A method for manufacturing a high-gloss D-pillar decorative panel

A production method and column decoration technology are applied in the field of automotive exterior parts, which can solve the problems of failing to meet high-gloss and high-standard requirements, increasing pretreatment, and complicated painting processes, shortening delivery time, reducing environmental pollution, and reducing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

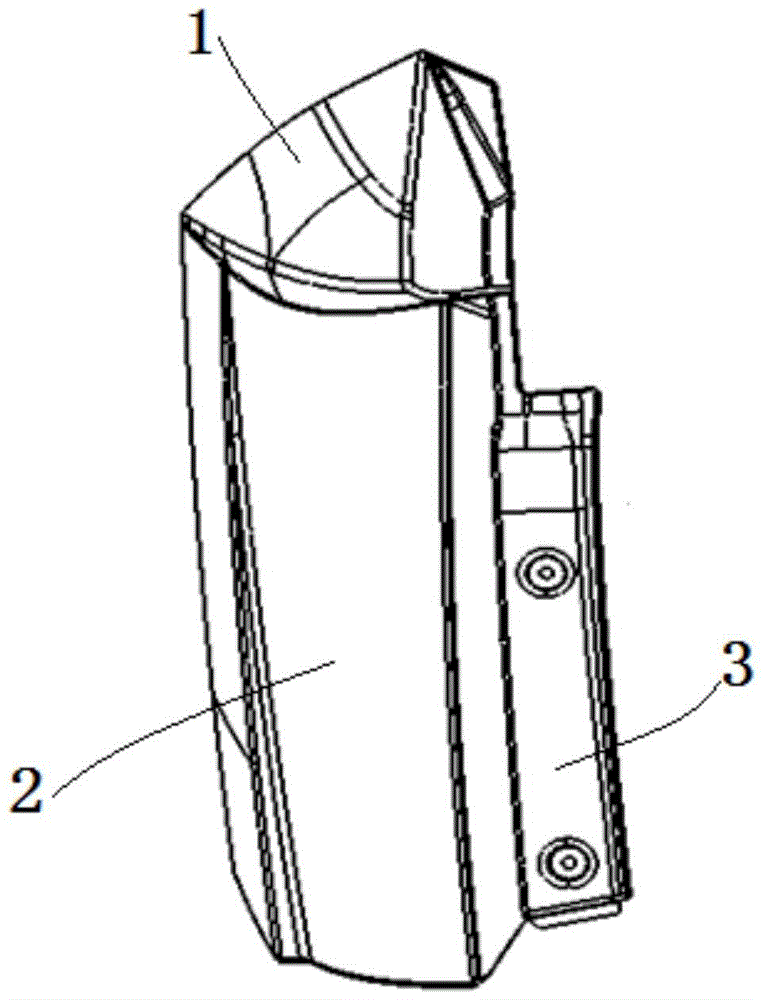

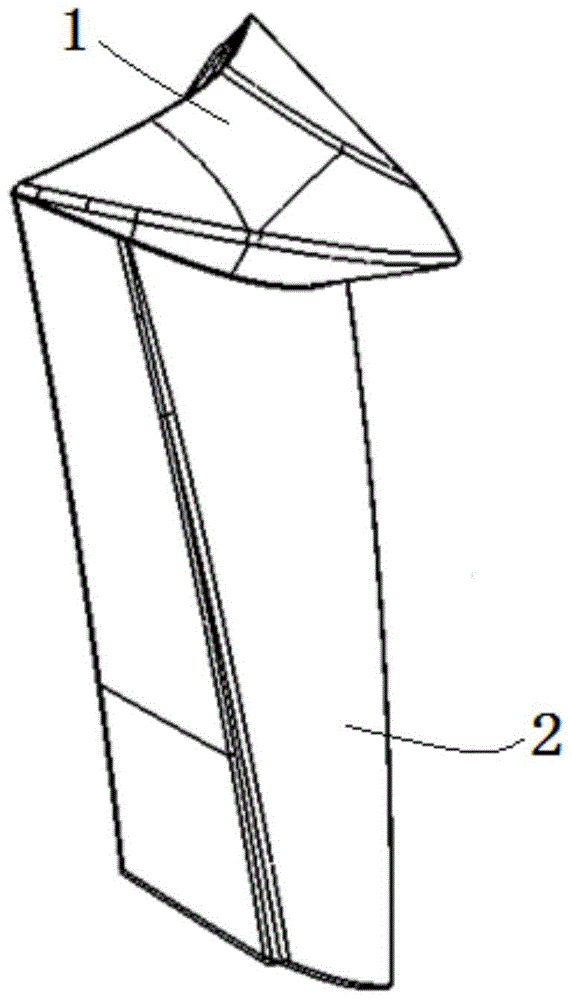

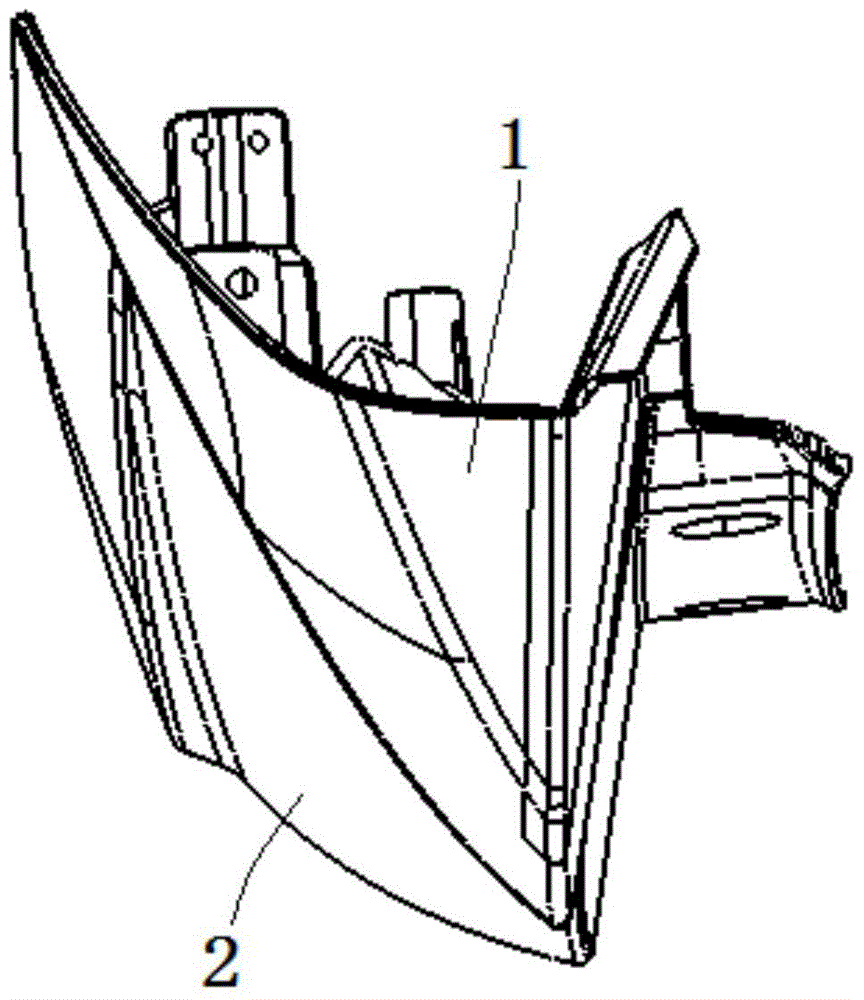

[0024] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

[0025] In the manufacturing method of the high-gloss D-pillar decorative panel, the D-pillar decorative panel is made by a high-gloss seamless injection molding process. The high-gloss seamless injection molding process uses 180°C superheated water to rapidly heat up the surface of the mold (the high-gloss surface needs to be mirror-polished), so that the surface temperature of the molding cavity reaches above the glass transition temperature (Tg–Glass Transition Temperature) of the resin plastic, and then Started injection molding. When the mold cavity filling process is completed, the treated water is used as the cooling medium to make the surface temperature of the mold drop rapidly; thereby changing the surface characteristics of the plastic product, eliminating the weld lines, weld mar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com