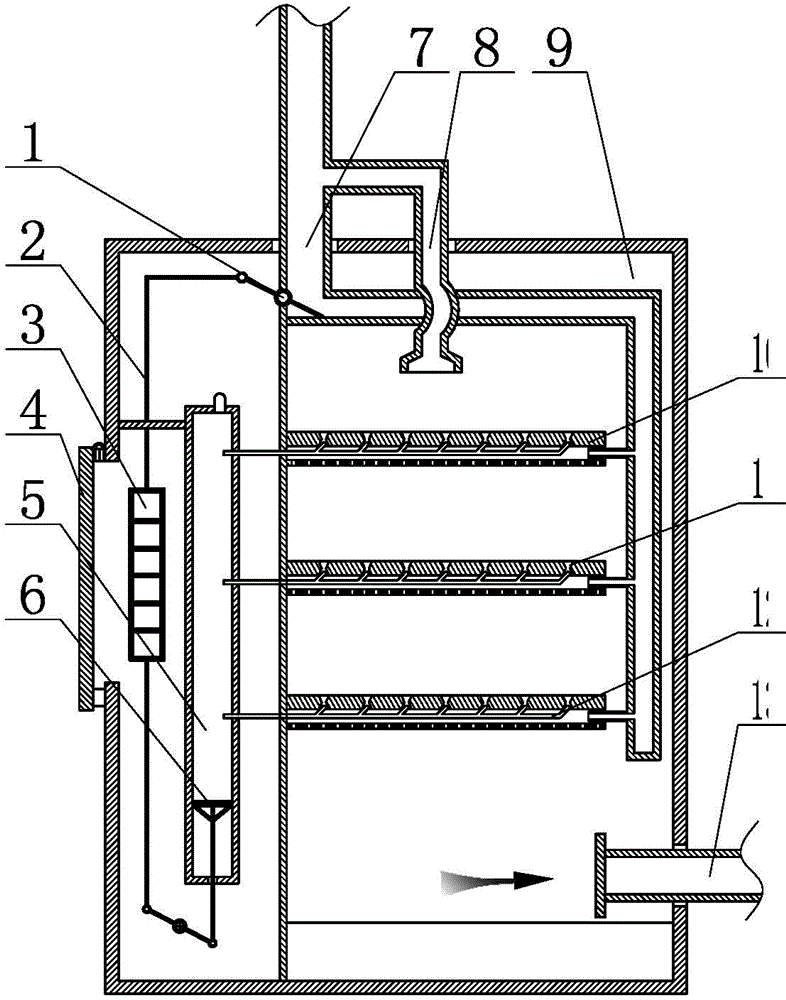

[0060] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

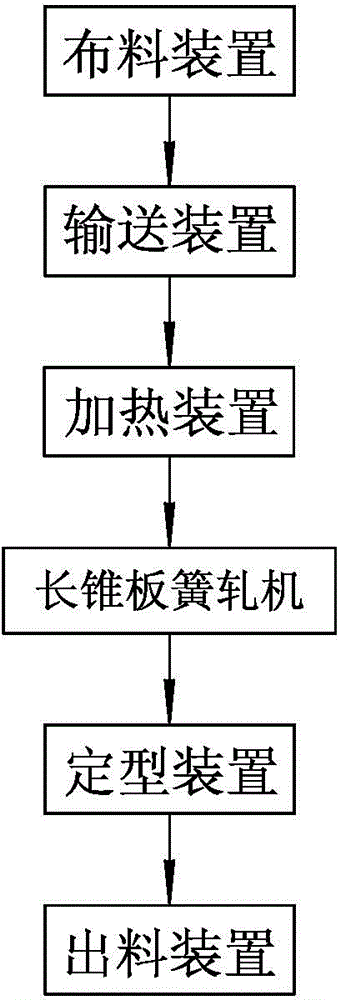

[0061] Such as figure 1 As shown, the full-automatic long-cone rolling production line for few-piece springs is characterized in that: the full-automatic long-cone rolling production line for few-piece springs is successively equipped with automatic distributing machine, heating furnace, descaling equipment, automatic loading and unloading machine, long Conical leaf spring rolling mill, straightening machine and shaping equipment, each production equipment is connected by conveying device.

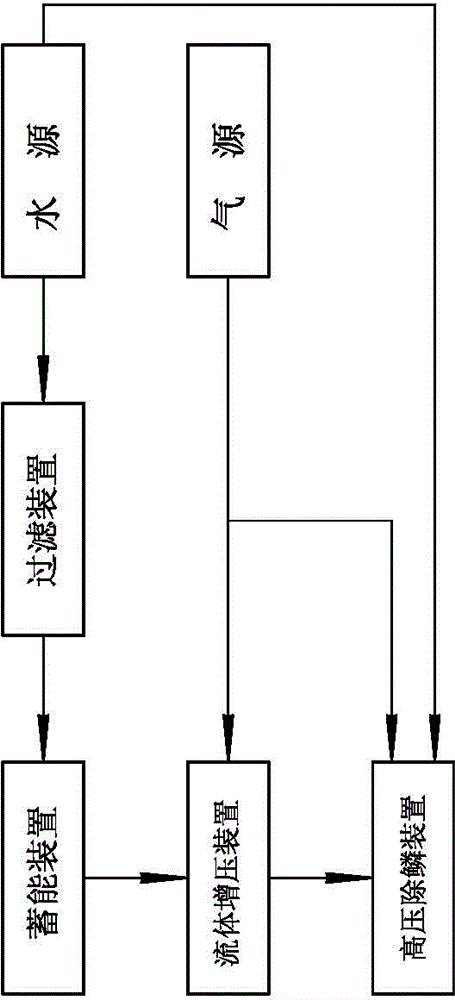

[0062] Such as figure 2 As shown, the descaling equipment includes a filter device, an energy storage device, a fluid booster device and a high-pressure descaling device. The filter device is connected to the water source through a pipeline; the energy storage device is connected to the filter device through a pipeline; The pipeline is respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com