Vibration-reduction light fodder chopper

A guillotine, portable technology, applied in the field of material cutting devices, can solve the problems of not considering the reduction of cutting vibration, the complexity of the guillotine, etc., and achieve the effect of improving cutting efficiency, convenient use, and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

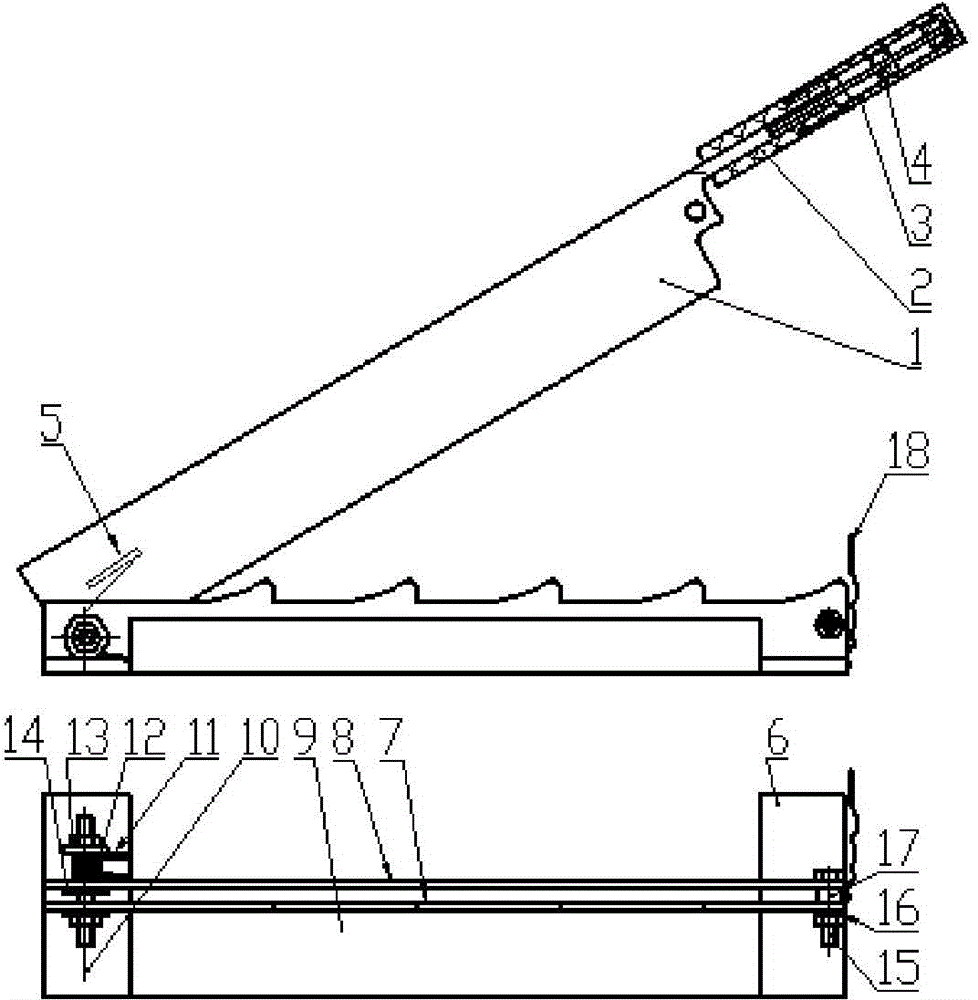

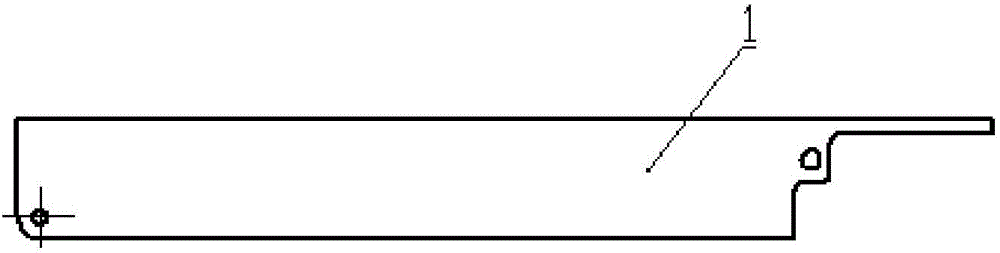

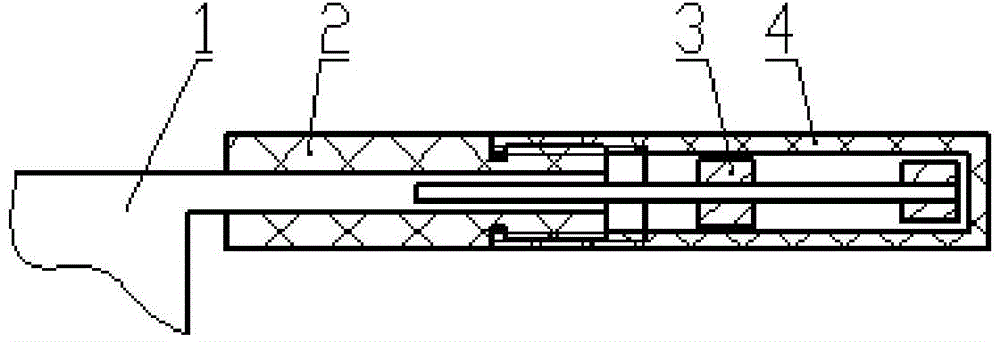

[0016] Such as figure 1 As shown, a lightweight guillotine with vibration reduction consists of a knife body 1, a handle body 2, a dynamic shock absorber 3, a handle cover 4, a slide plate 5, a bottom plate 6, a feed knife seat 7, a discharge knife seat 8, and a feed table 9 , Knife shaft 10, torsion spring 11, flat washer 12, nut 13, adjusting piece 14, locking system 15, bolt 16, elastic washer 17, sleeve 18 composition. Such as figure 2 As shown, the cutter body 1 is fixedly connected with the handle body 2, the cutter body 1 is 250-400mm long, 50-100mm wide, and 3-6mm thick, and a shaft hole is set at the tip of the cutter body 1, The diameter of the shaft hole is 6-10mm, the tip of the tool is processed into a circular arc shape, and a rectangular gap is processed at the root of the tool body 1, which is in contact with the bolt 16, so as to control the minimum height of the downward movement of the tool body. The material of the tool body 1 is 65 Manganese steel, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com