Simple tool setting device for numerical controlled lathe and using method

A technology of a numerical control lathe and a tool setting device is applied in the field of mechanical processing, which can solve problems such as tool setting, and achieve the effects of low production cost, simple structure and satisfying processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

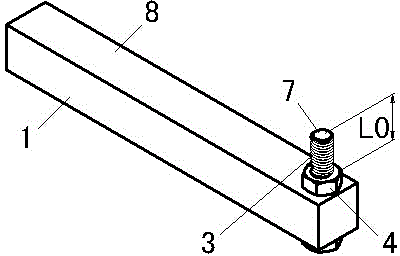

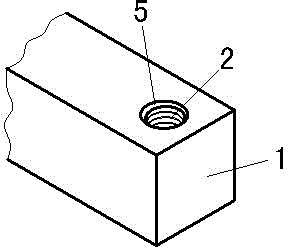

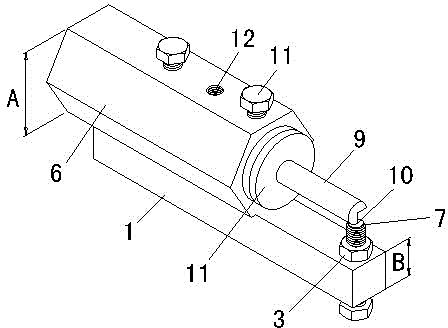

[0020] A tool setting device for a CNC lathe, such as figure 1 and figure 2 As shown, it includes a tool setting block 1, a threaded hole 2 is provided on the tool setting block 1, a tool setting screw 3 is provided in the threaded hole 2, and a lock nut 4 is provided on the tool setting screw 3. The shape of the tool setting block 1 is a rectangular cylinder, and the threaded hole 2 is located on the side of one end of the rectangular cylinder. The threaded hole 2 is a through hole, and chamfers 5 are provided at both ends. The length L of the screw part of the tool setting screw 3 is greater than 1 / 2 of the thickness A of the CNC lathe tool holder 6 plus the thickness B of the tool setting block 1; the end face of the tool setting screw 3 screw is the tool setting reference plane 7 of the turning tool tip.

[0021] The method of using the aforementioned device, the method is as image 3 Shown, carry out tool setting according to the following steps:

[0022] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com