A method for continuously preparing ishikawa fluorinating agent and a reaction device for realizing the method

A fluorinating agent and two-stage injection technology, which is applied in the direction of condensation/addition reaction to prepare amino compounds, organic chemistry, etc., can solve the problems of local heat release, heat removal, long reaction time, etc., and achieve production efficiency High, efficiency-enhancing, fast-response effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

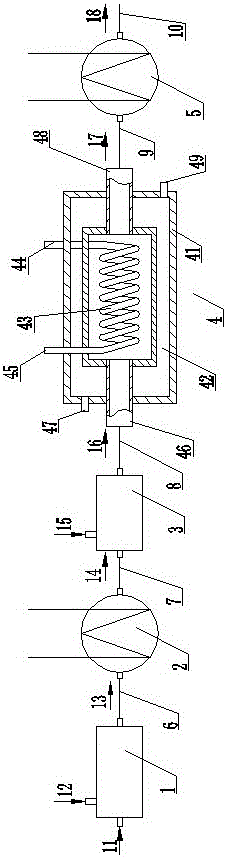

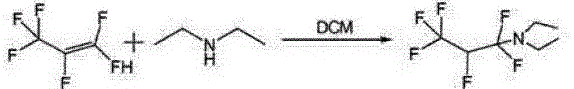

[0023] Reaction device for realizing the method of continuous preparation of Ishikawa fluorinating agent, such as figure 1 As shown, it includes a primary jet mixer 1, a primary cooler 2, a secondary jet mixer 3, a static mixer 4 and a secondary cooler 5 arranged sequentially from front to back according to the process route. The first-stage jet mixer 1 and the second-stage jet mixer 3 have the same structure and are all existing products. For example, products such as SX / SK / SV / SL that can be produced by Qidong Mixer Factory Co., Ltd. can be adopted, and its structure is not described here. To repeat, the first-stage jet mixer 1 and the second-stage jet mixer 3 are each provided with two liquid inlets and one liquid outlet. The primary cooler 2 and the secondary cooler 5 have the same structure and are existing products. The primary cooler 2 and the secondary cooler 5 are each provided with a liquid inlet and a liquid outlet. heat exchangers, plate heat exchangers and other f...

Embodiment 2

[0026] Feed dichloromethane into the primary jet mixer with a flow rate of 600g / h, and feed diethylamine with a flow rate of 65g / h simultaneously, and dichloromethane and diethylamine are mixed in the primary jet mixer to form a mixed solution, After the mixed liquid is sprayed from the primary jet mixer, it directly enters the primary cooler and is rapidly cooled to below -20°C to form a cooled mixed liquid; then, the cooled mixed liquid directly enters the secondary jet mixer, and at the same time, it is cooled at a rate of 160g / h The flow rate conveys hexafluoropropylene to the secondary jet mixer, thereby forming a premixed liquid of cooling mixed liquid and hexafluoropropylene in the secondary jet mixer; the premixed liquid is sprayed from the secondary jet mixer and directly enters the static mixer, pre The mixed liquid is subjected to strong mixing and continuous reaction in the static mixer, the heat generated by the reaction is quickly removed by the cooling device in ...

Embodiment 3

[0028] Feed dichloromethane into the primary jet mixer with a flow rate of 700g / h, and feed diethylamine with a flow rate of 85g / h simultaneously, and dichloromethane and diethylamine are mixed in the primary jet mixer to form a mixed solution, After the mixed liquid is sprayed from the primary jet mixer, it directly enters the primary cooler and is rapidly cooled to below -25°C to form a cooled mixed liquid; then, the cooled mixed liquid directly enters the secondary jet mixer, and at the same time, it is cooled at a rate of 165g / h The flow rate sends hexafluoropropylene to the secondary jet mixer, thereby forming a premixed liquid of cooling mixed liquid and hexafluoropropylene in the secondary jet mixer; the premixed liquid is sprayed from the secondary jet mixer and directly enters the static mixer. The mixed liquid is strongly mixed and continuously reacted in the static mixer, the heat generated by the reaction is quickly removed by the cooling device in the static mixer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com