Simulation method for improving thickness uniformity of roll coating film of bolt fastener

A bolt fastener with uniform thickness technology, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve problems such as difficult to comprehensively investigate and study the process of barrel plating, to reduce verification cycle, The effect of reducing the troublesome workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] The simulation method of the invention can be applied to the cadmium barrel plating process of fasteners, and is also applicable to other barrel plating processes. The specific implementation manner of the present invention will be described below with the cadmium barrel plating process.

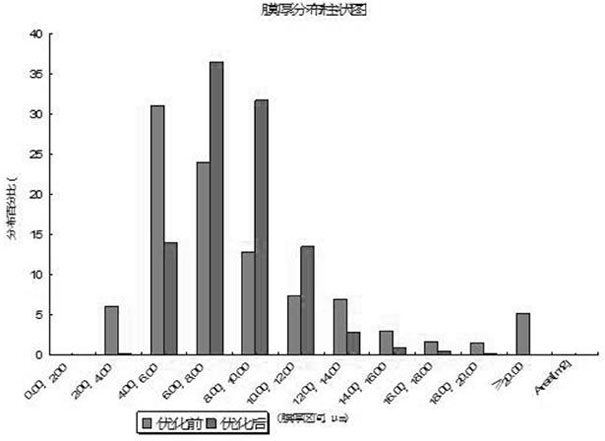

[0021] A simulation method for improving the thickness uniformity of the barrel coating film of a bolt fastener, comprising the following steps:

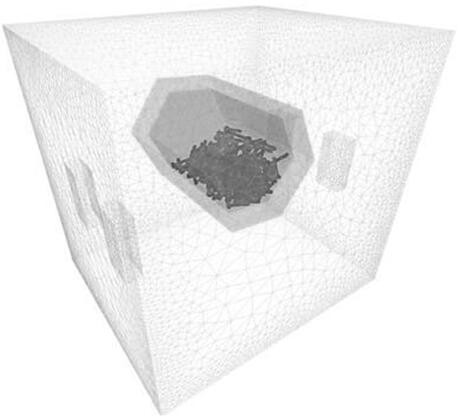

[0022] (1) Modeling: Use 3D drawing software to establish 3D space models of parts and electroplating production lines, such as figure 1 As shown, the digital model database of the electroplating production line is established, and the digital model database of the electroplating production line includes tank grid data, drum grid data, grid and polarization data of the anode, data of the current efficiency of the electroplating solution changing with the current density, Tafel curve and other data;

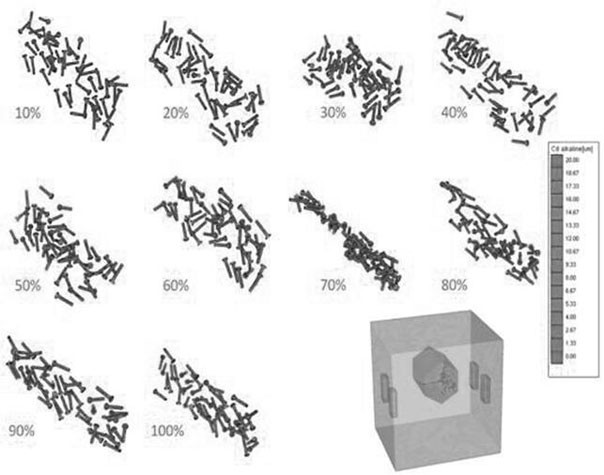

[0023] (2) Calculate the spatial posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com