Self-adaptive dead zone inverse model generating device of visual servo mechanical arm system

A technology of visual servo and generating device, which is applied in manipulators, program-controlled manipulators, manufacturing tools, etc. It can solve the problems of control performance degradation, instability, gear use time and frequency loss, etc., and achieves reduction of complicated workload and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

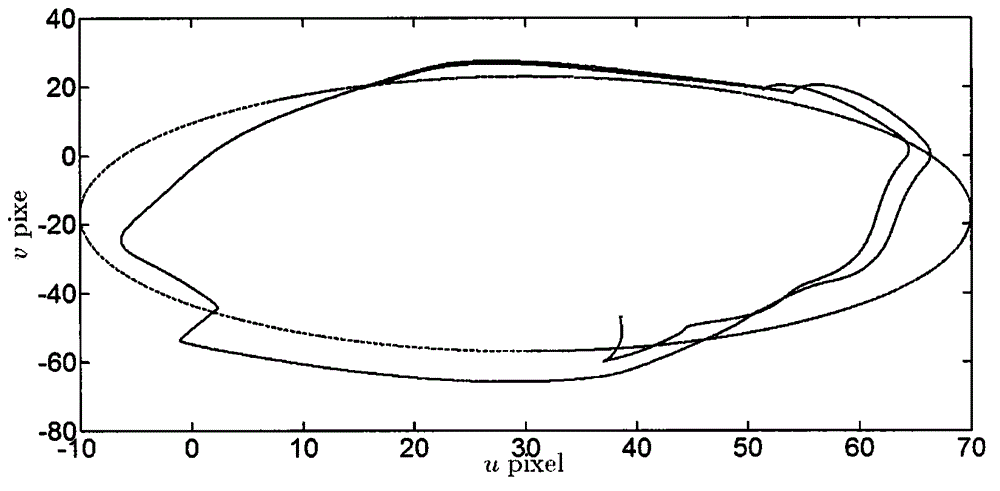

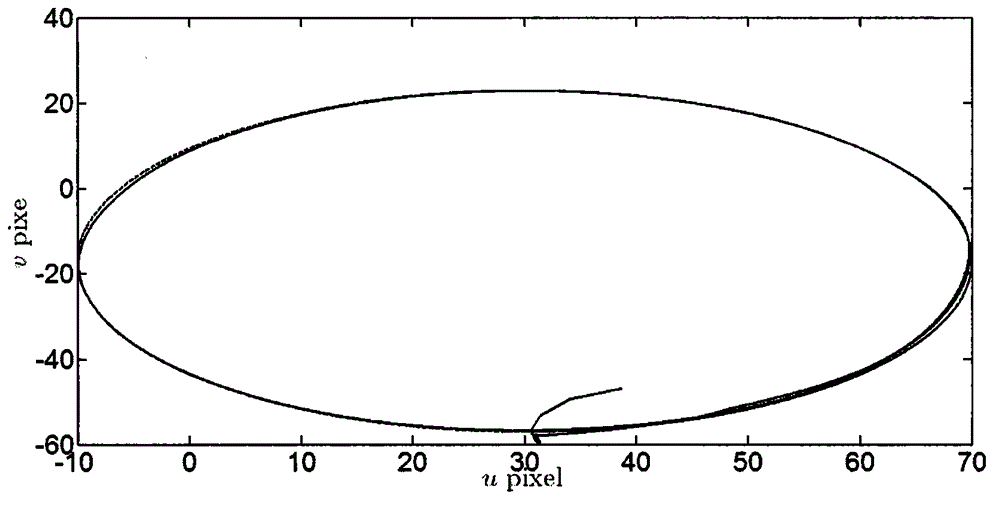

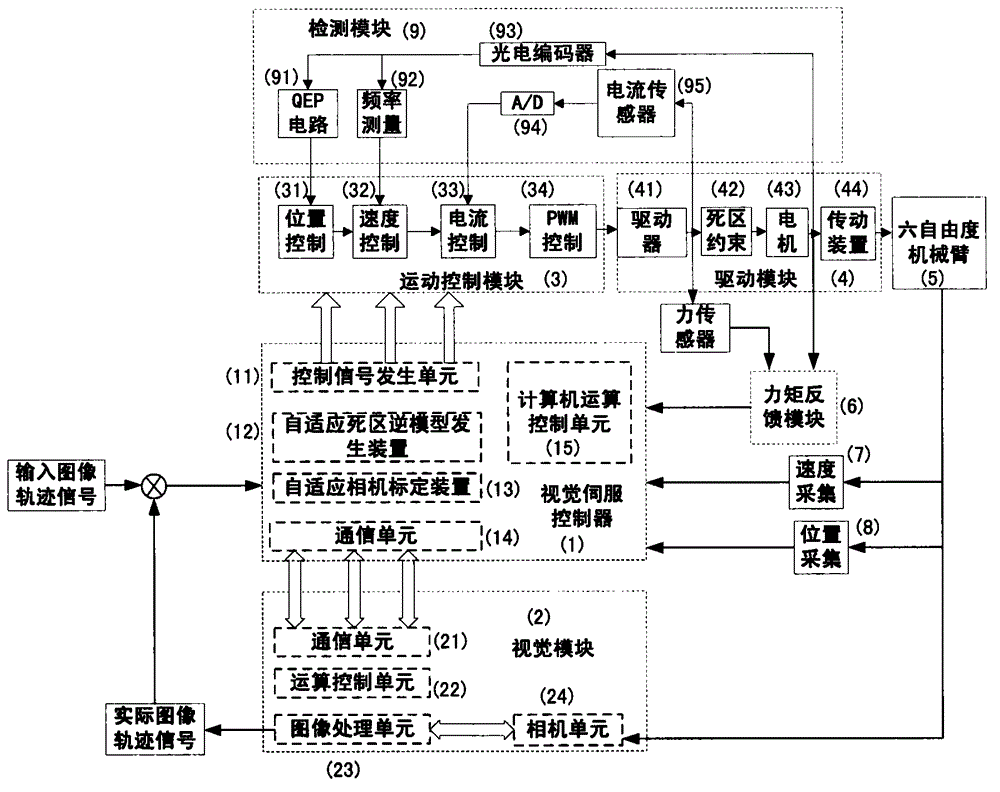

[0030] The invention relates to a dead zone inverse model generating device of a visual servo manipulator control system, which uses the designed adaptive law to estimate the parameters of the dead zone nonlinear constraint model online, and then constructs the corresponding dead zone inverse model, which can effectively The visual servo controller controls the manipulator to make the end feature points gradually track the desired image trajectory on the image plane under the condition that the input signal is eliminated, so as to achieve high image tracking accuracy. The dead zone inverse model generation device of the visual servo manipulator control system designed by the present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

[0031] figure 1 It is the overall block diagram of the visual servo manipulator system with dead zone nonlinear constraints. exist figure 1 The purpose of designing the visual servo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com