Patents

Literature

32results about How to "Mix vigorously" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

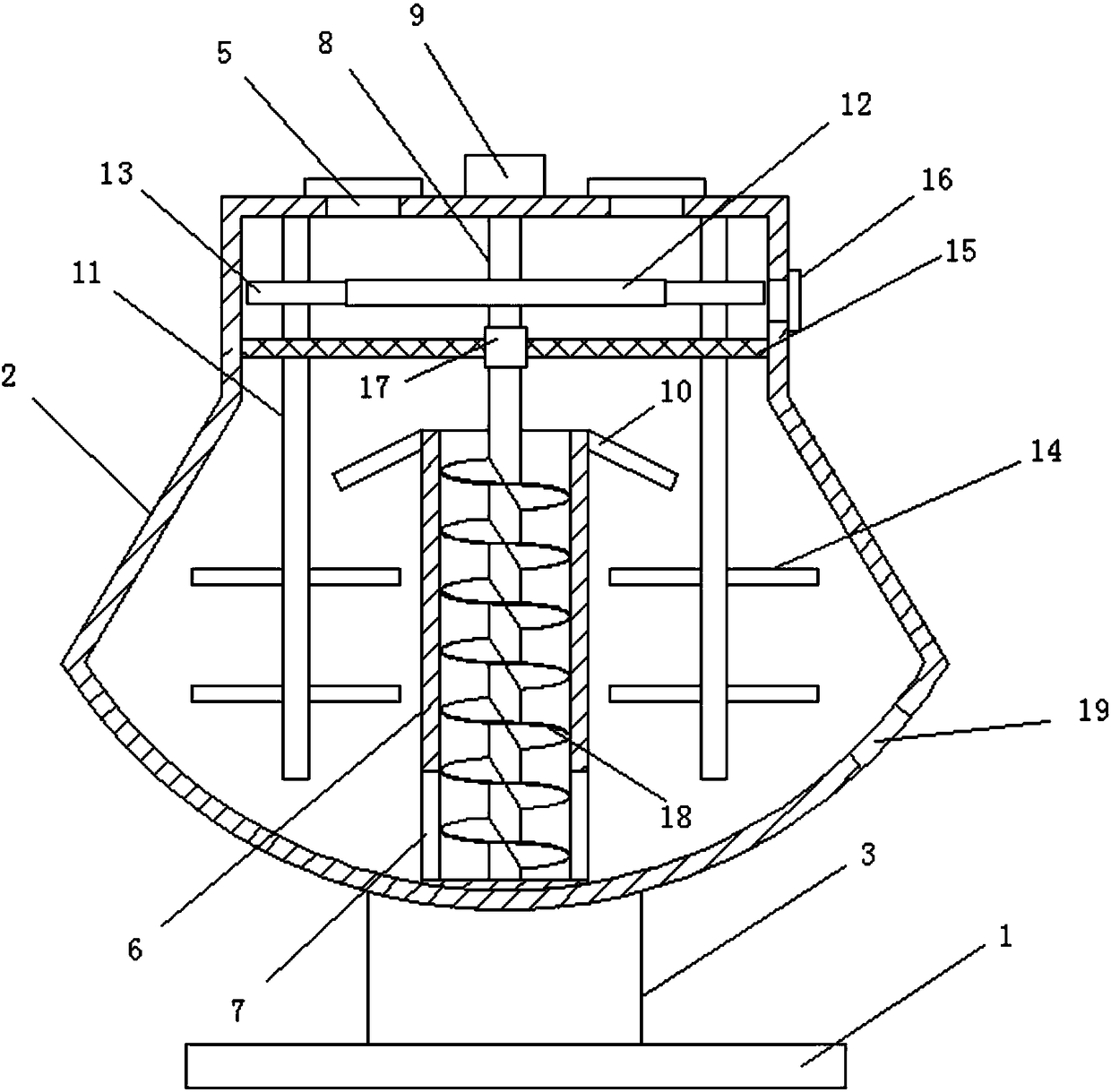

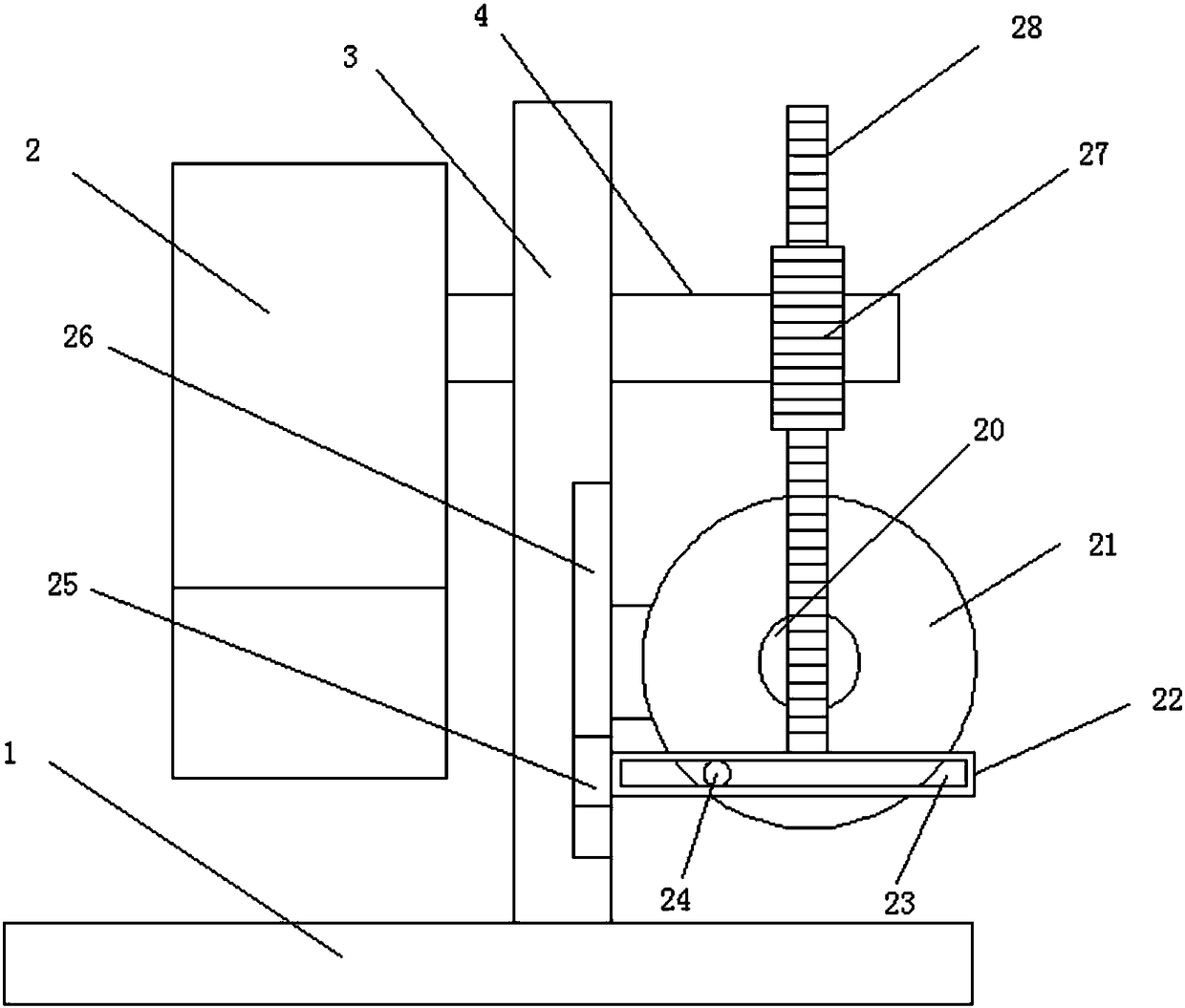

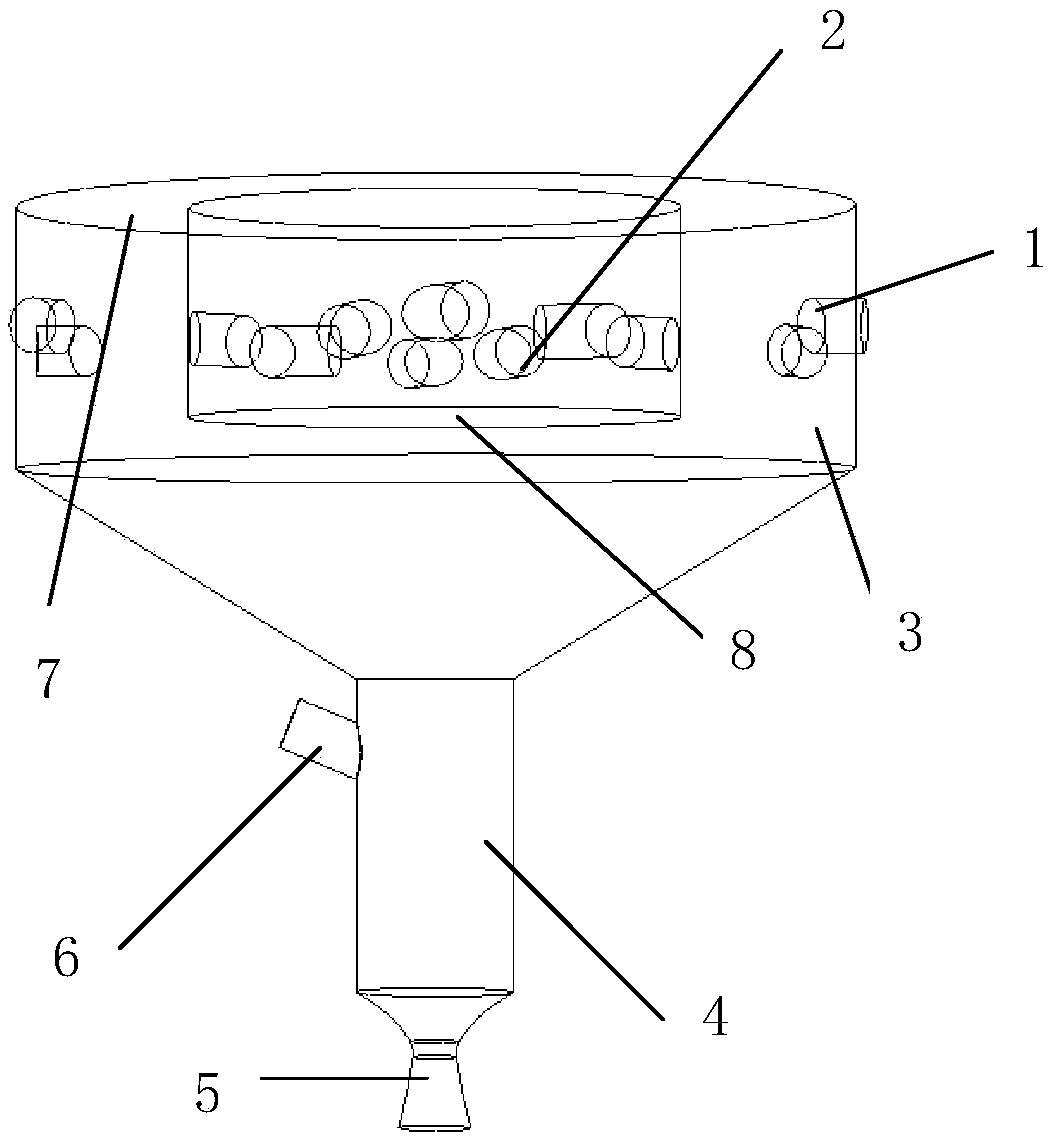

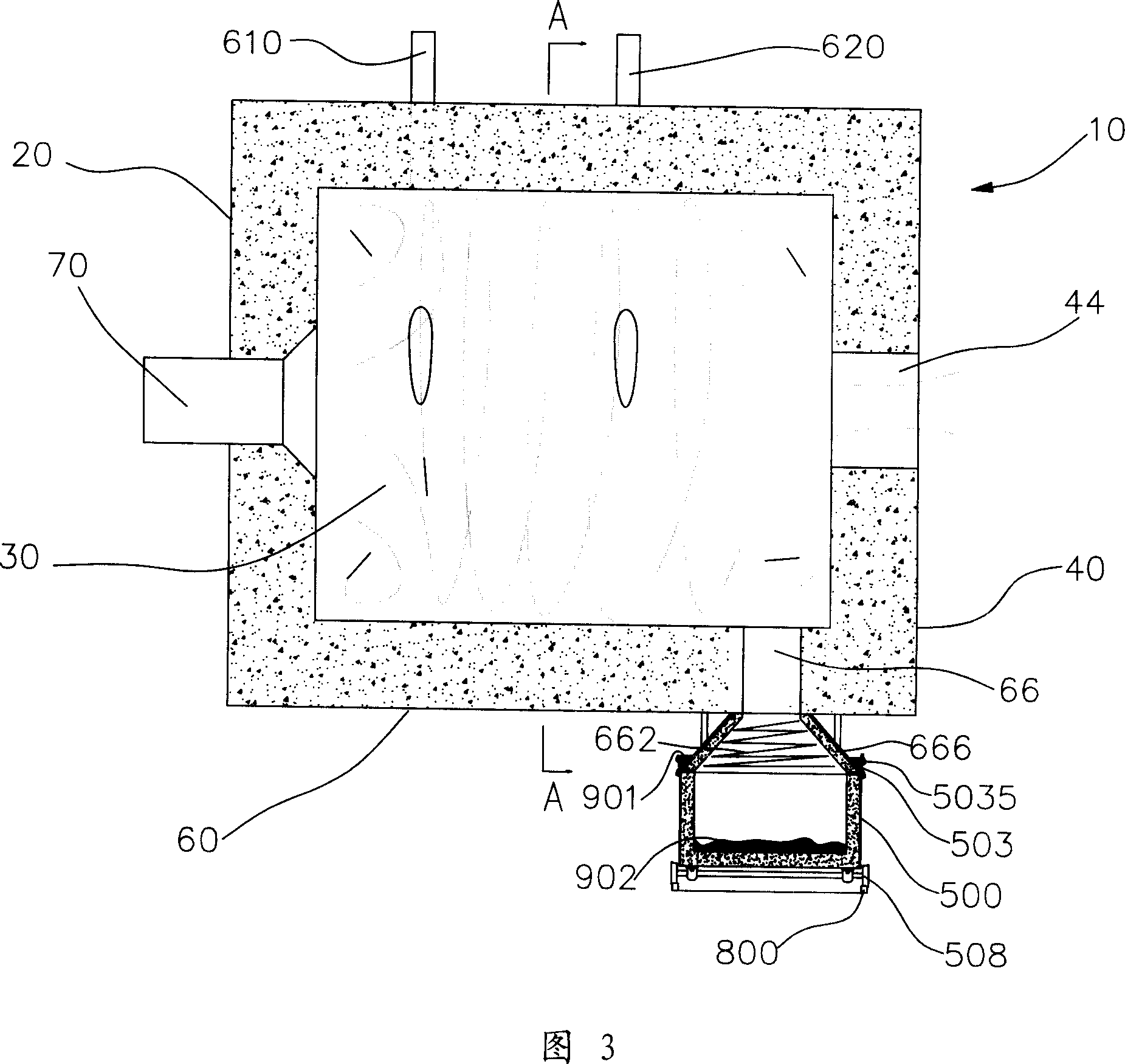

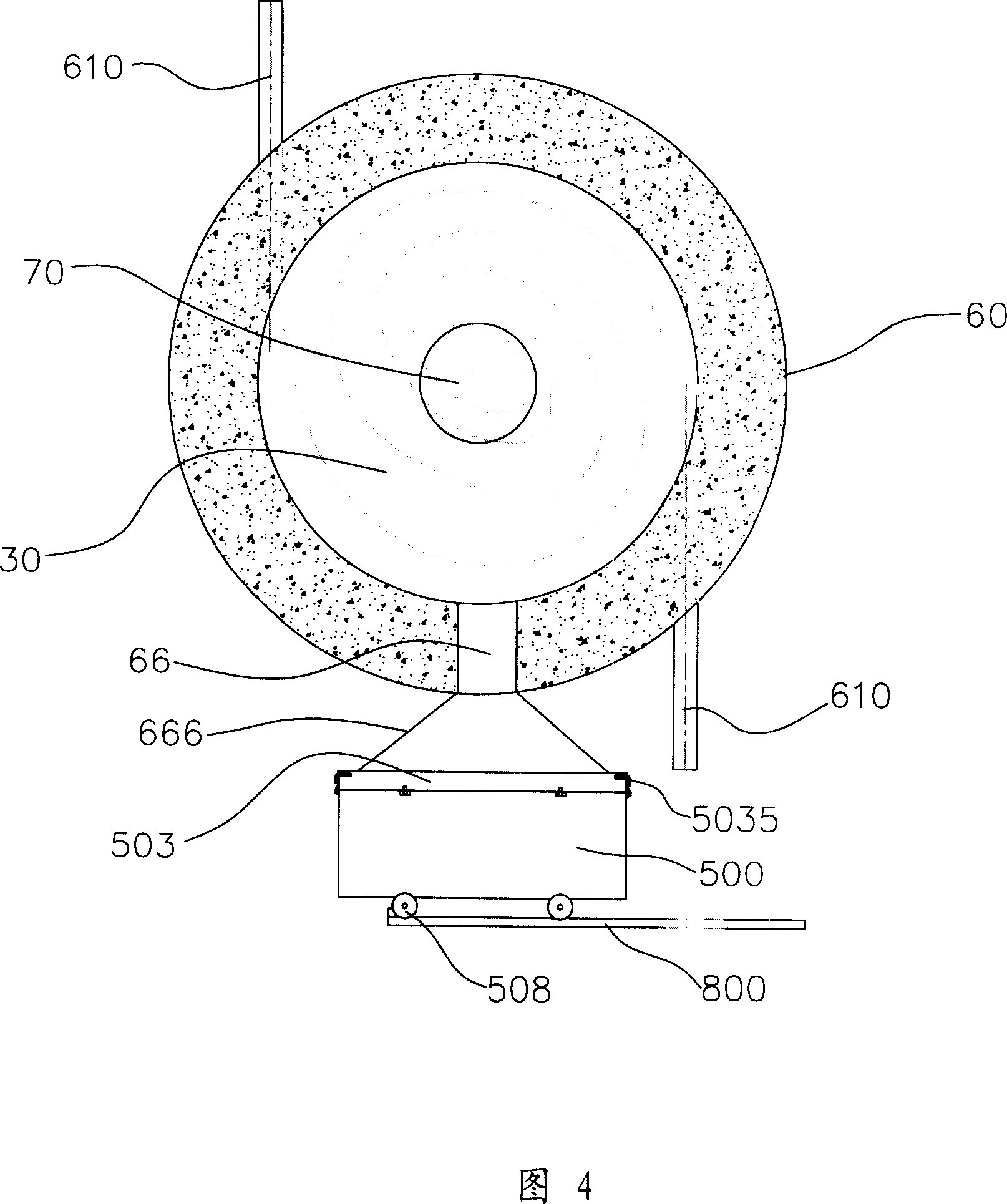

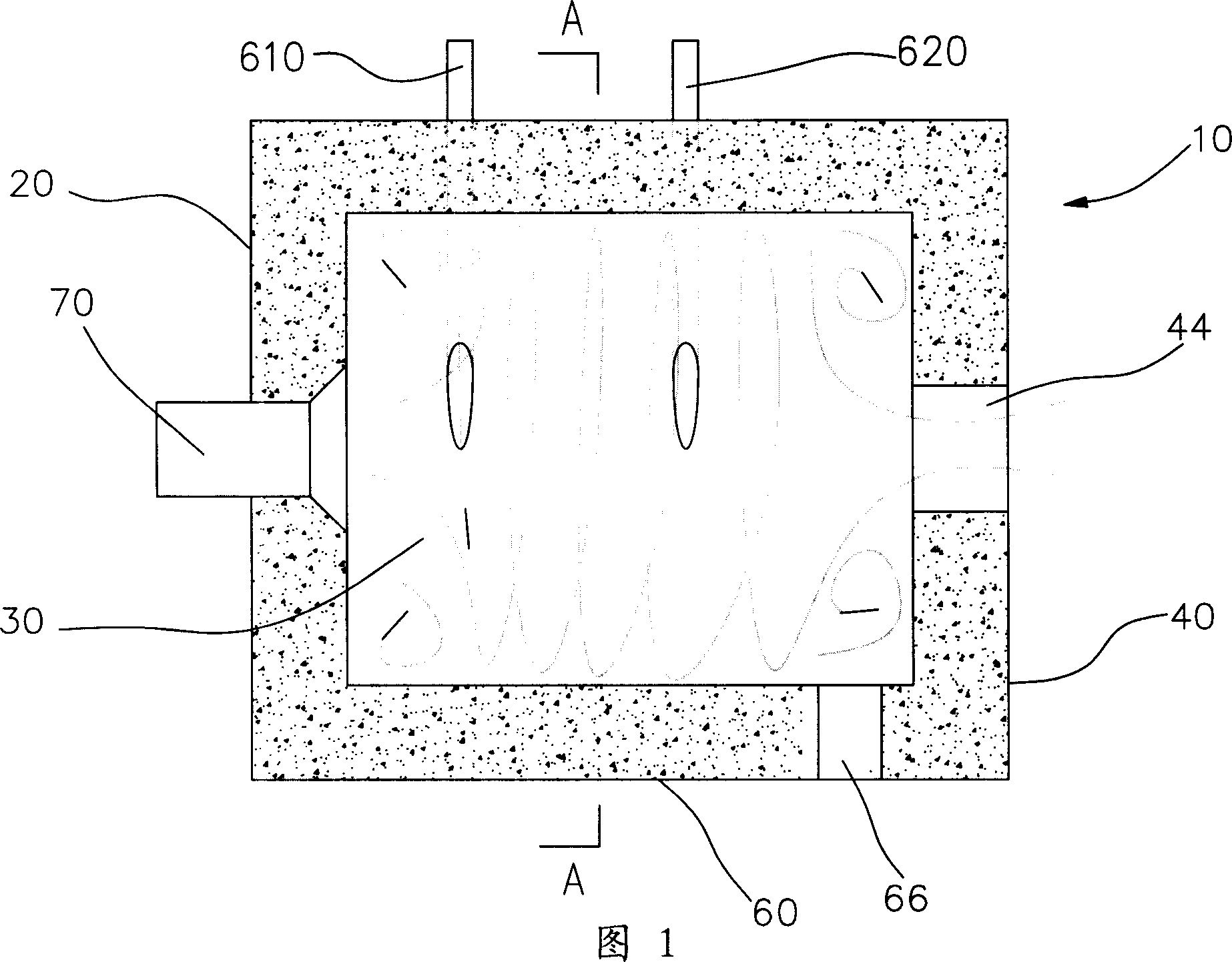

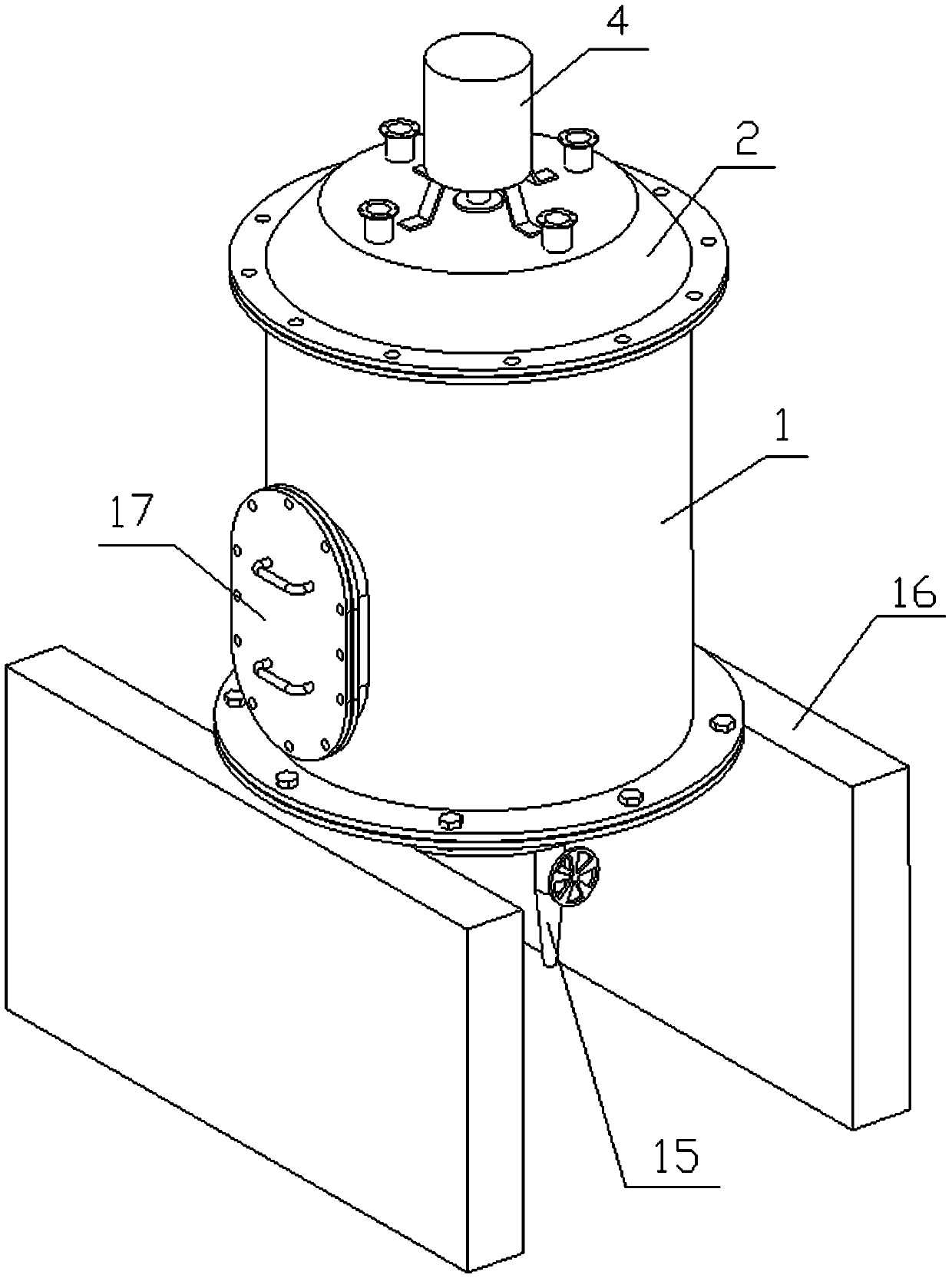

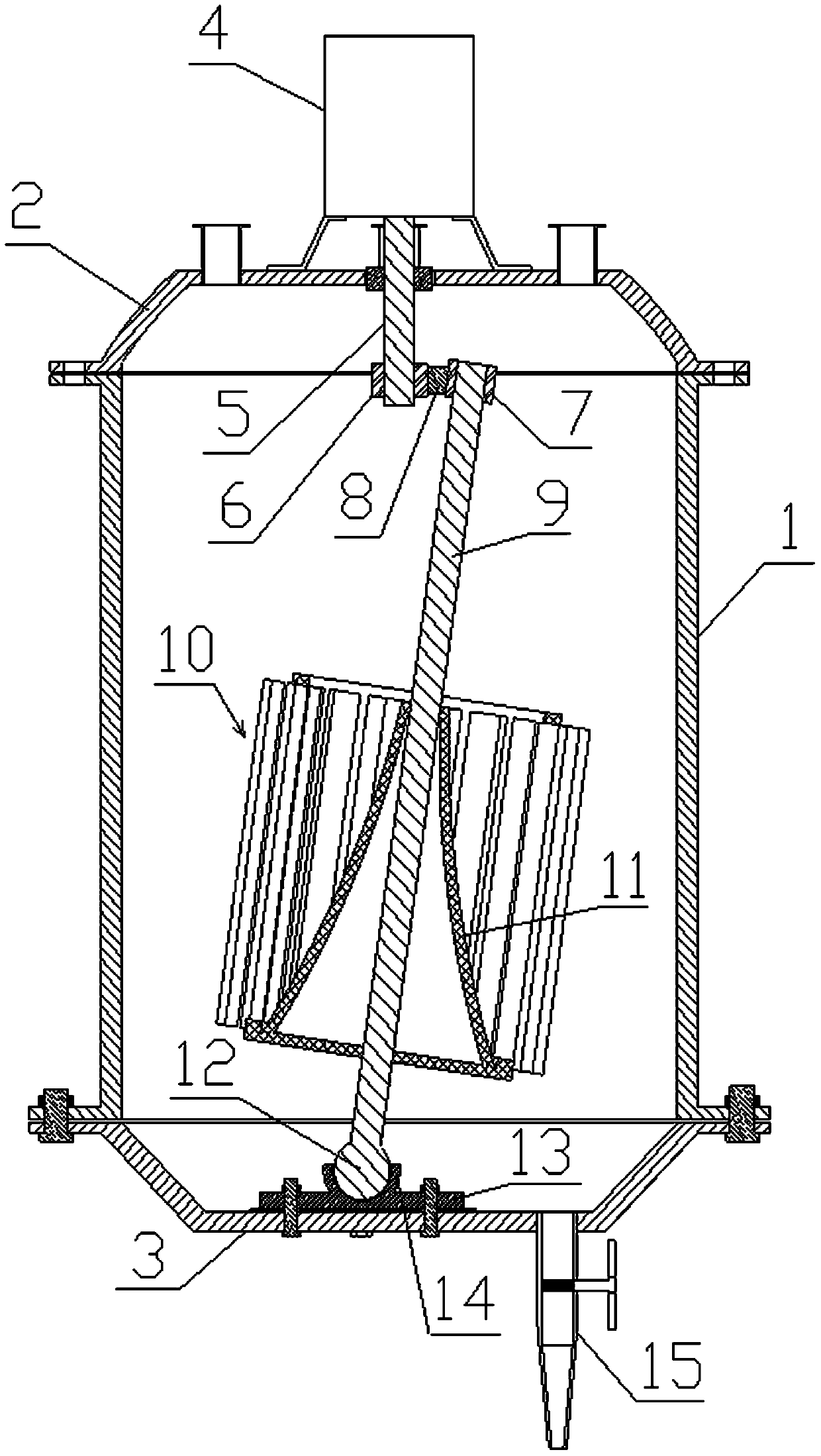

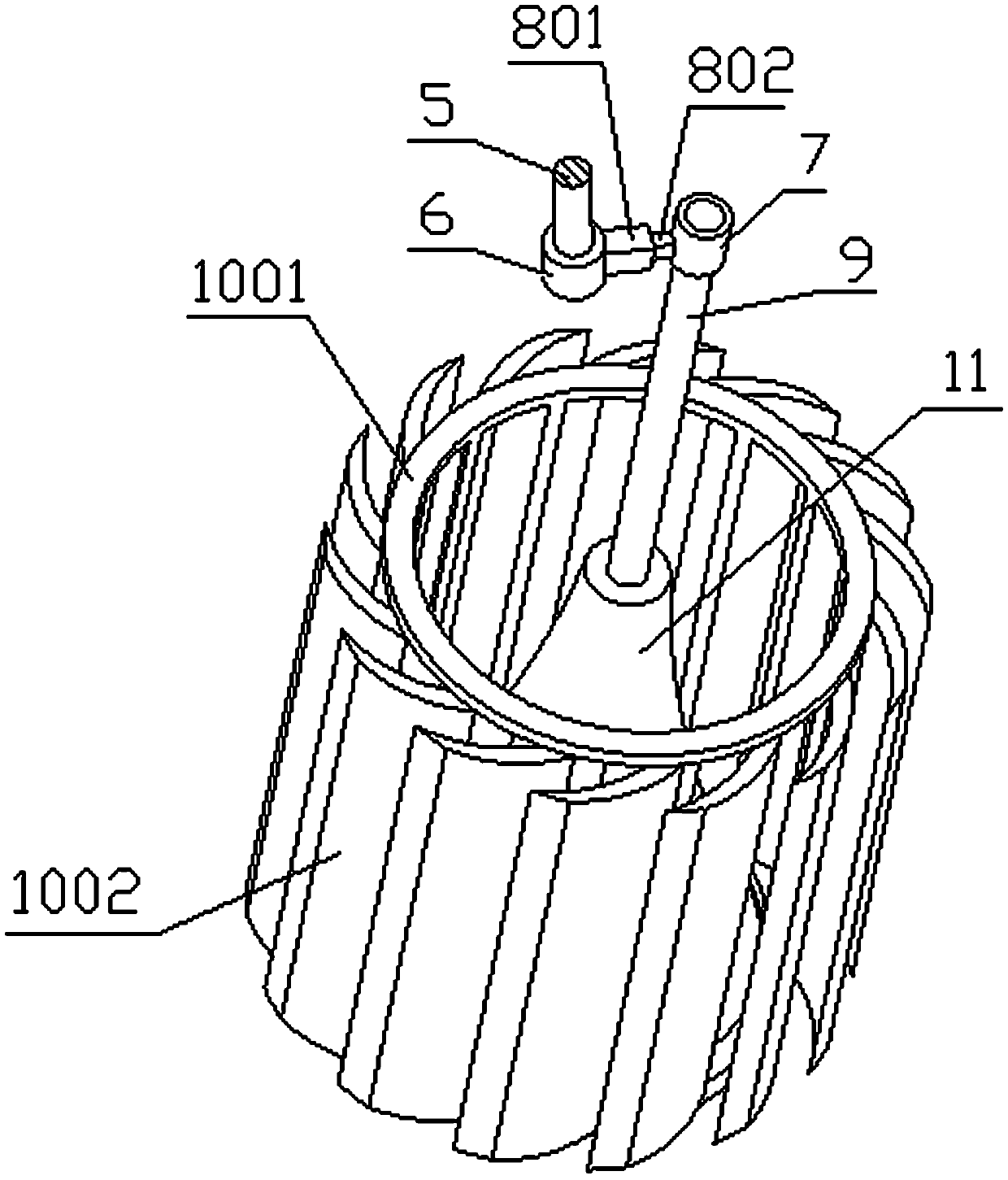

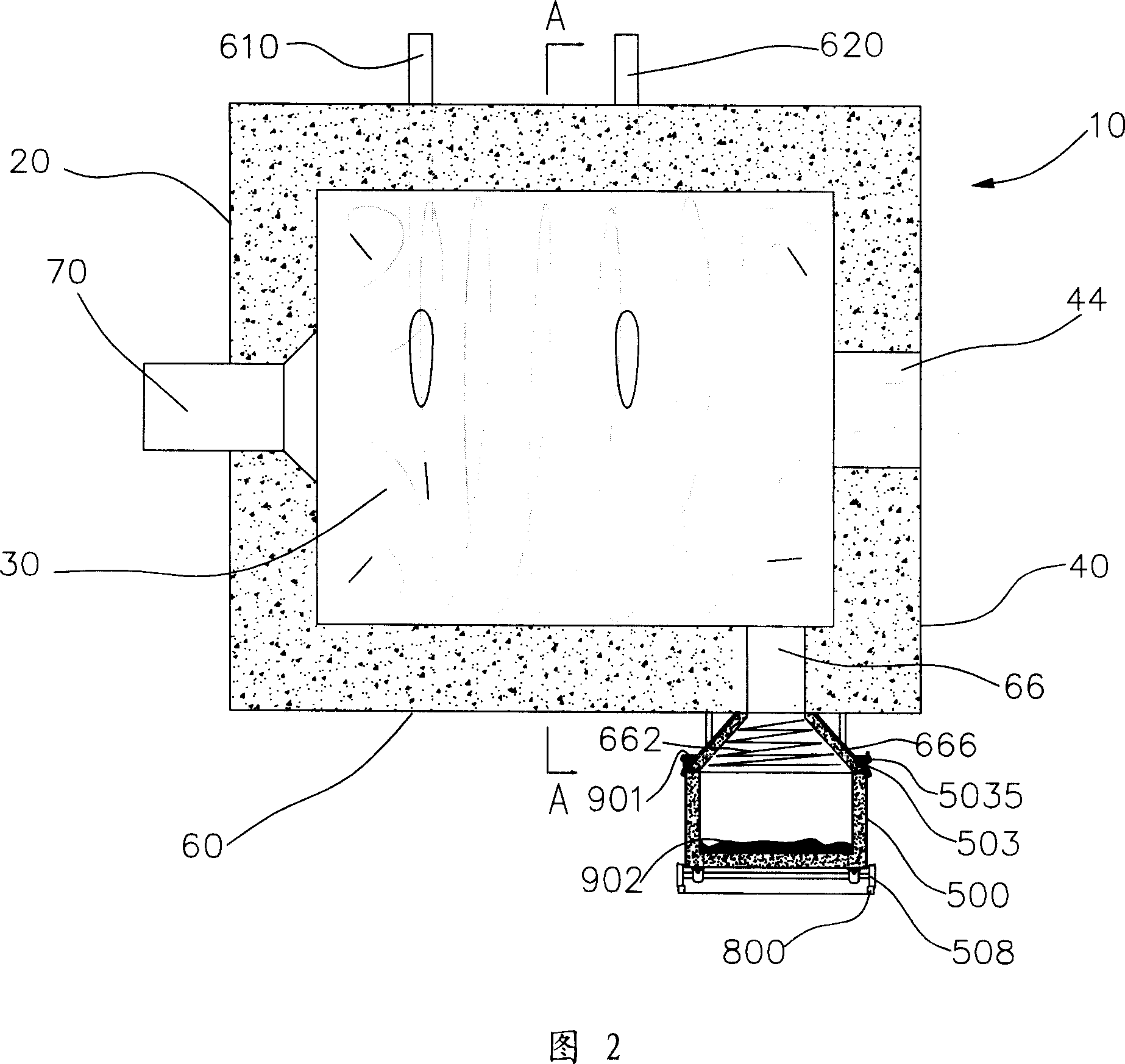

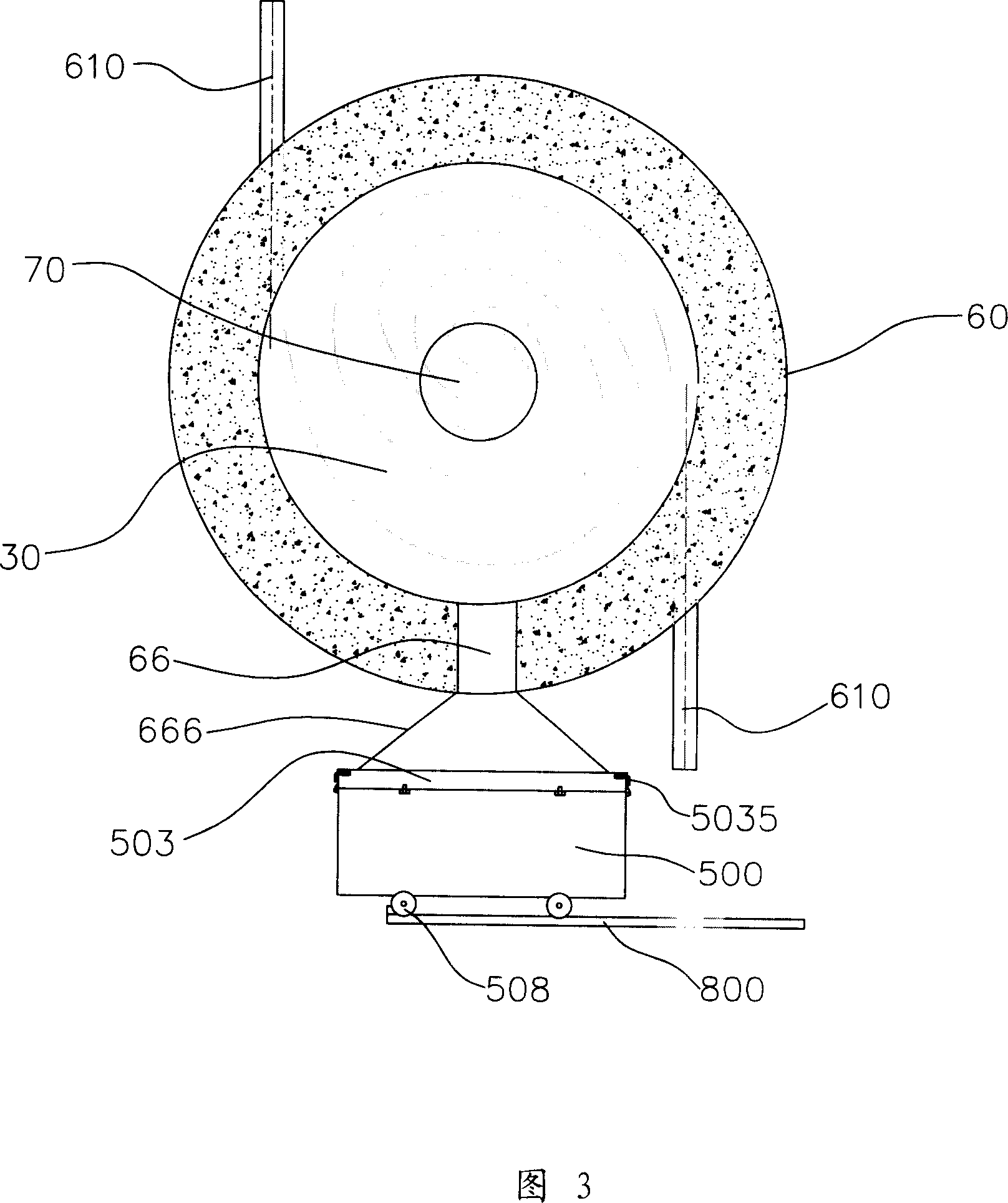

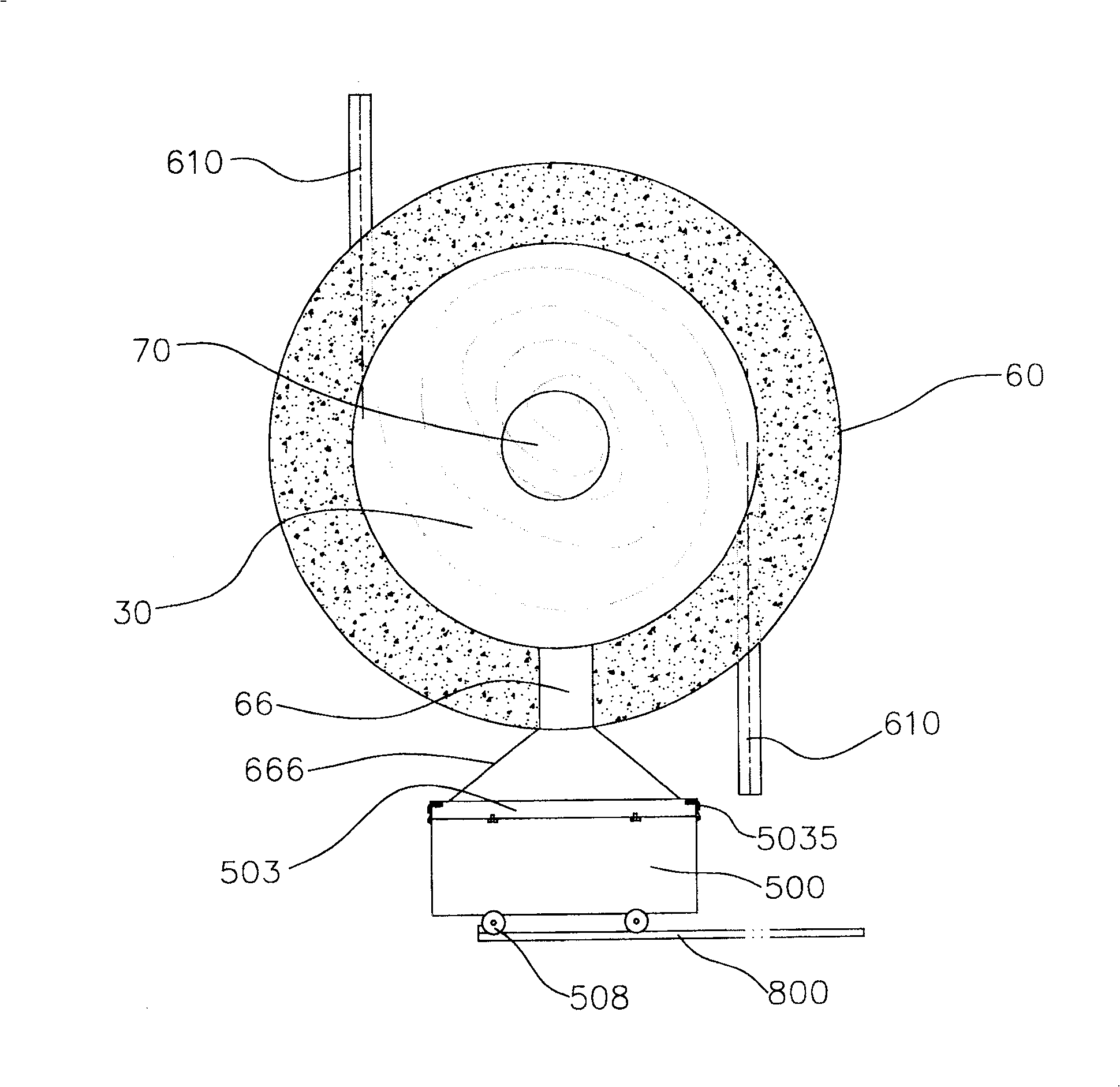

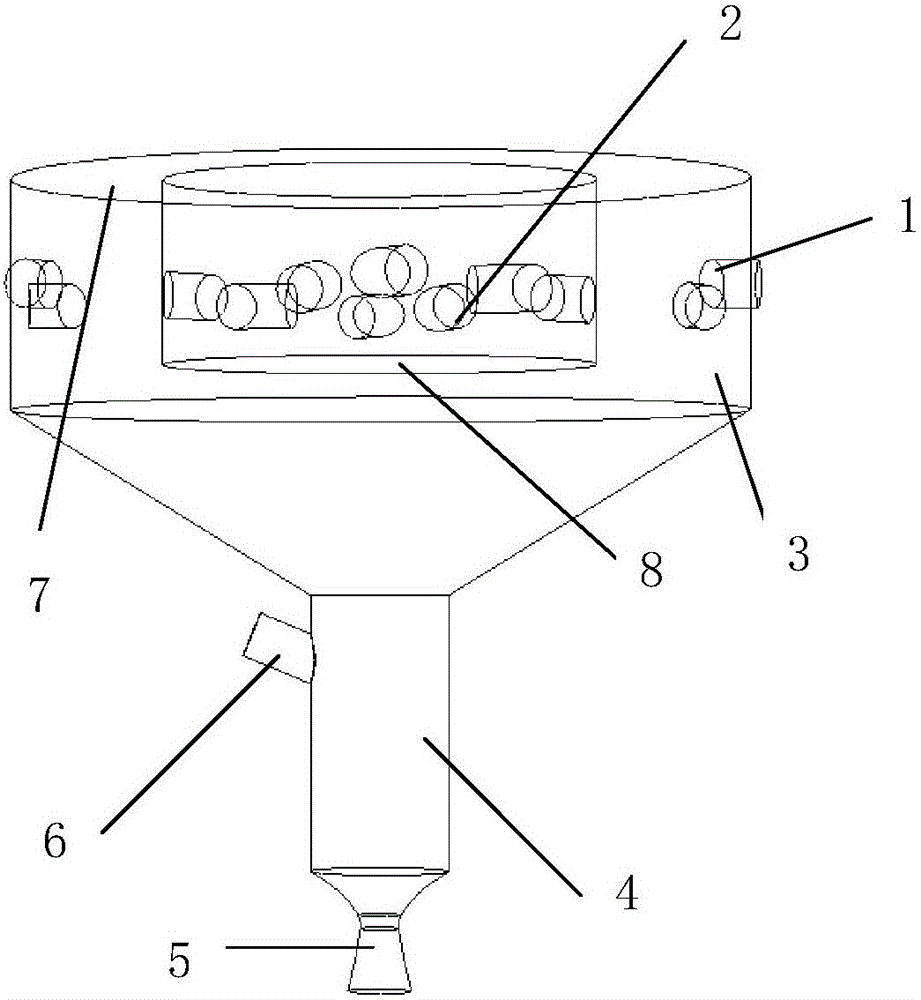

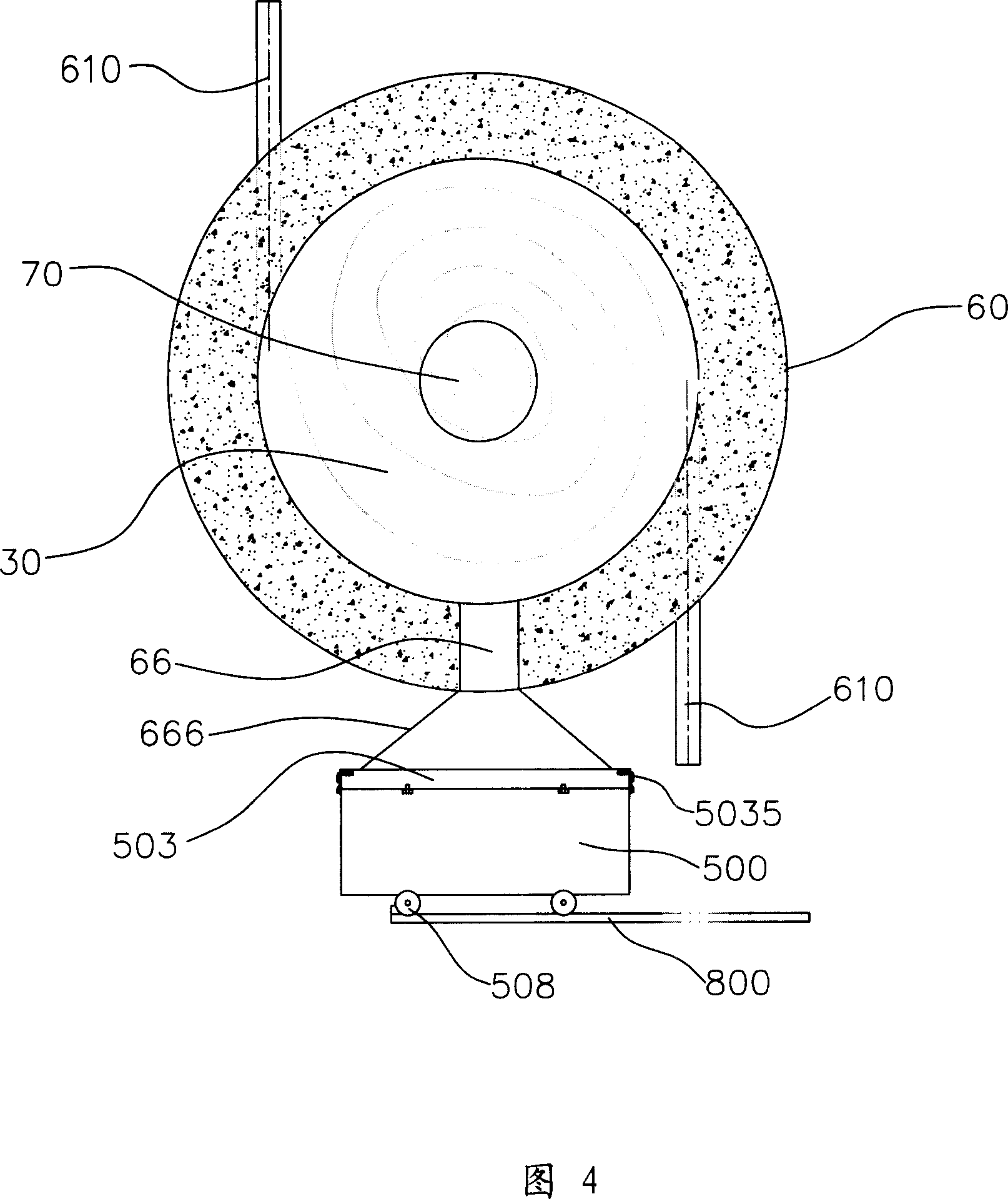

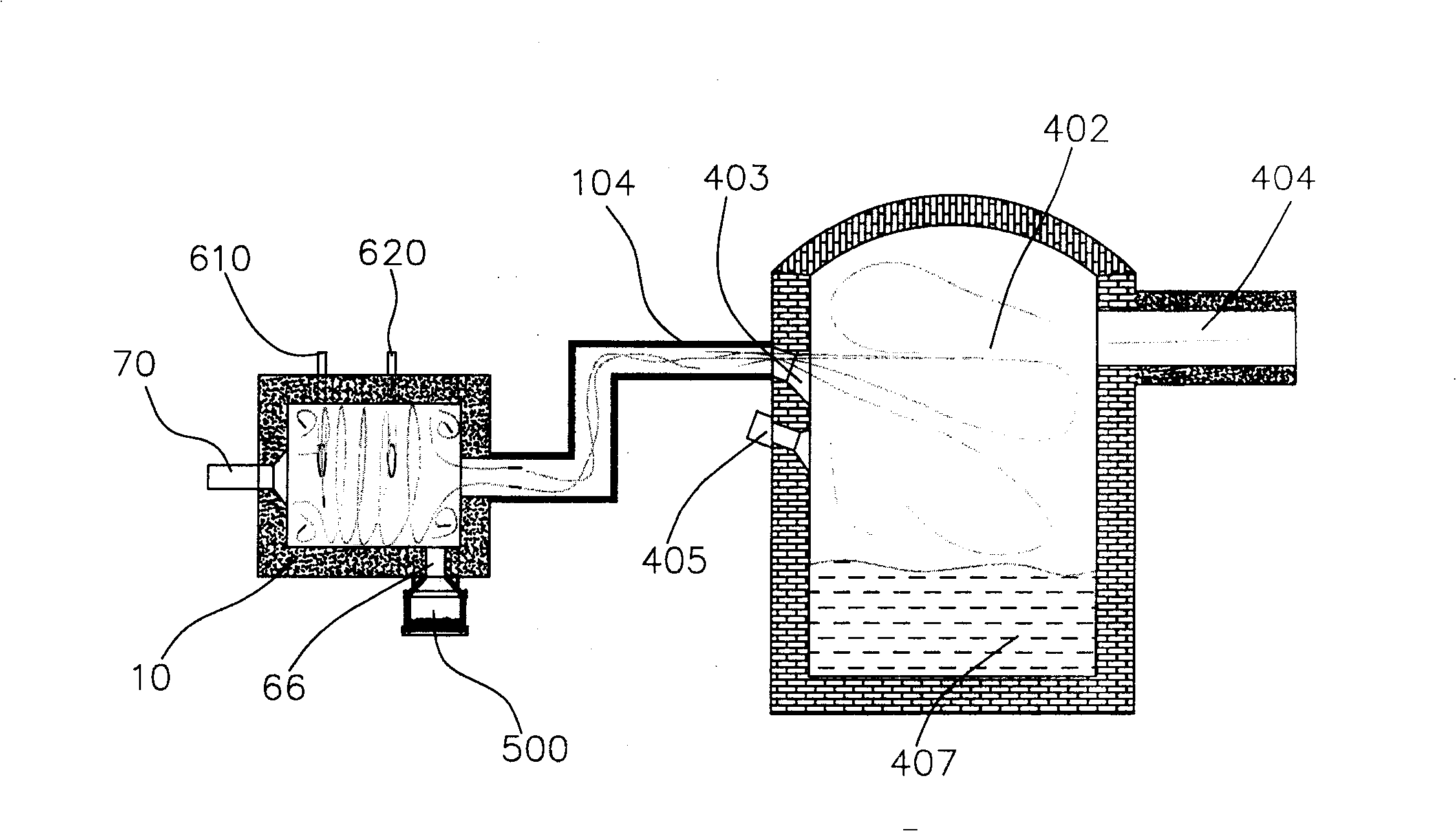

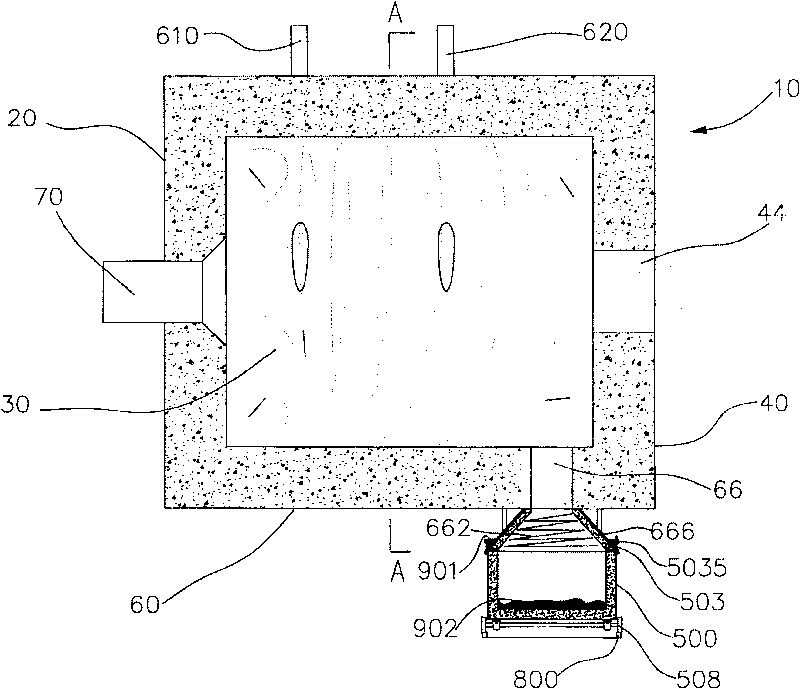

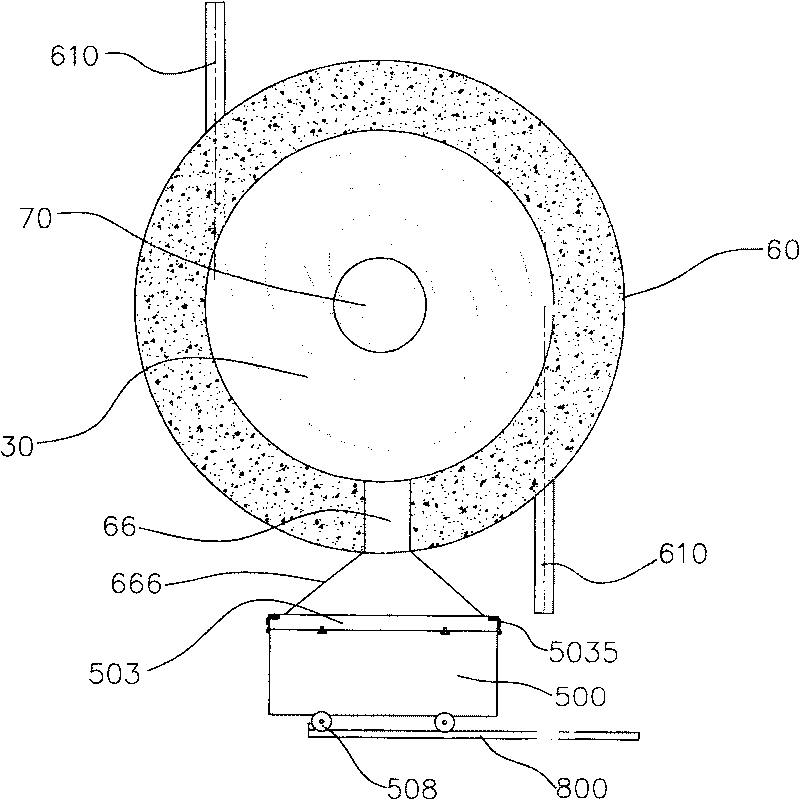

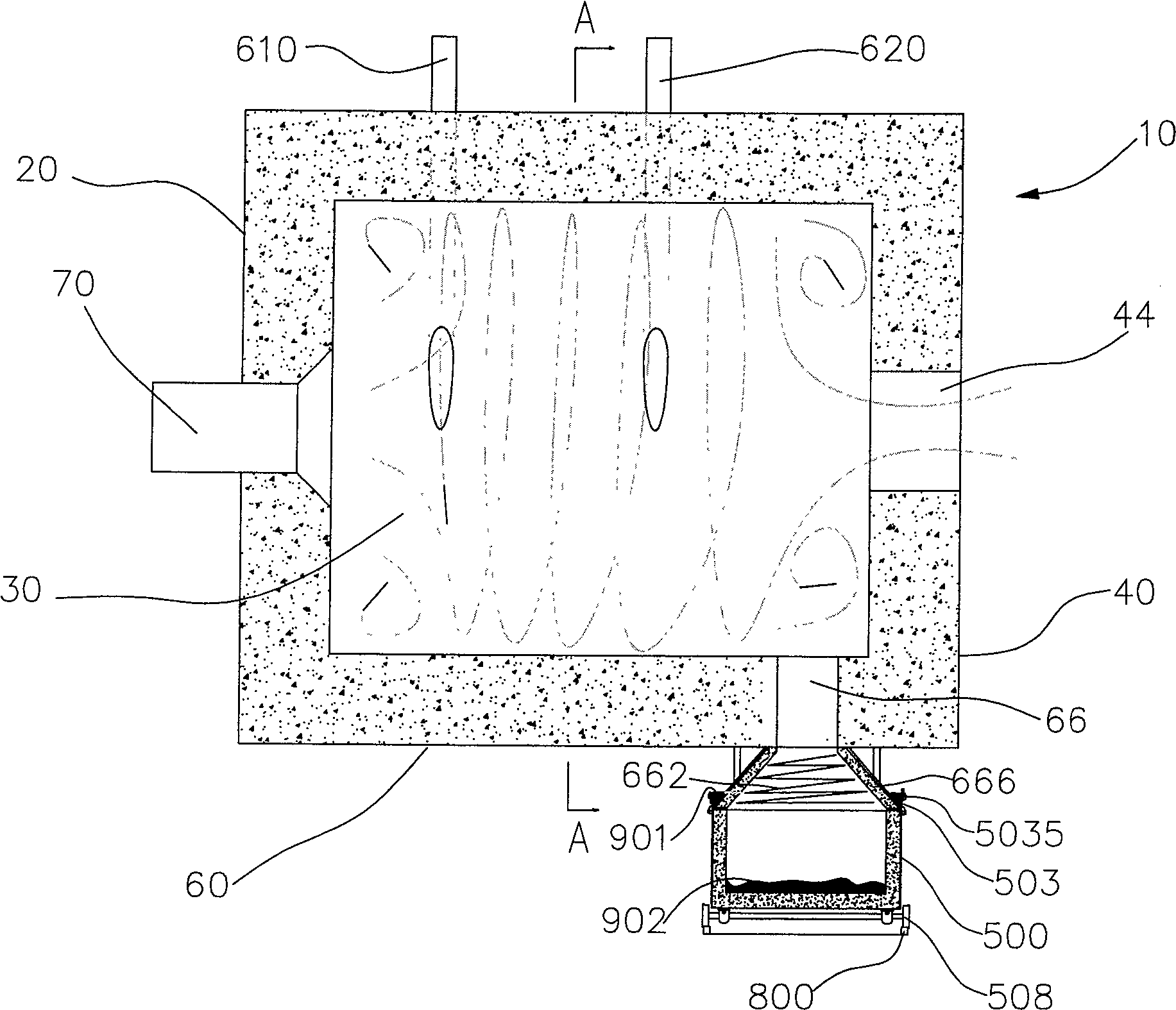

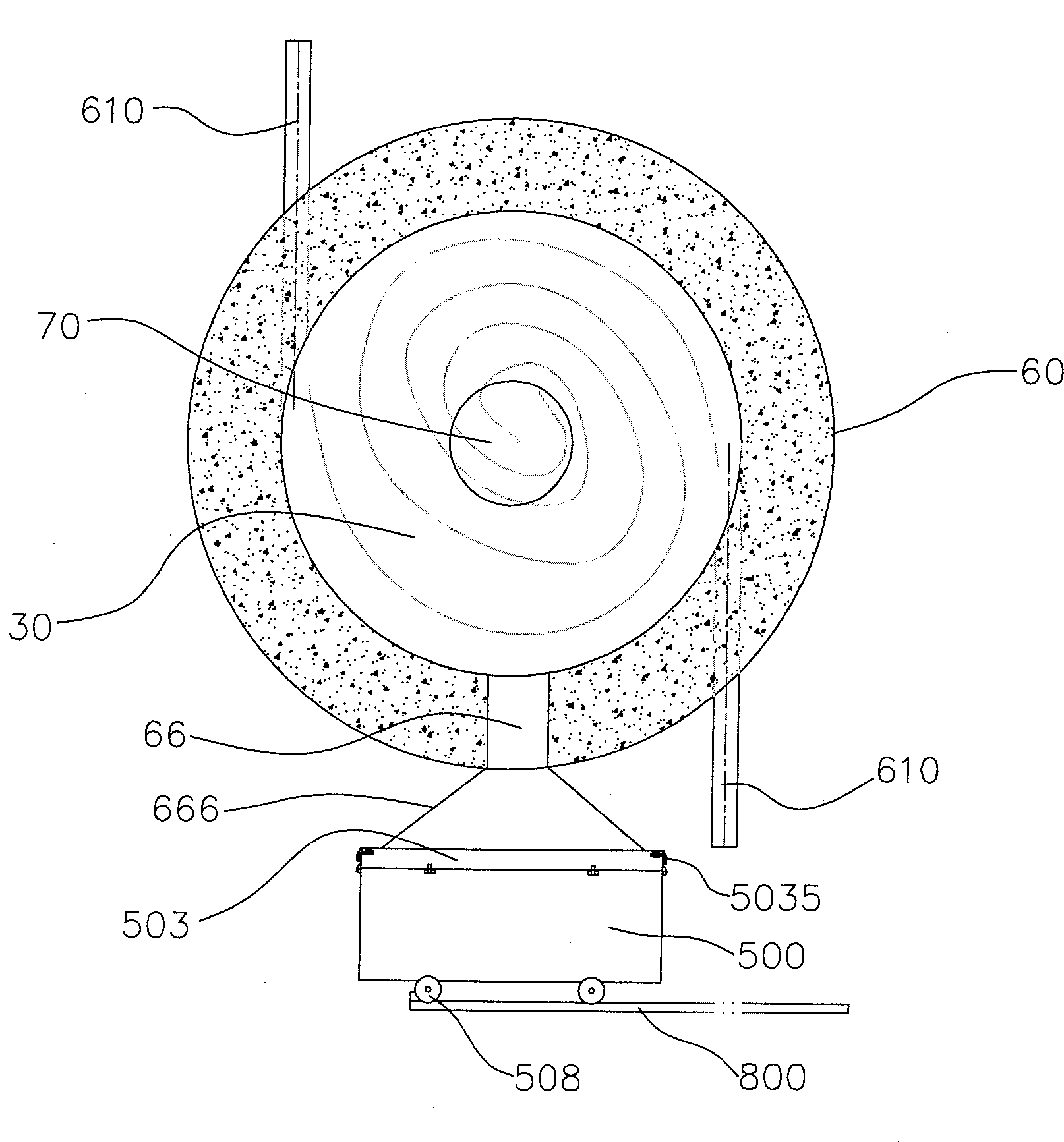

Oscillating type fodder mixing device with up-down stirring function

InactiveCN108097136AMix vigorouslyWell mixedShaking/oscillating/vibrating mixersFeeding-stuffFixed framePush pull

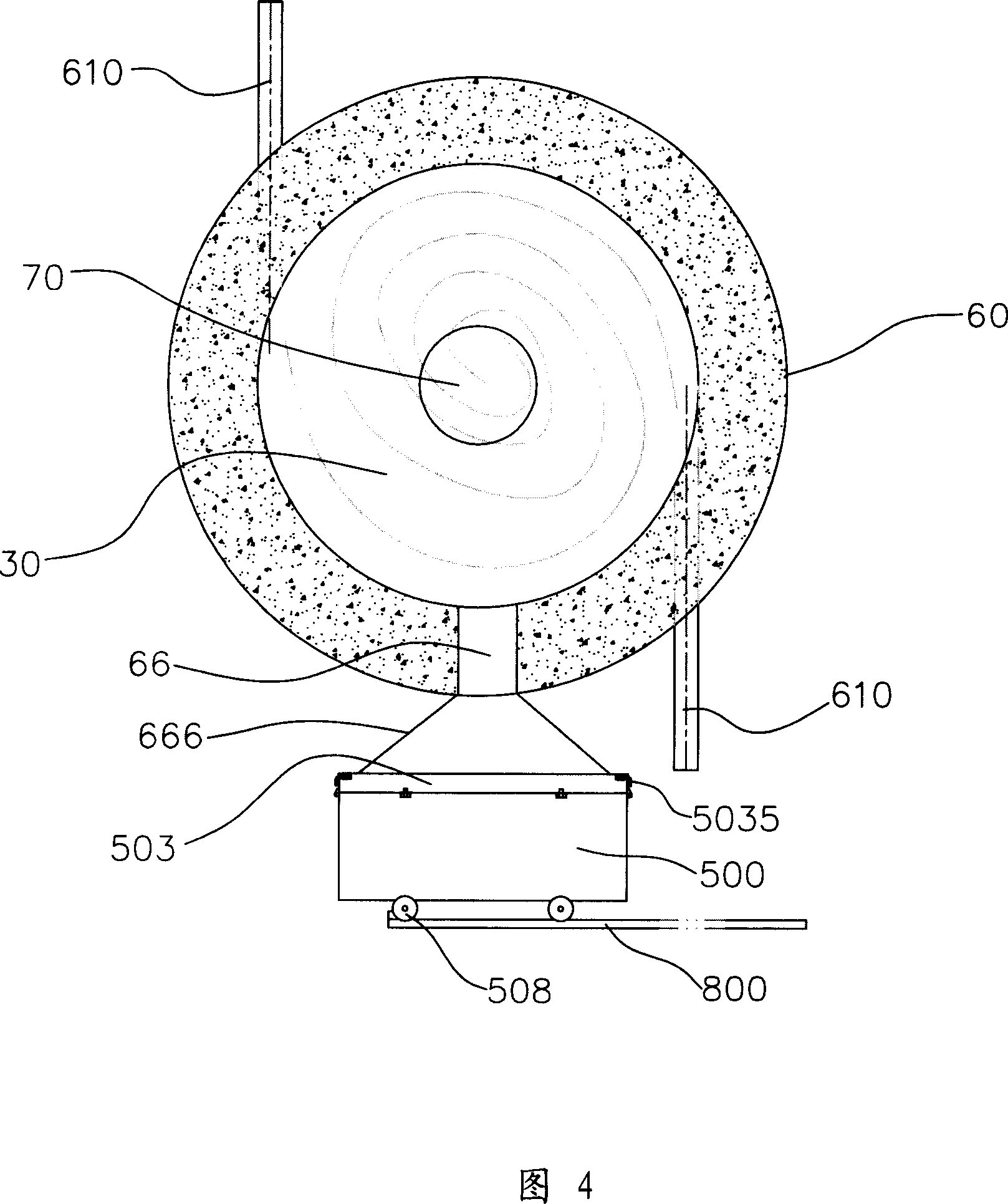

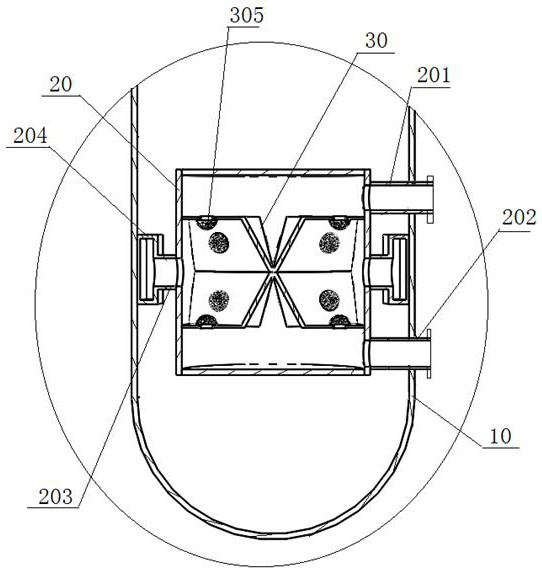

The invention discloses an oscillating type fodder mixing device with an up-down stirring function. The oscillating type fodder mixing device comprises a base plate and a mixing box. A supporting vertical plate is arranged on the base plate, the mixing box is fixed to the supporting vertical plate through a supporting rotary shaft, the supporting rotary shaft is rotatably connected with the supporting vertical plate, a lifting conveying cylinder is arranged at the center of the interior of the mixing box, a screw conveyor is arranged in the lifting conveying cylinder, an oscillating motor is arranged on one side of the supporting vertical plate, the oscillating motor is fixed to the supporting vertical plate through a fixing frame, a driving round disc is arranged on a main shaft of the oscillating motor, and an eccentric concave boss is arranged on the end face of the driving round disc. One end of a push-pull cross rod is connected with the side face of the supporting vertical platethrough a limiting mechanism, a vertically upward driving rack is arranged in the middle of the push-pull cross rod, and the driving rack is engaged with a driving gear arranged on a supporting crossshaft. The oscillating type fodder mixing device is simple in structure, good in mixing effect, convenient to operate and high in practicality.

Owner:COMMON TECH DEV CO LTD

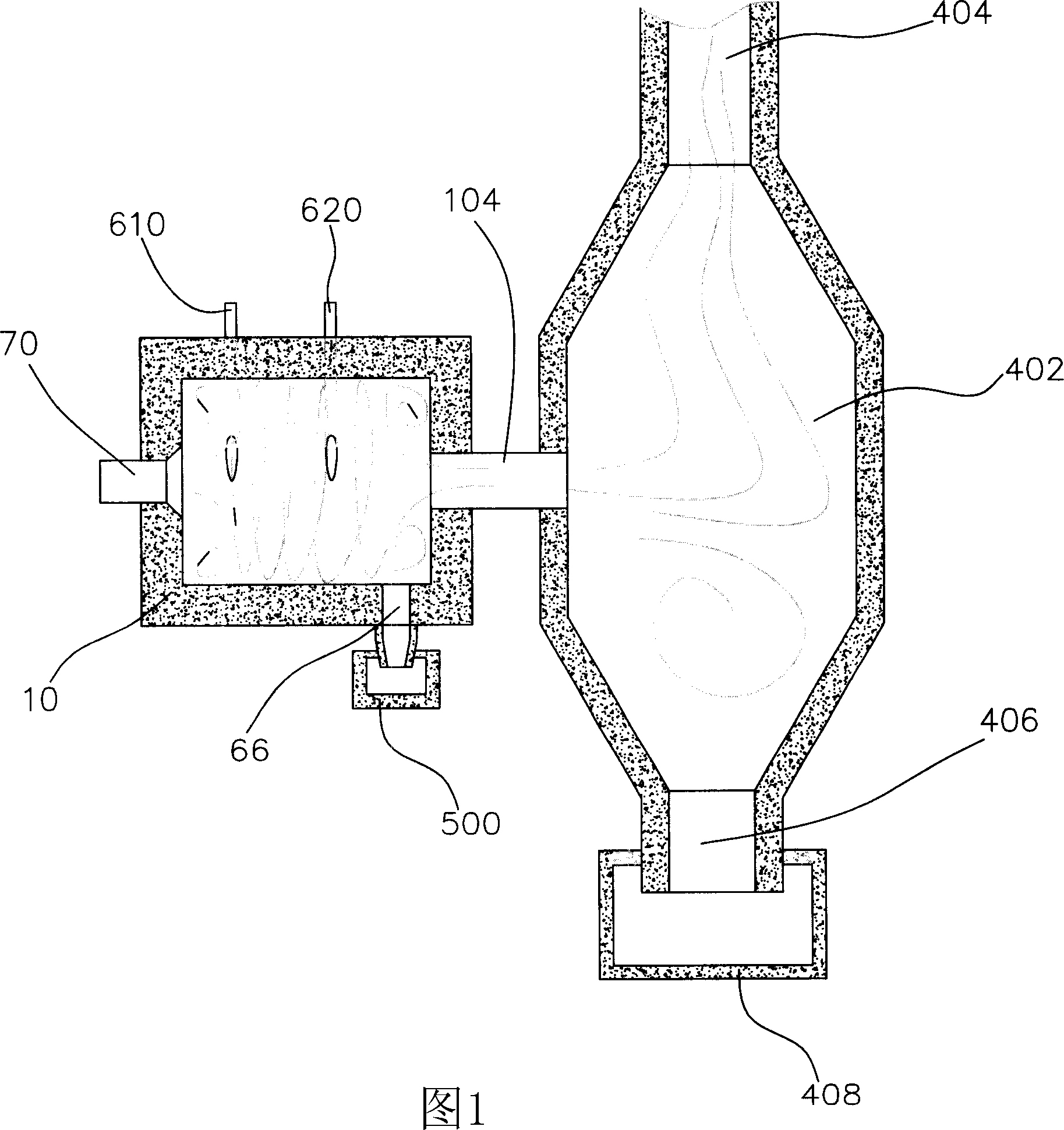

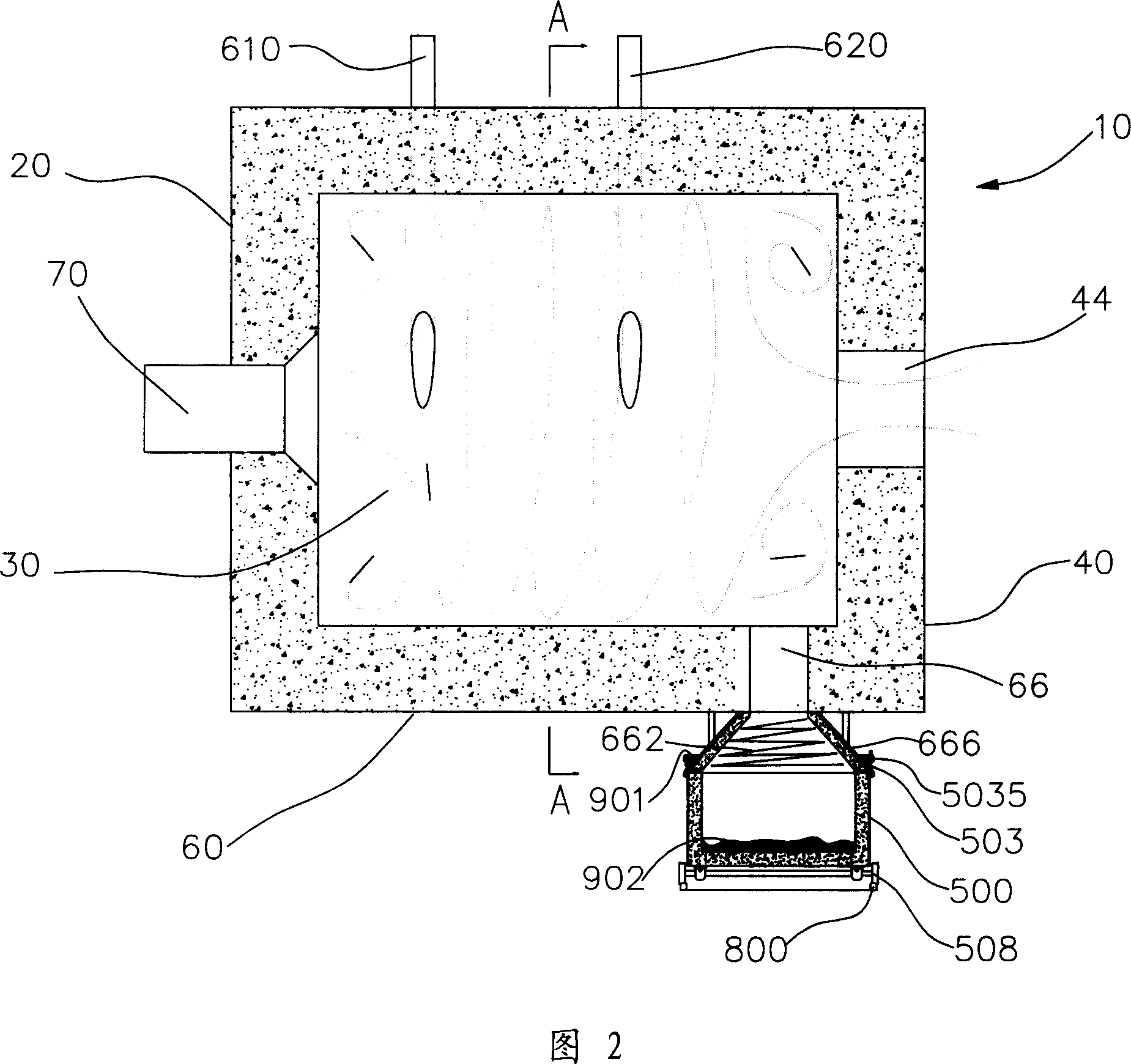

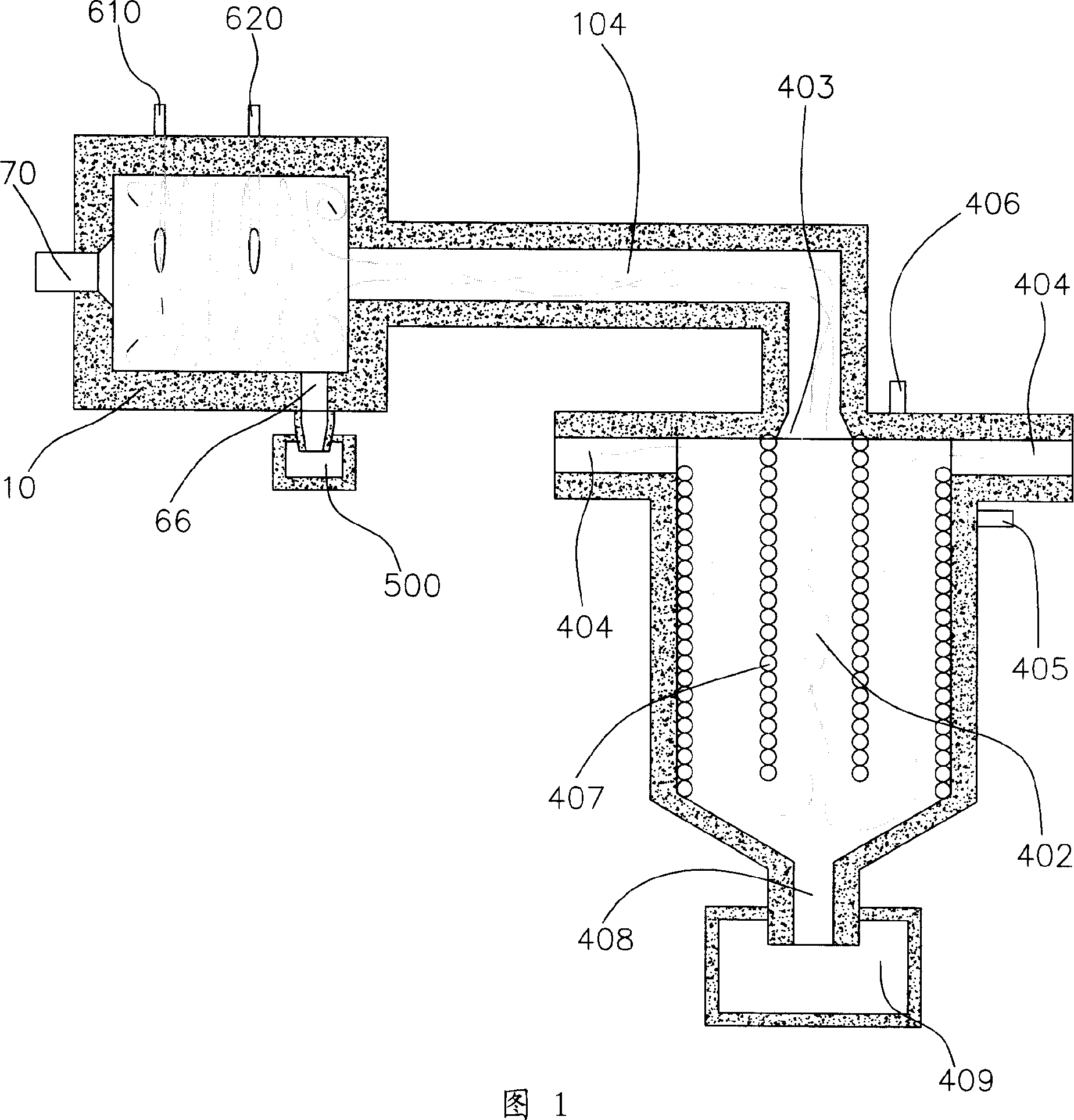

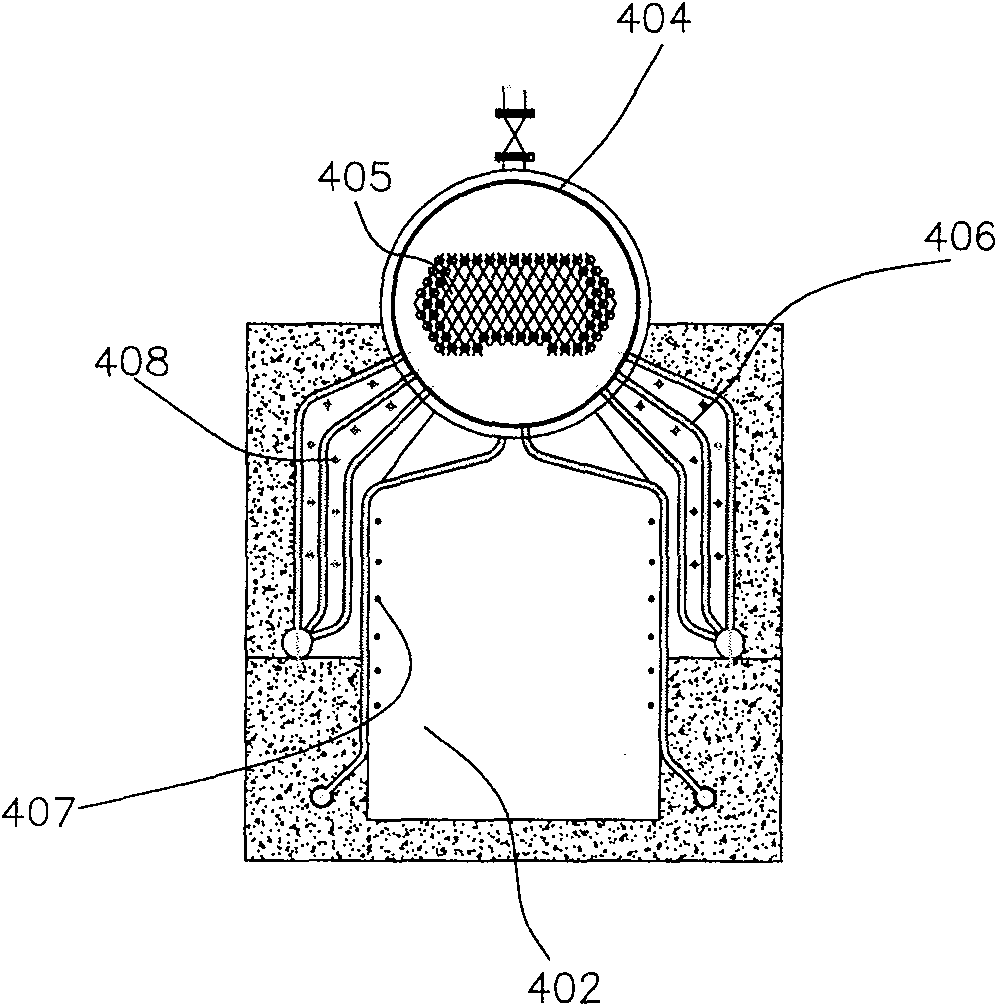

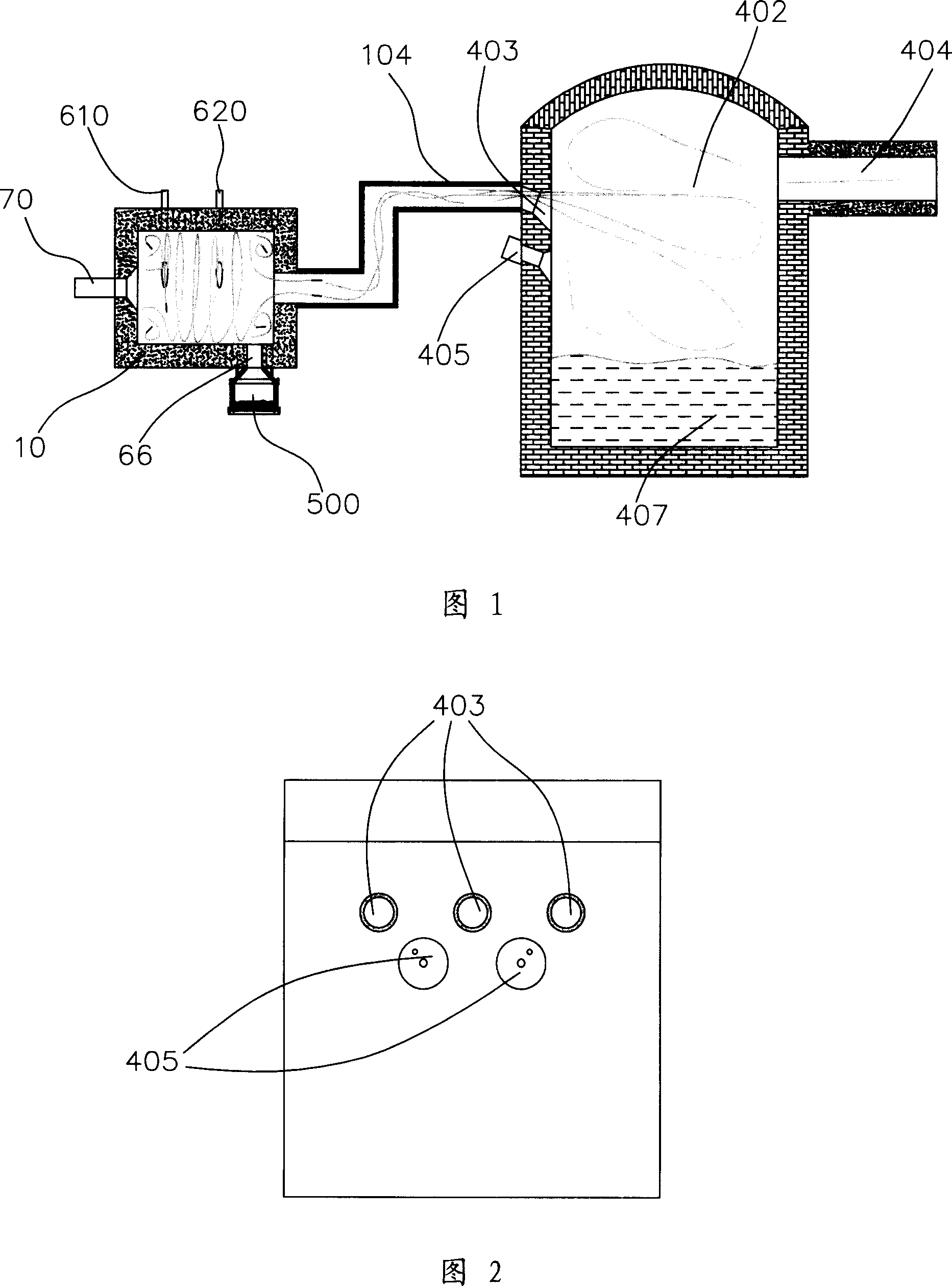

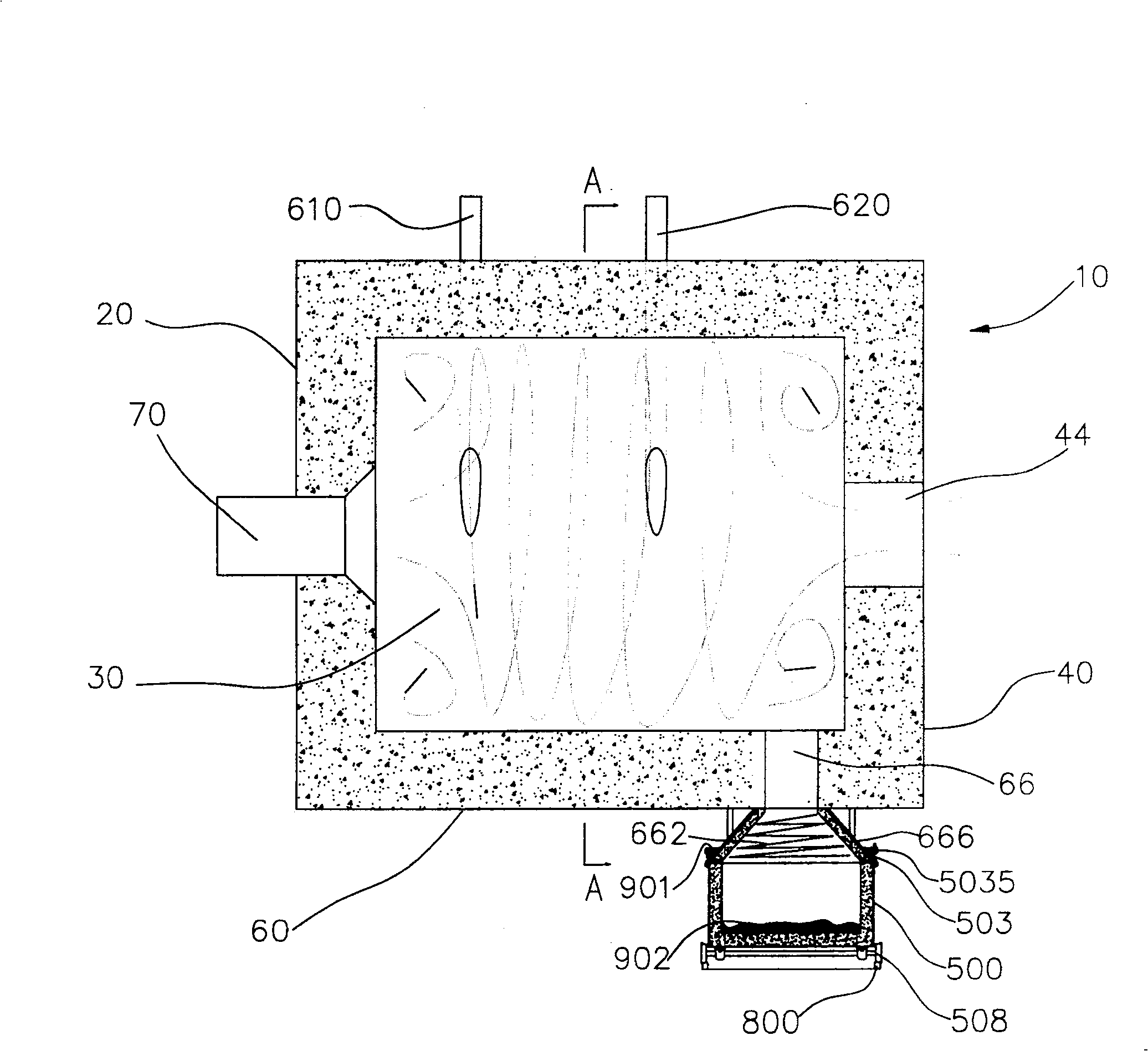

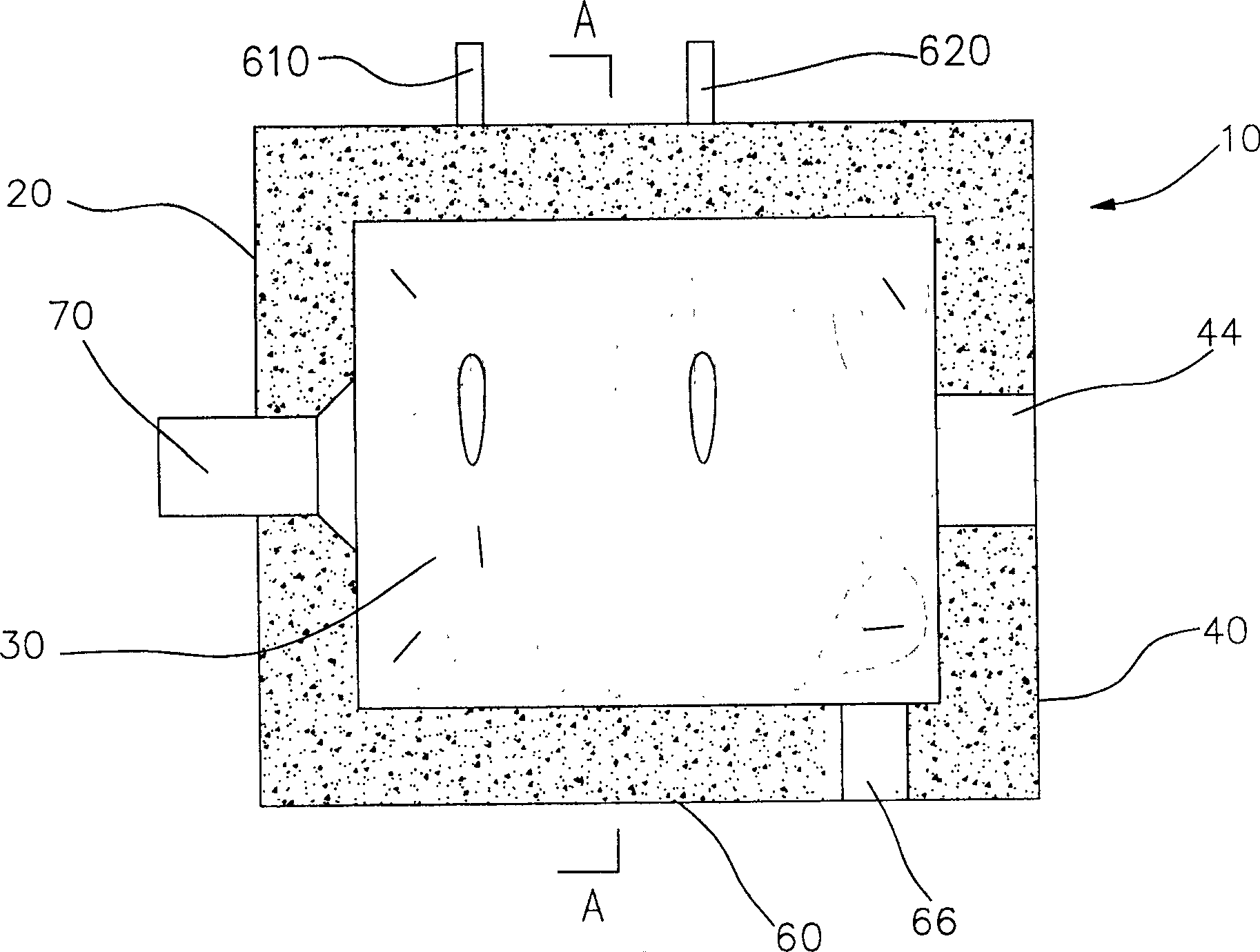

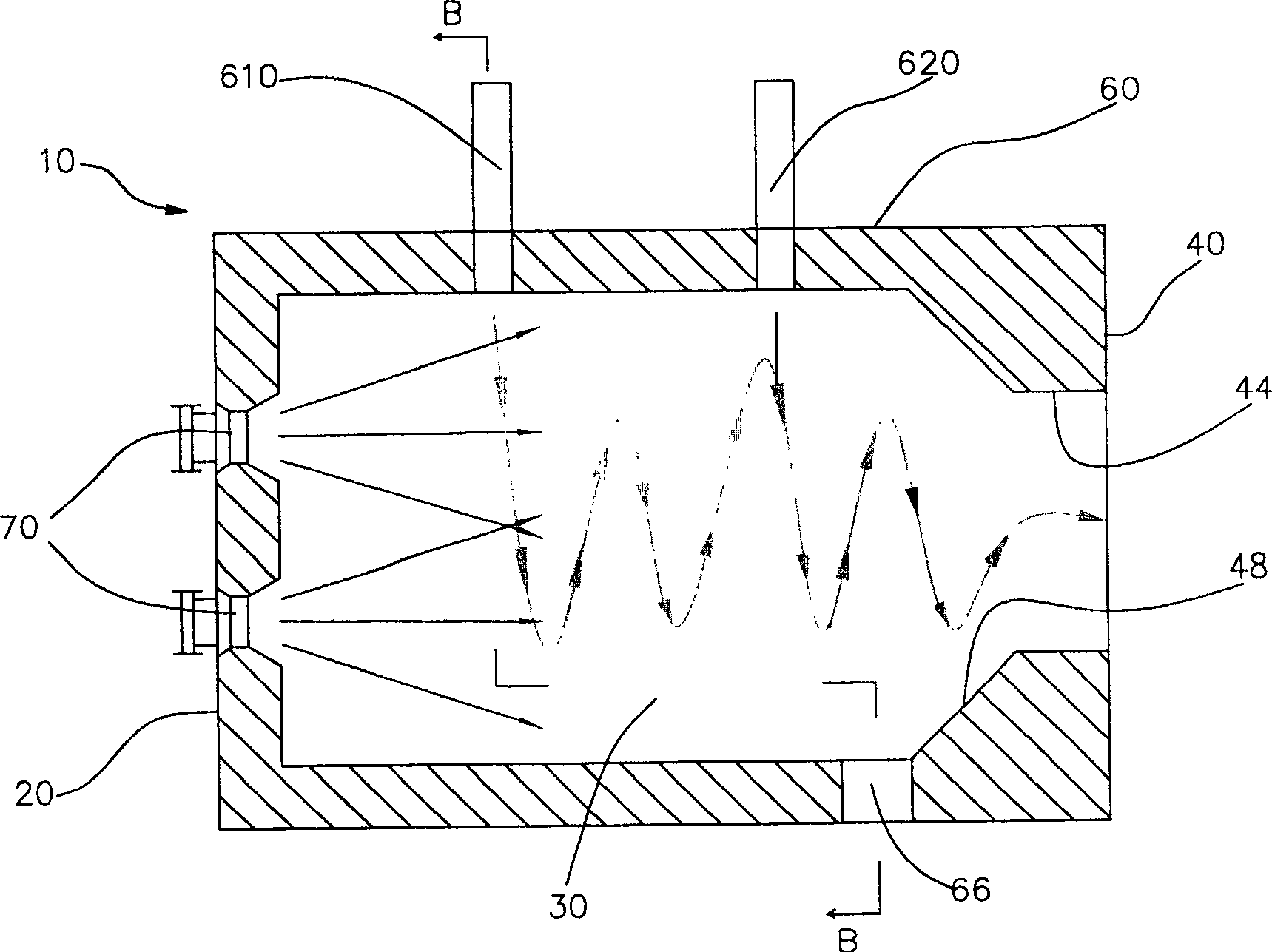

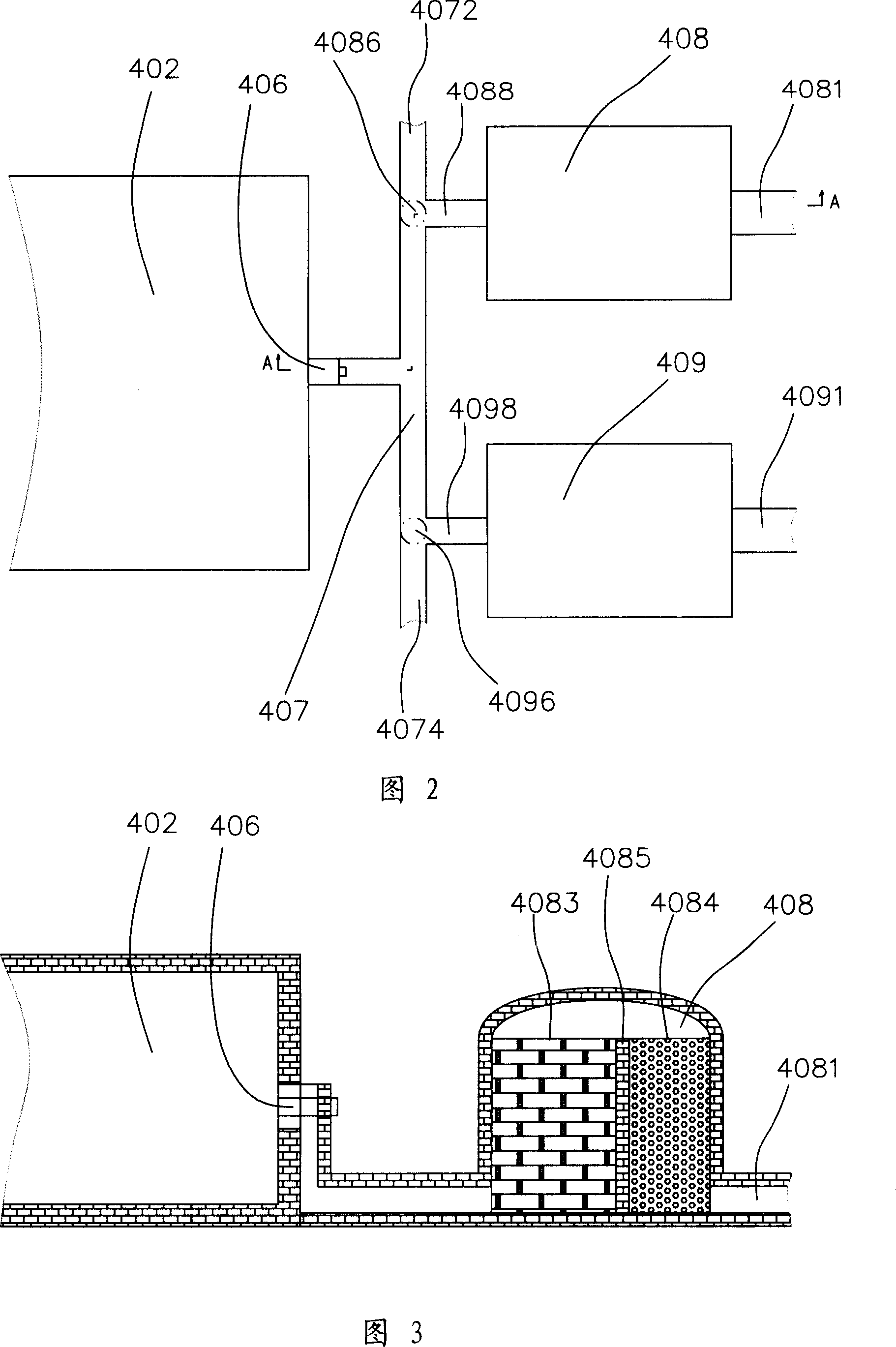

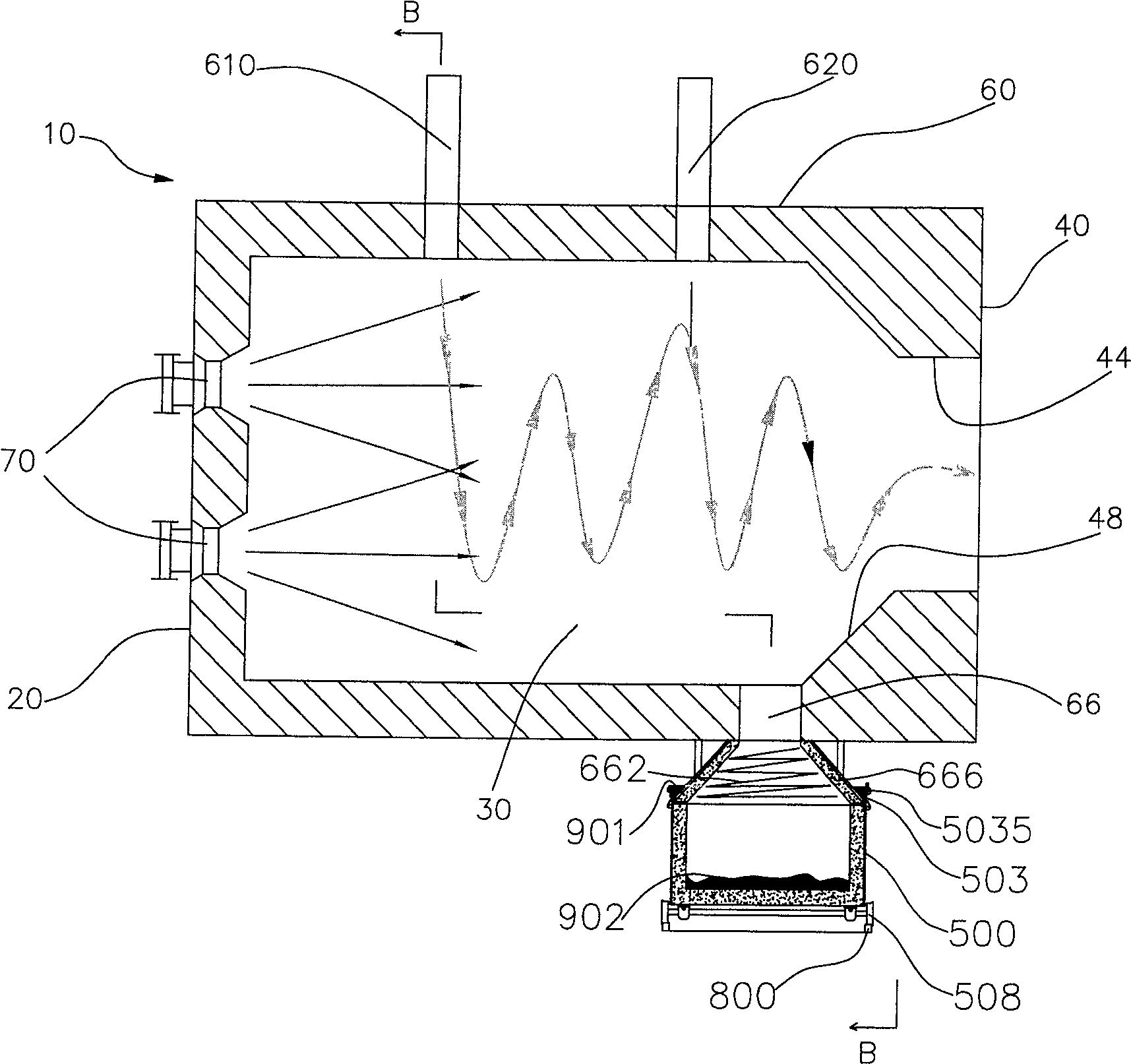

Ceramic hot-blast furnace by emusified coking slurry cyclone burner

InactiveCN101029728AQuality assuranceImprove cleanlinessCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneSlurry

This invention discloses a ceramic air heating furnace with the emulsification slurry wind burning device including vertical air heating furnace and the emulsification slurry wind burning device. The air heating furnace includes an egg-shape furnace chamber and the heat air opening. The emulsification burning device consists of a front end wall, back end wall and the side crust inside which forms a cylindraceous burning space. There are at least one emulsification burning device and at least a fuel burning device or at least air burning device. The back end wall has an outlet opening which connects to the egg-shape furnace chamber by the pipe. The side of the crust sets two or more tangential wind inlet openings and there are at least one dreg outlet opening near the back end wall at the side of the bottom of the burning space. The ceramic air heating furnace of this invention utilizes the emulsification burning device and the emulsification slurry as fuel so as to save the cost and maximize the utilization of the resource.

Owner:GUANGZHOU DEVOTION THERMAL TECH

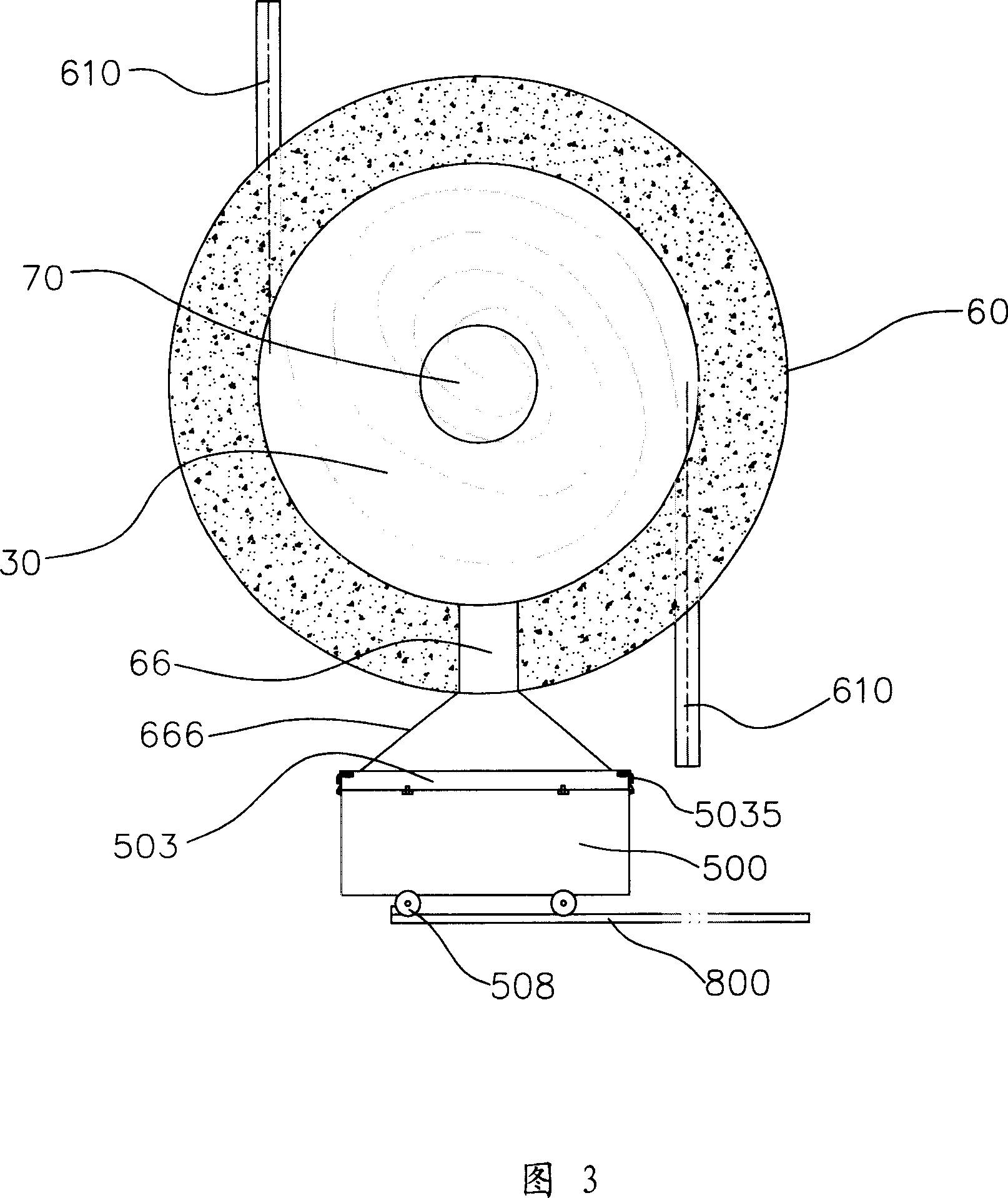

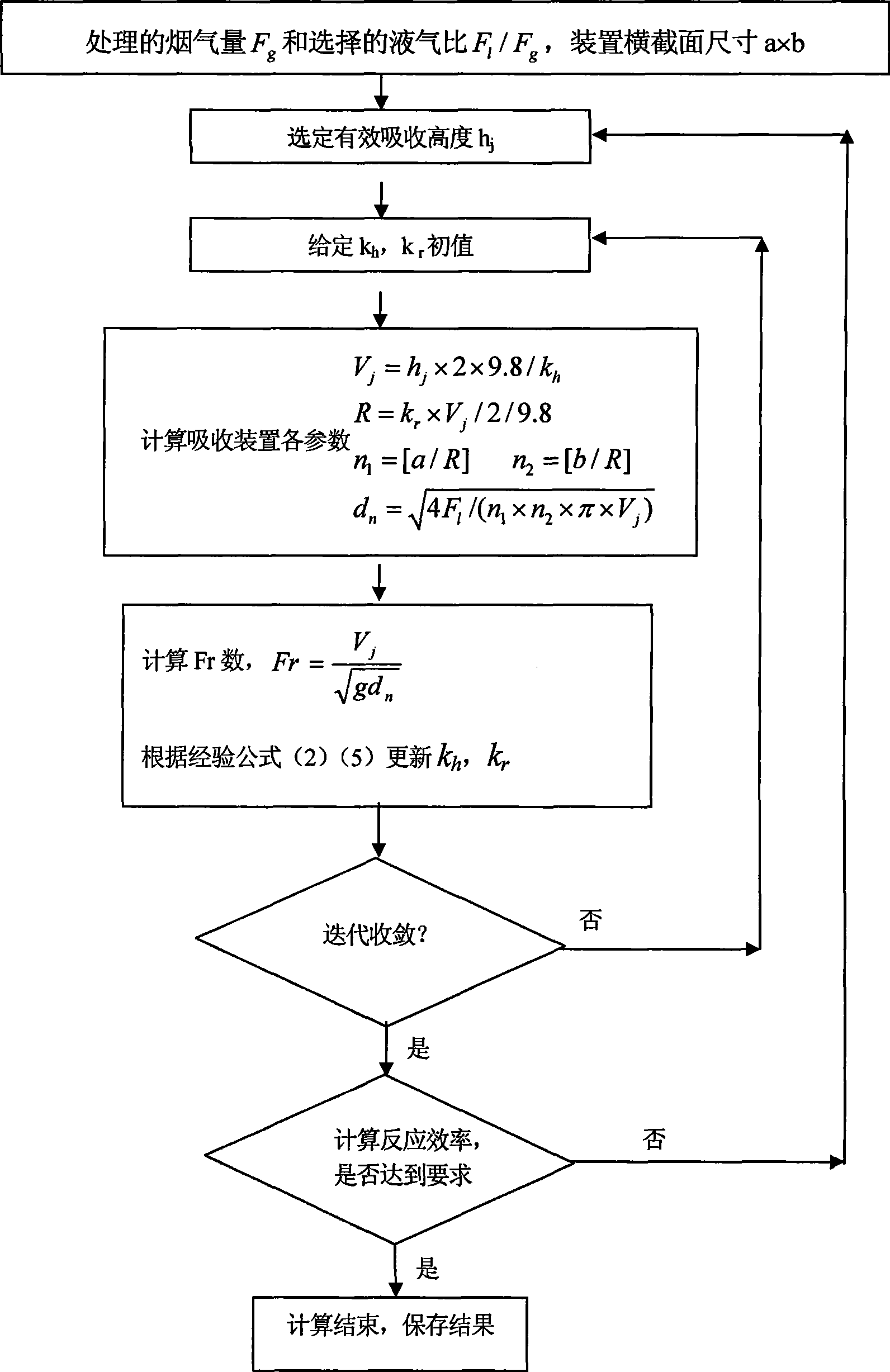

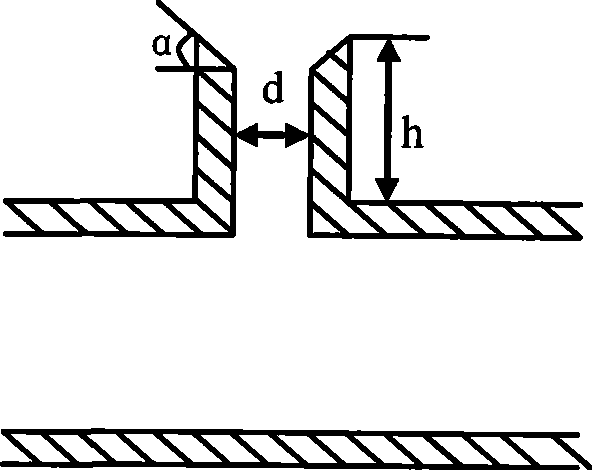

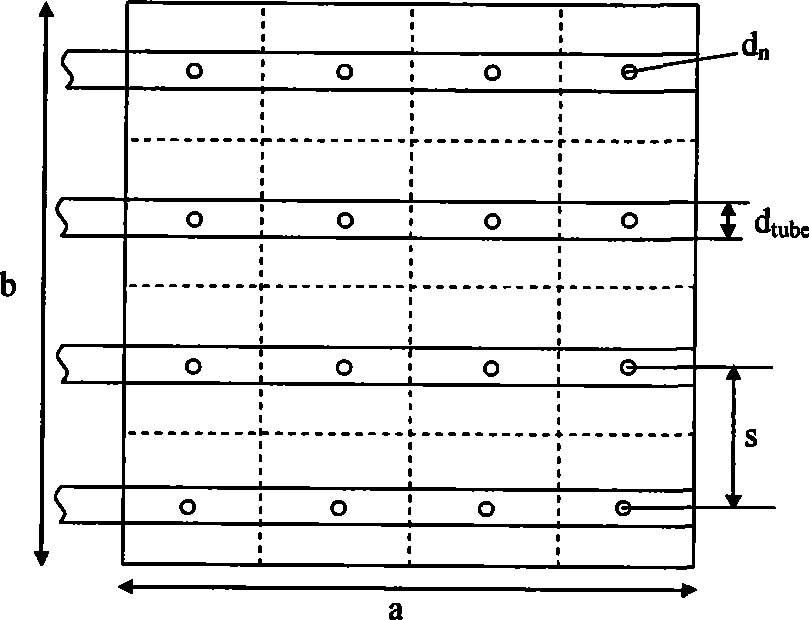

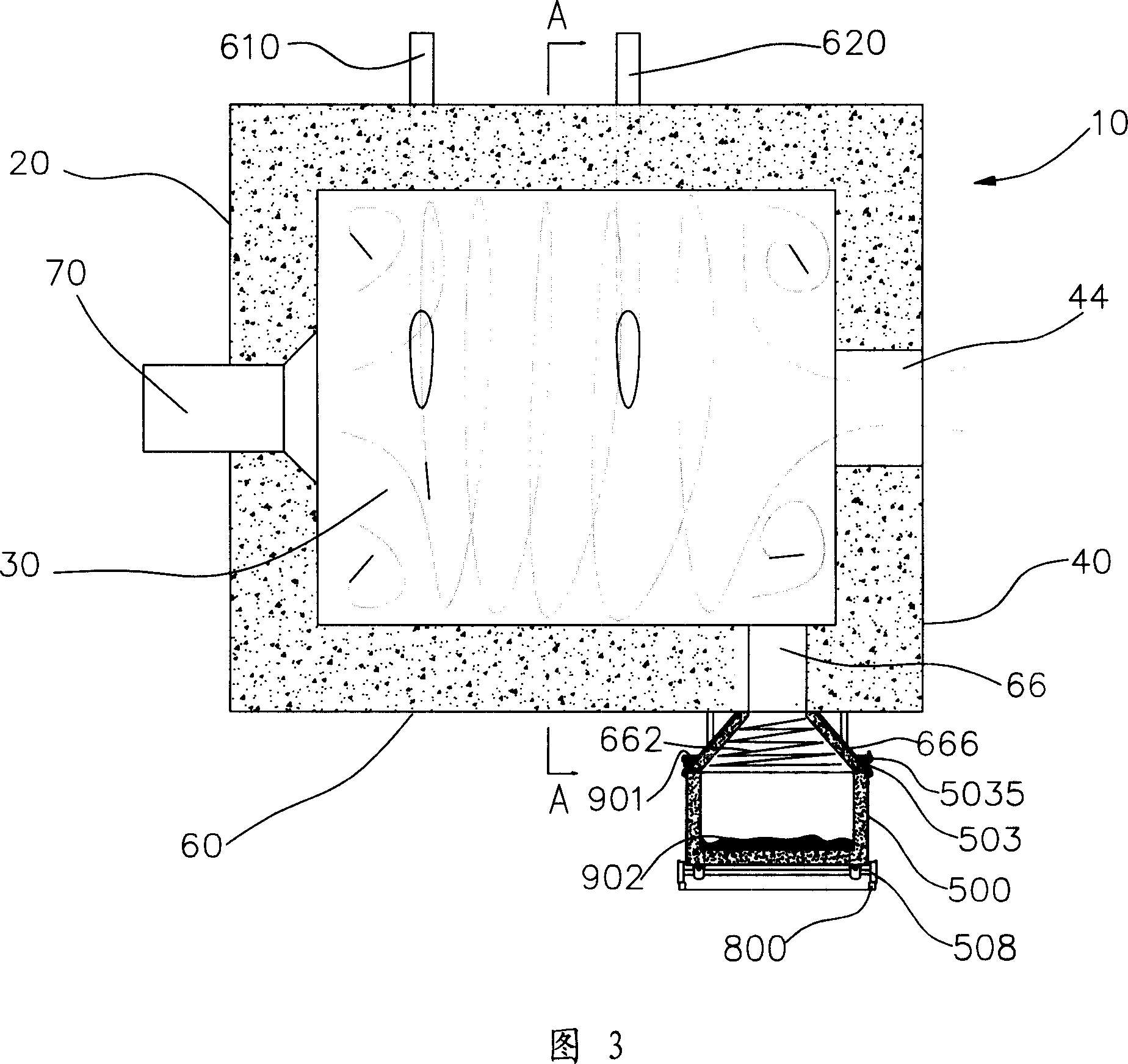

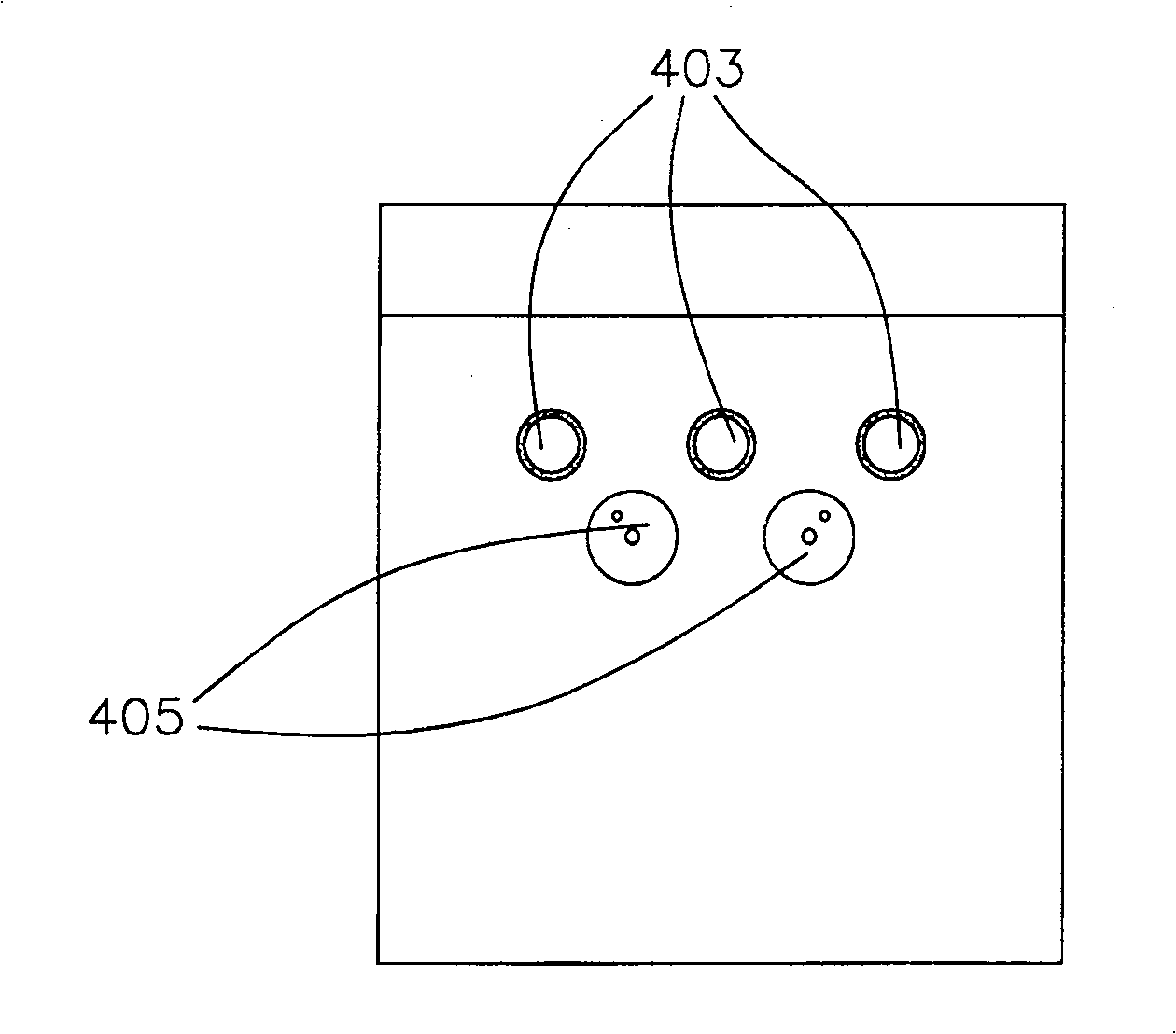

Design method of fluid curtain bed gas-liquid contact reaction device

InactiveCN101391176AEasy to implementImprove accuracyDispersed particle separationChemical/physical/physico-chemical nozzle-type rreactorsGas liquid reactionAlgebraic solution

The invention discloses a design method of a fluid curtain bed gas-liquid contact reaction device, when designing the gas-liquid reaction device, the known quantities are: the liquid / gas ratio of the device (F1 / Fg), the amount of flue gas to be treated (Fg), the scale of the reaction device (cross-sectional dimension axb), parameters needing to be solved are all the parameters of an arrangement method and an apparatus of uniform fluid curtain of a liquid phase jet apparatus, which include the number of nozzles (n1xn2), the nozzle diameter dn, the space s between nozzles, the diameter of a jet main pipe d(tube), and the effective absorption height hj of the reaction device when meeting the requirement of reaction efficiency. A solving method bases on the experimental results of the unit, three empirical formulas are introduced, then the algebraic solution is adopted, and the device has advantages of easy implementation and high accuracy.

Owner:XI AN JIAOTONG UNIV

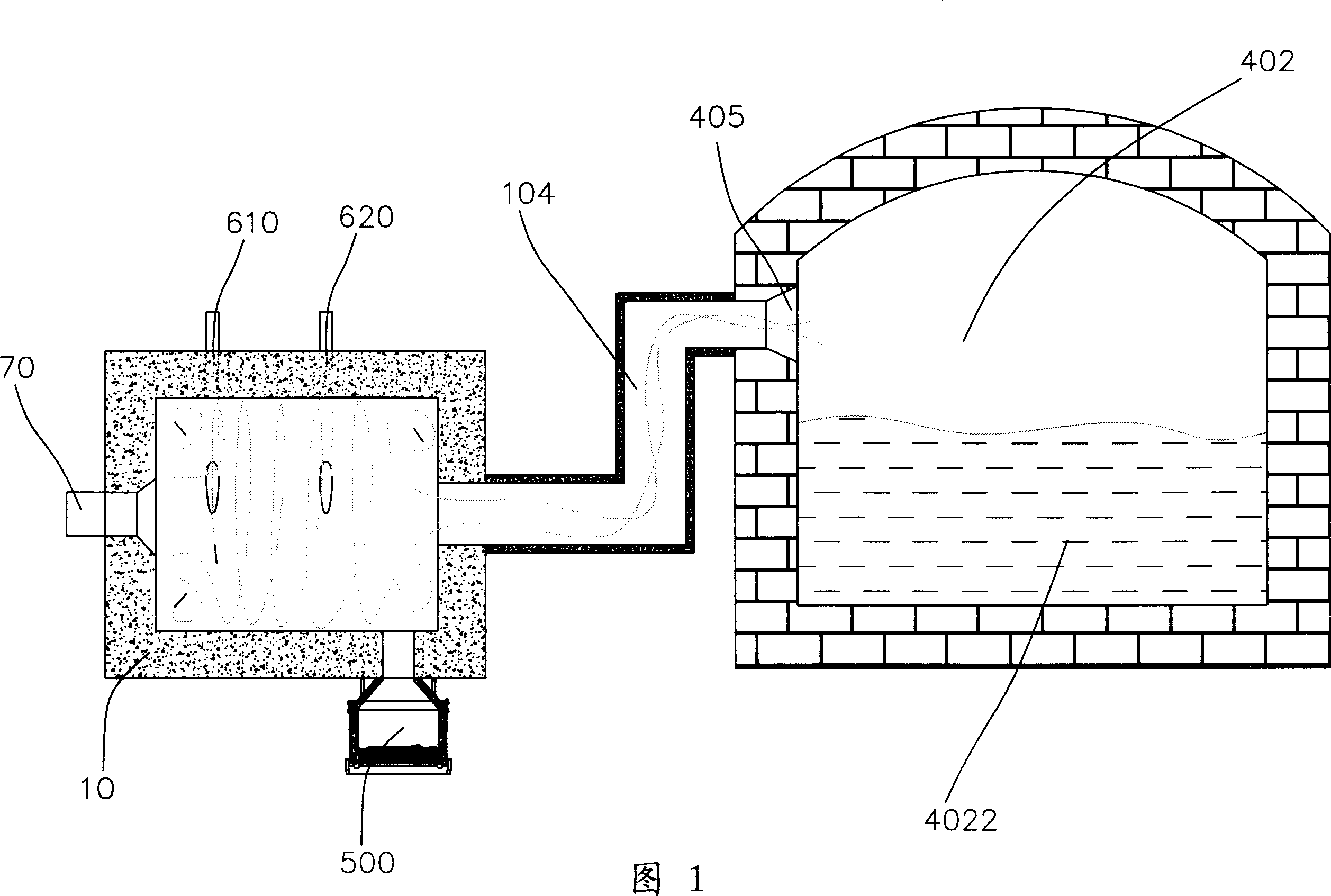

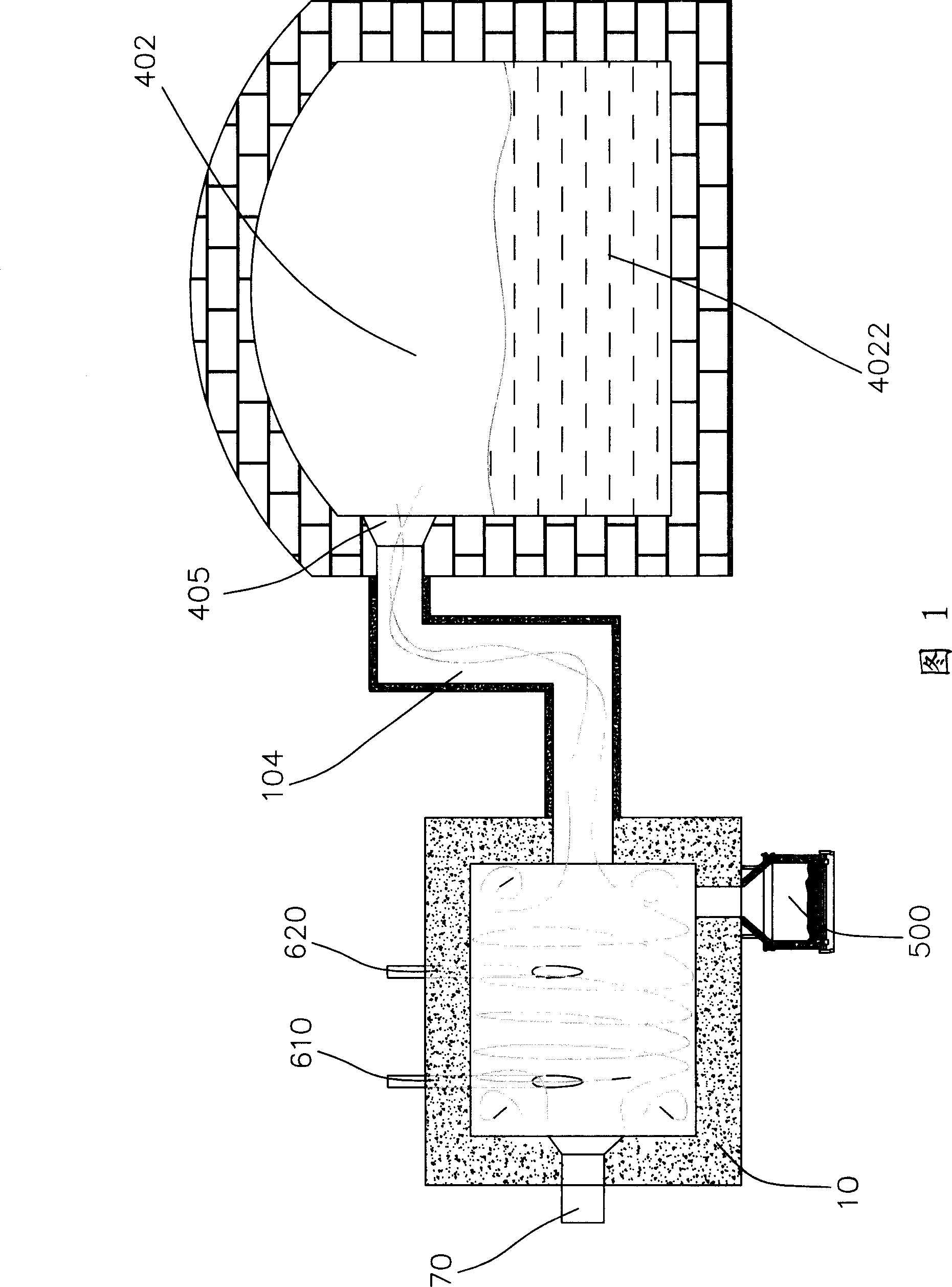

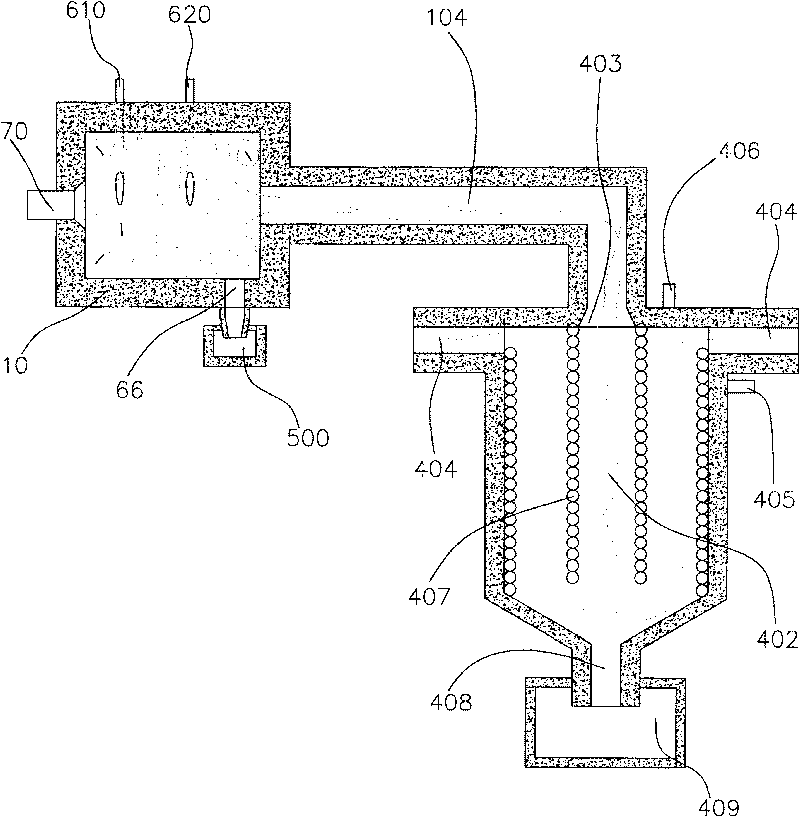

Glass kiln with emulsified coke slurry burner

InactiveCN101020596AEfficient and stable combustionMake up for the shortcomings of low calorific valueGlass furnace apparatusGlass productionBurn unitsBrick

The glass kiln with emulsified coke slurry burner includes one kiln body and one emulsified coke slurry burner. The kiln body includes one hearth, one flame inlet and one fume outlet. The emulsified coke slurry burner includes one casing forming one inside cylindrical burning space, at least one emulsified coke slurry burning unit, at least one oil / gas burner, one outlet communicated via hot blast pipe to the flame inlet of the hearth. The glass kiln includes also two or more switchable heat accumulating chambers connected via pipeline with the fume outlet of the kiln body. The present invention has double heat accumulation with lattice brick and ceramic ball reaching a heat accumulating temperature as high as 1200 deg.c to make up the low heat value emulsified coke slurry.

Owner:GUANGZHOU DEVOTION THERMAL TECH

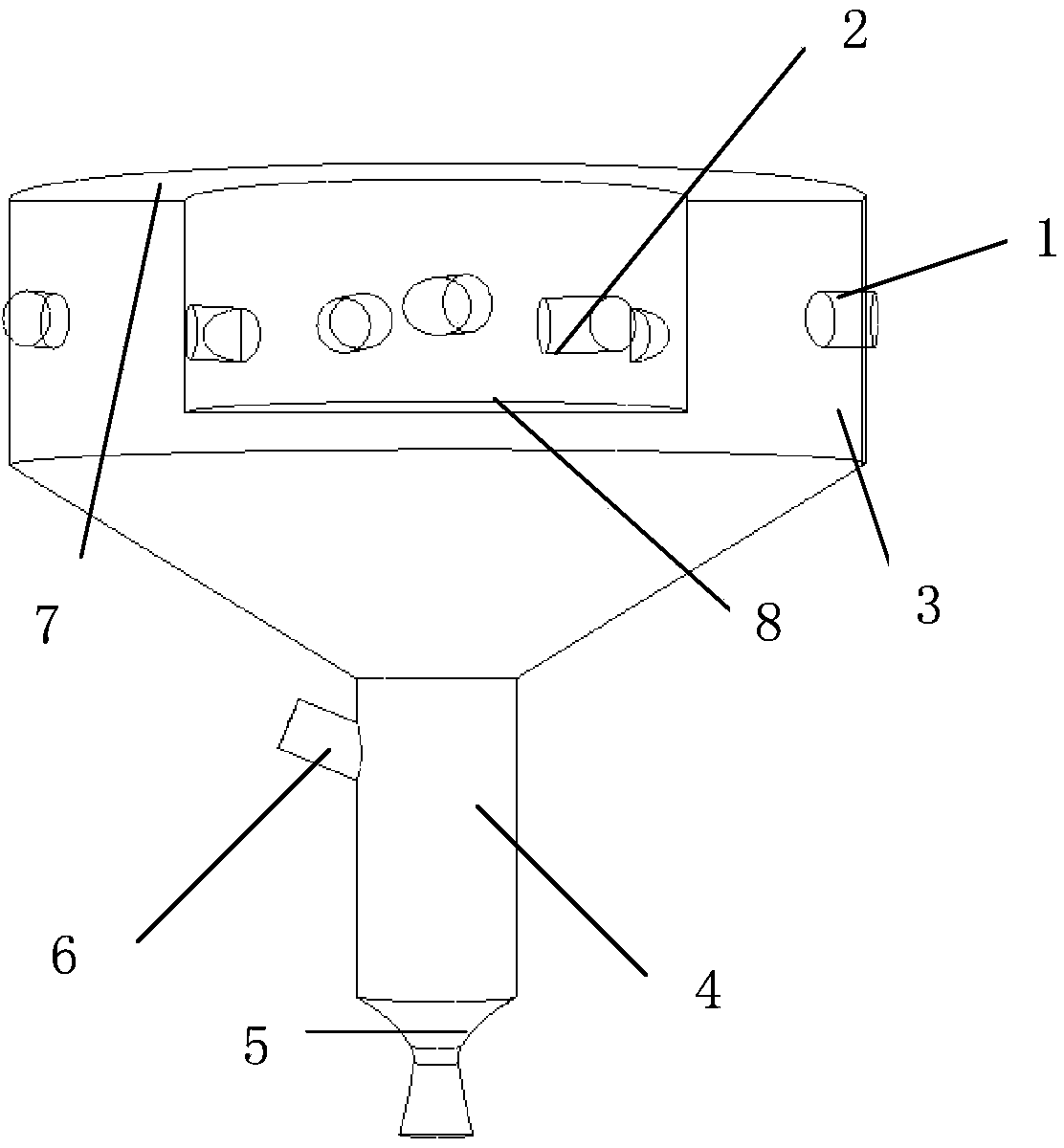

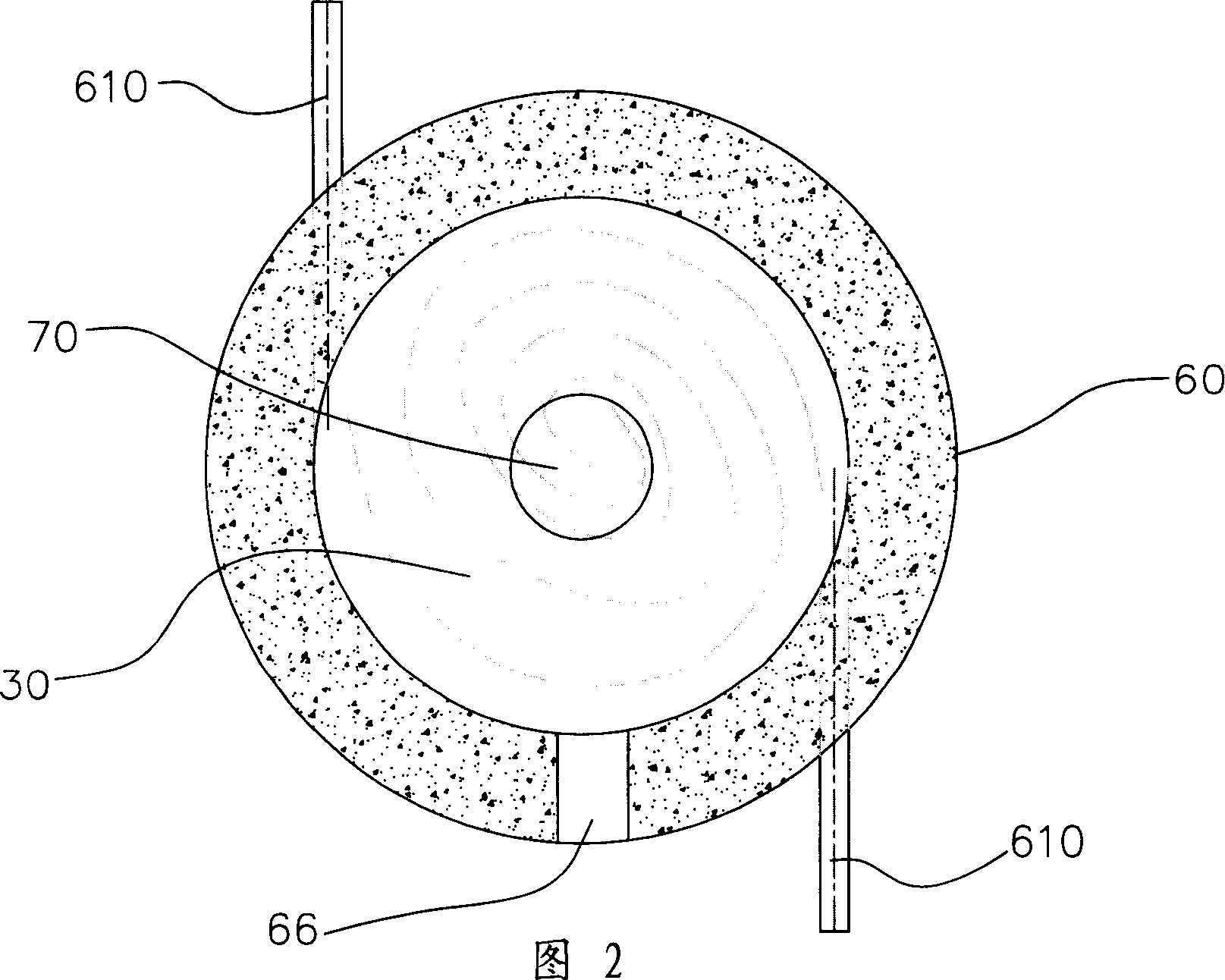

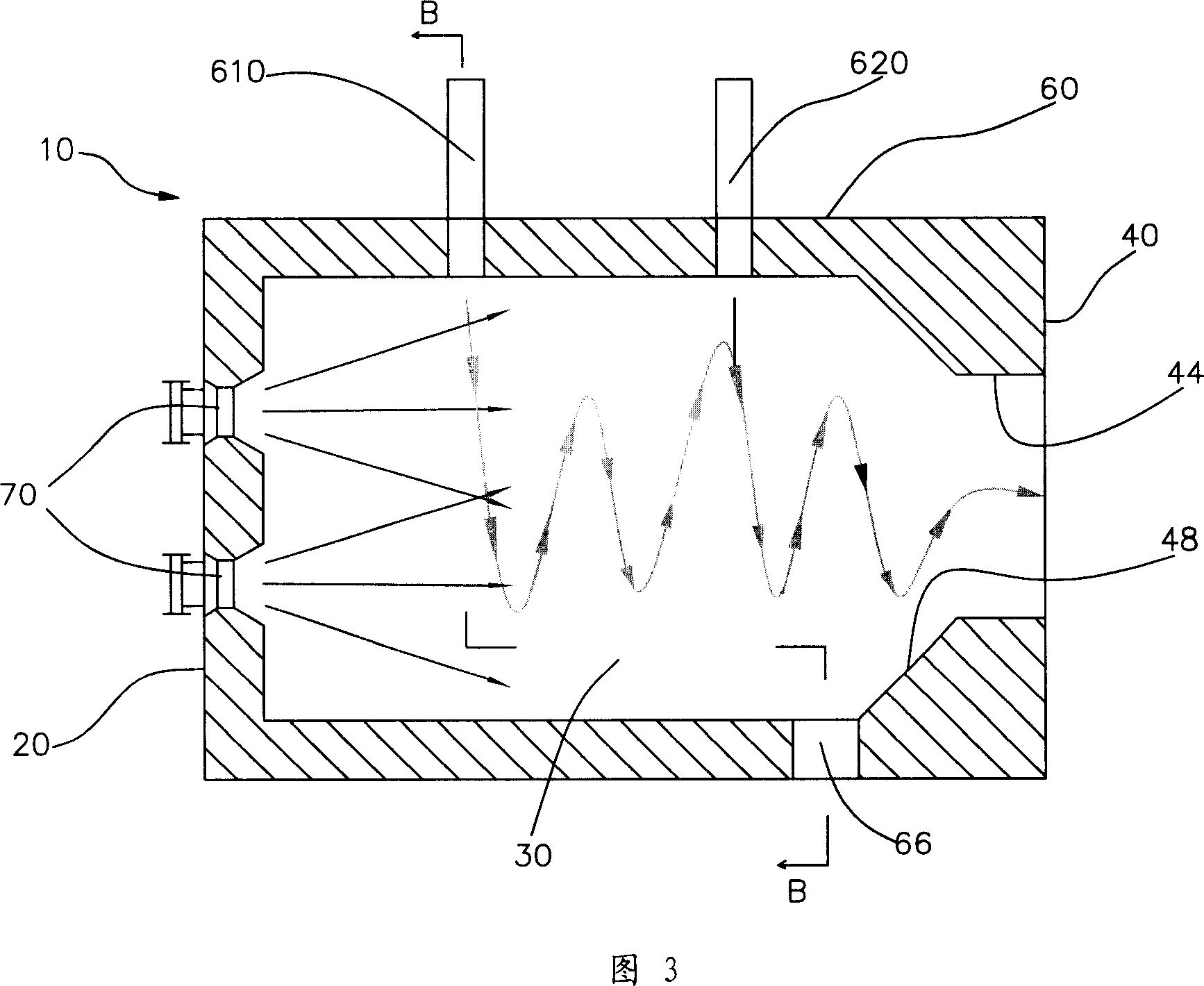

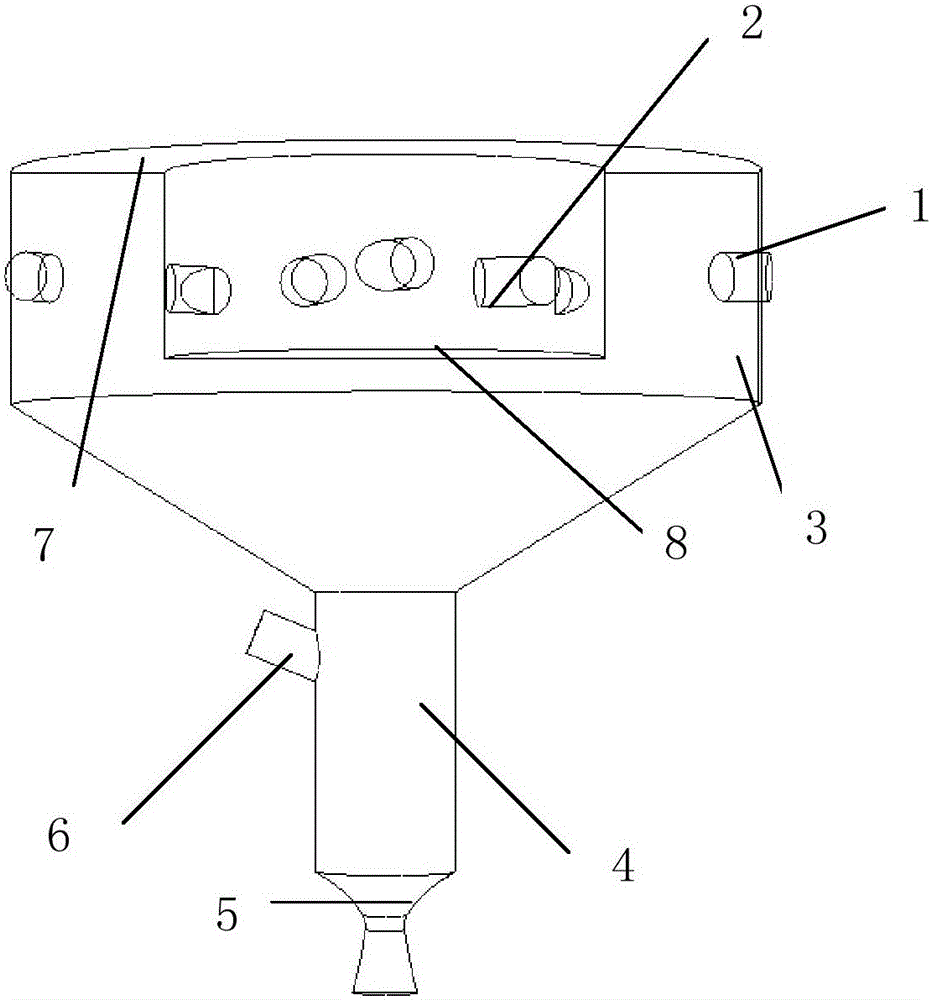

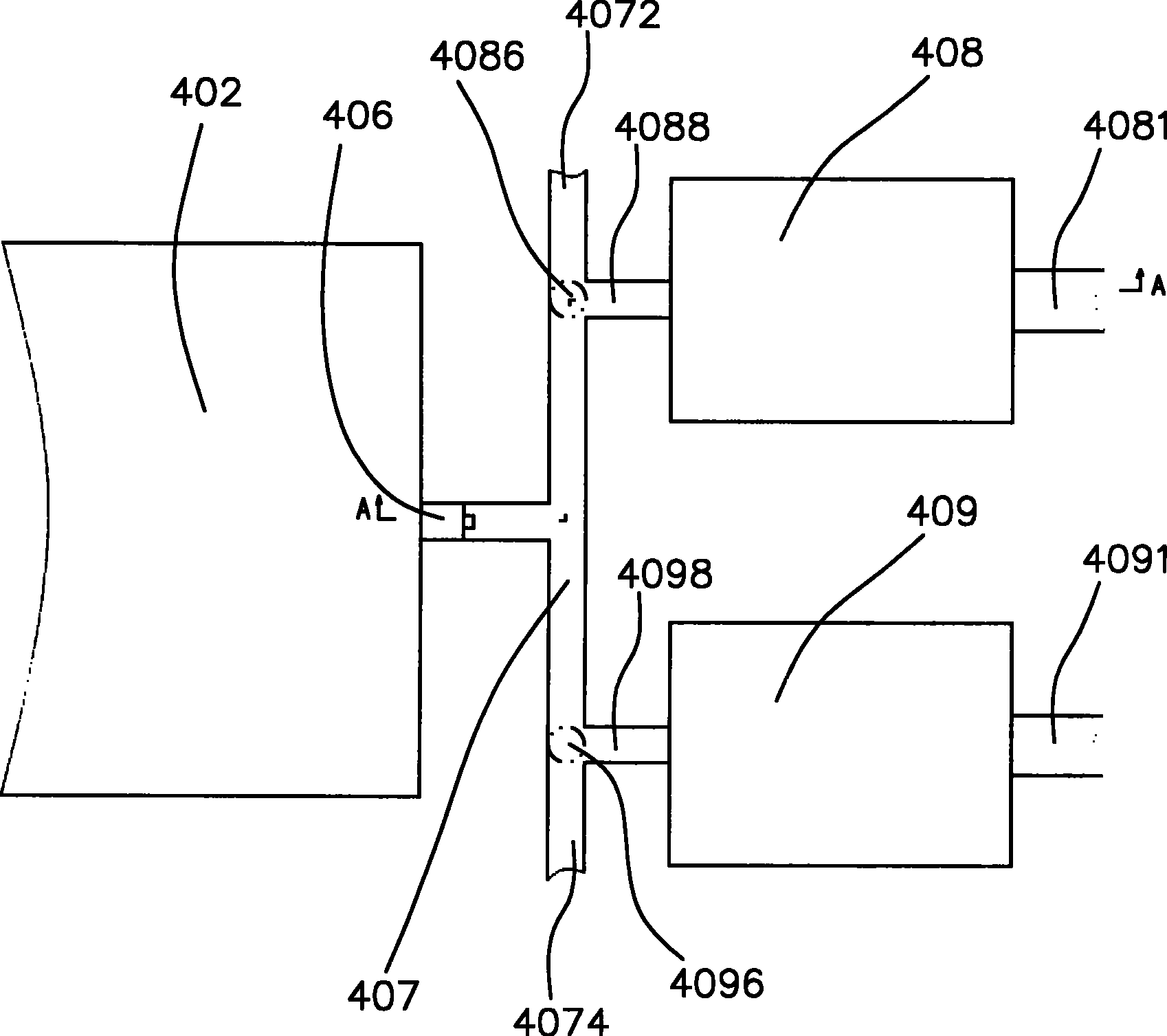

Swirl combustion device for metal and water reaction

InactiveCN104047759AImprove combustion characteristicsIncrease outlet mass flowRam jet enginesCombustion chamberEngineering

The invention provides a swirl combustion device for metal and water reaction. The swirl combustion device for metal and water reaction comprises a combustion chamber, wherein the upper portion of the combustion chamber is an annular container, and the lower portion of the combustion chamber is a conical container. The annular container comprises an outer wall, an inner wall, an upper cover and a bottom cover, wherein the upper cover is used for connecting the inner wall and the outer wall, and the bottom cover is surrounded by the inner wall. A metal spray nozzle is arranged on the outer wall of the annular container, a water spray nozzle is arranged on the inner wall of the annular container, the position of the water spray nozzle corresponds to that of the metal spray nozzle, the upper portion of the conical container is in butt joint with the lower end of the outer wall of the annular container, and the bottom of the conical container is connected with a spray pipe. The swirl combustion device for metal and water reaction is simple in structure and reliable and can overcome the defect that because a compact oxidation film is formed on the surface of metal, combustion is affected; the diameter of molten metal liquid drops can be continuously reduced through shear force of swirls, the surface of unreacted metal is exposed so that the metal can react with water, and thus the metal and water reaction can go on stably, and the combustion efficiency of metal is improved.

Owner:HARBIN ENG UNIV

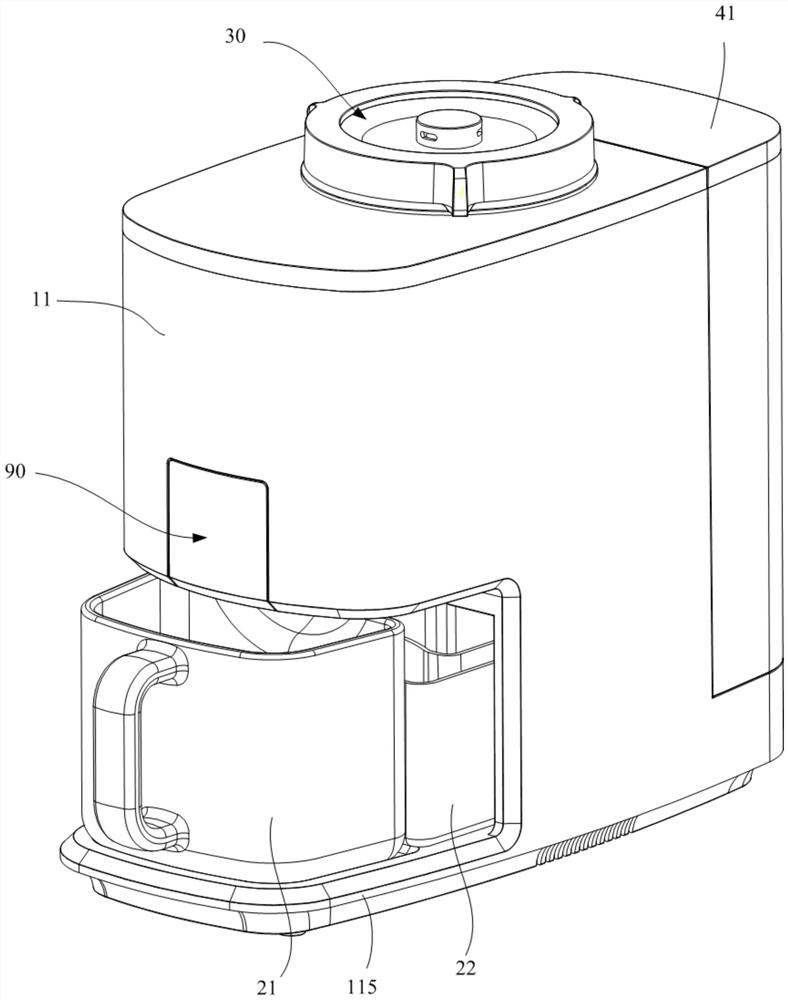

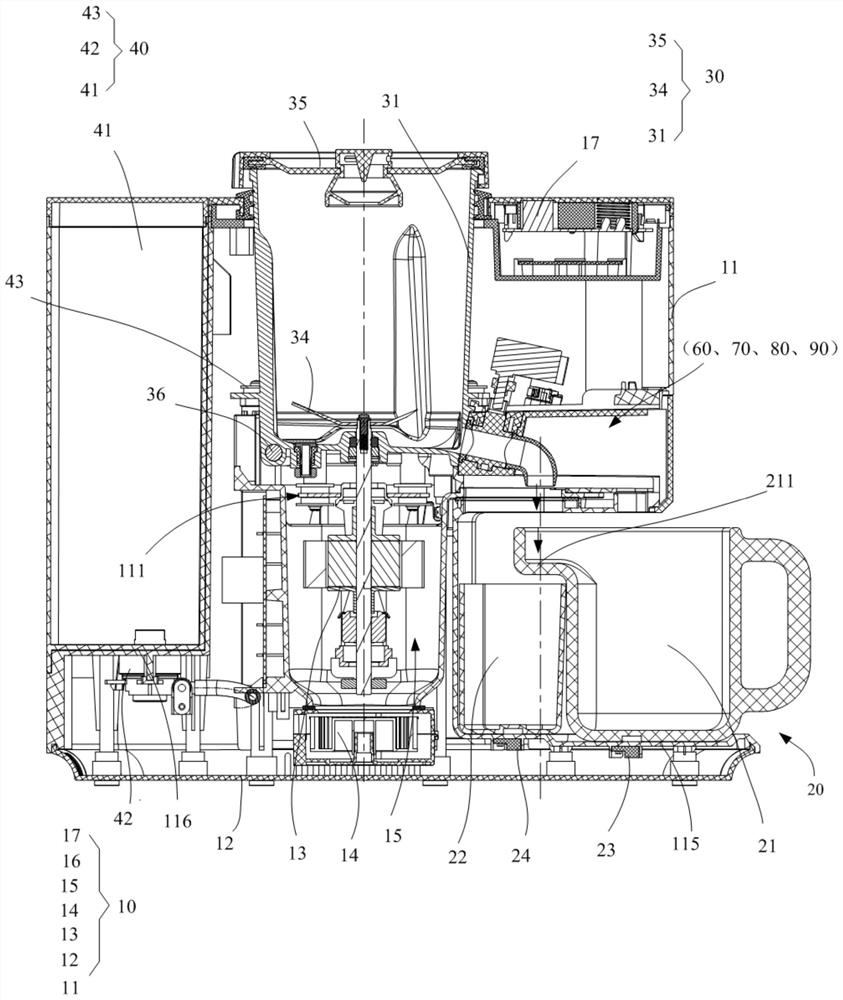

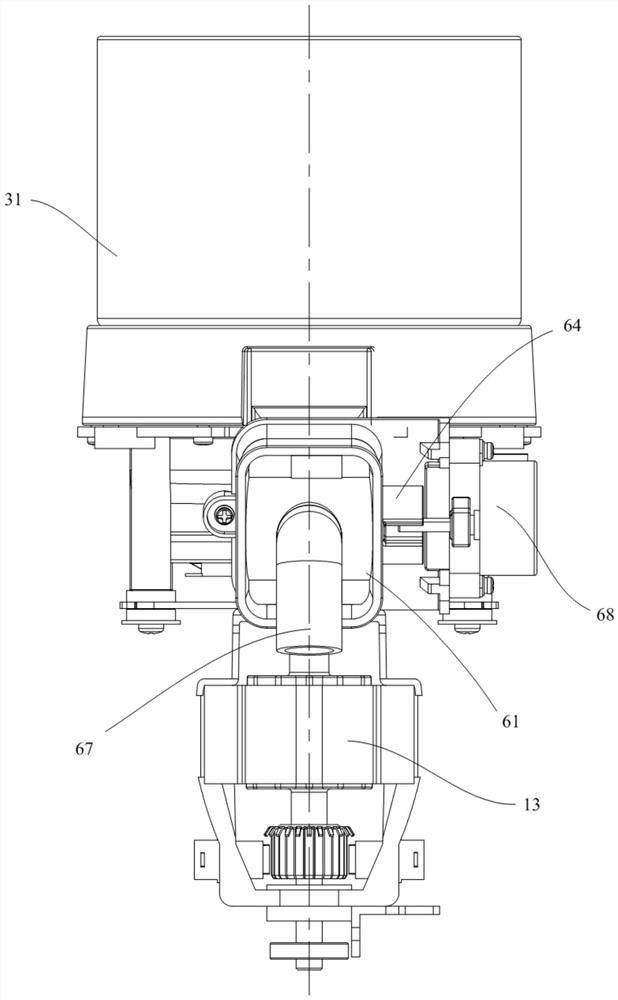

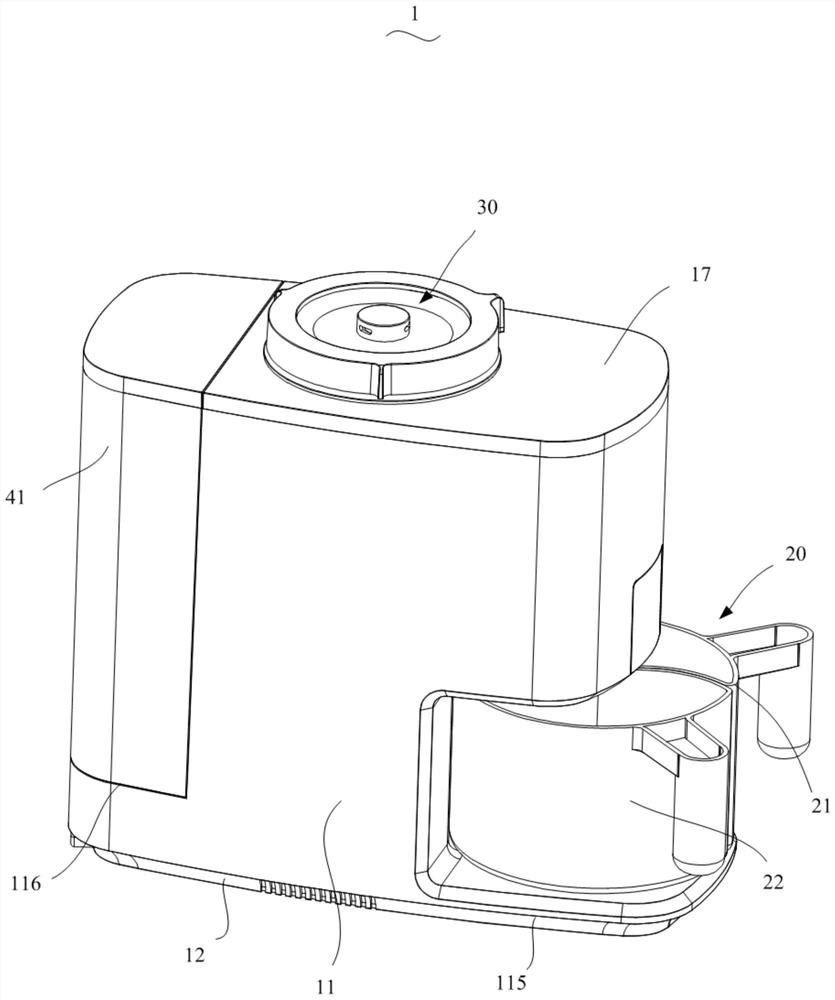

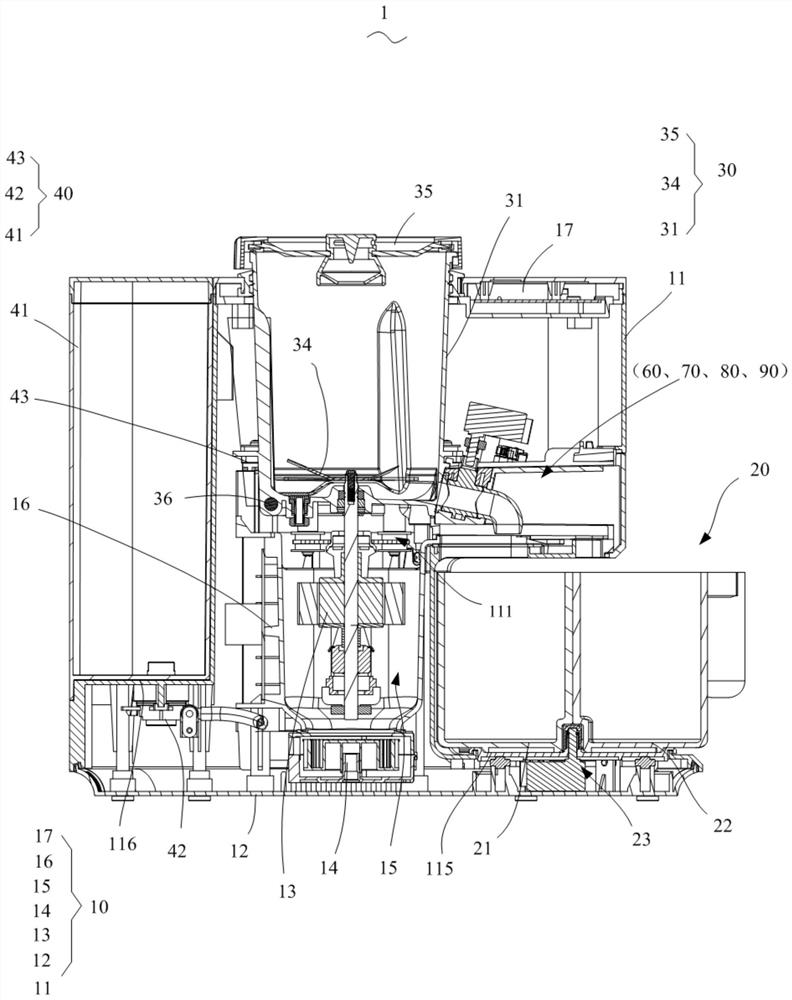

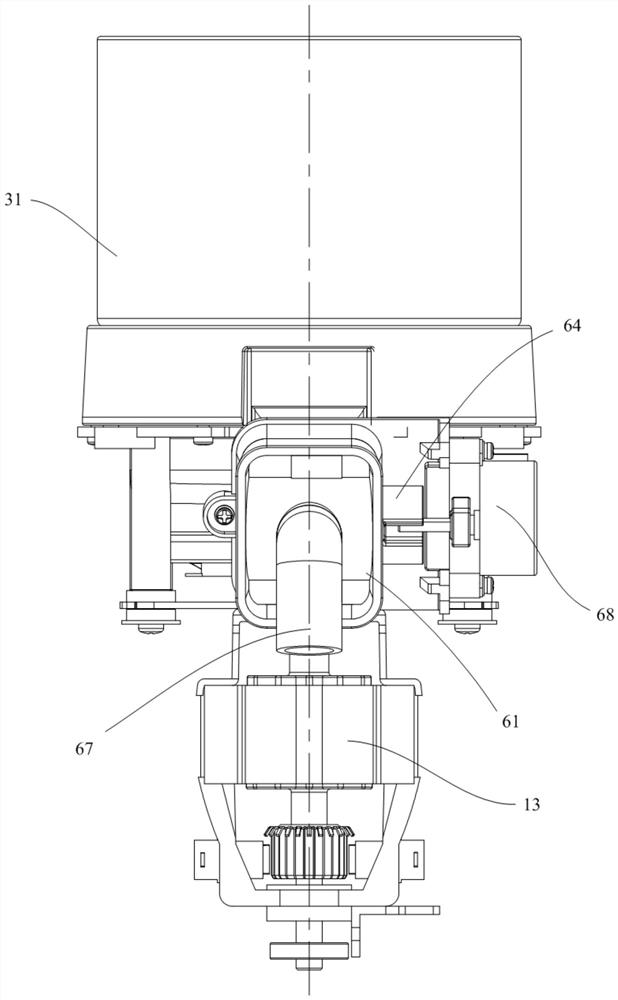

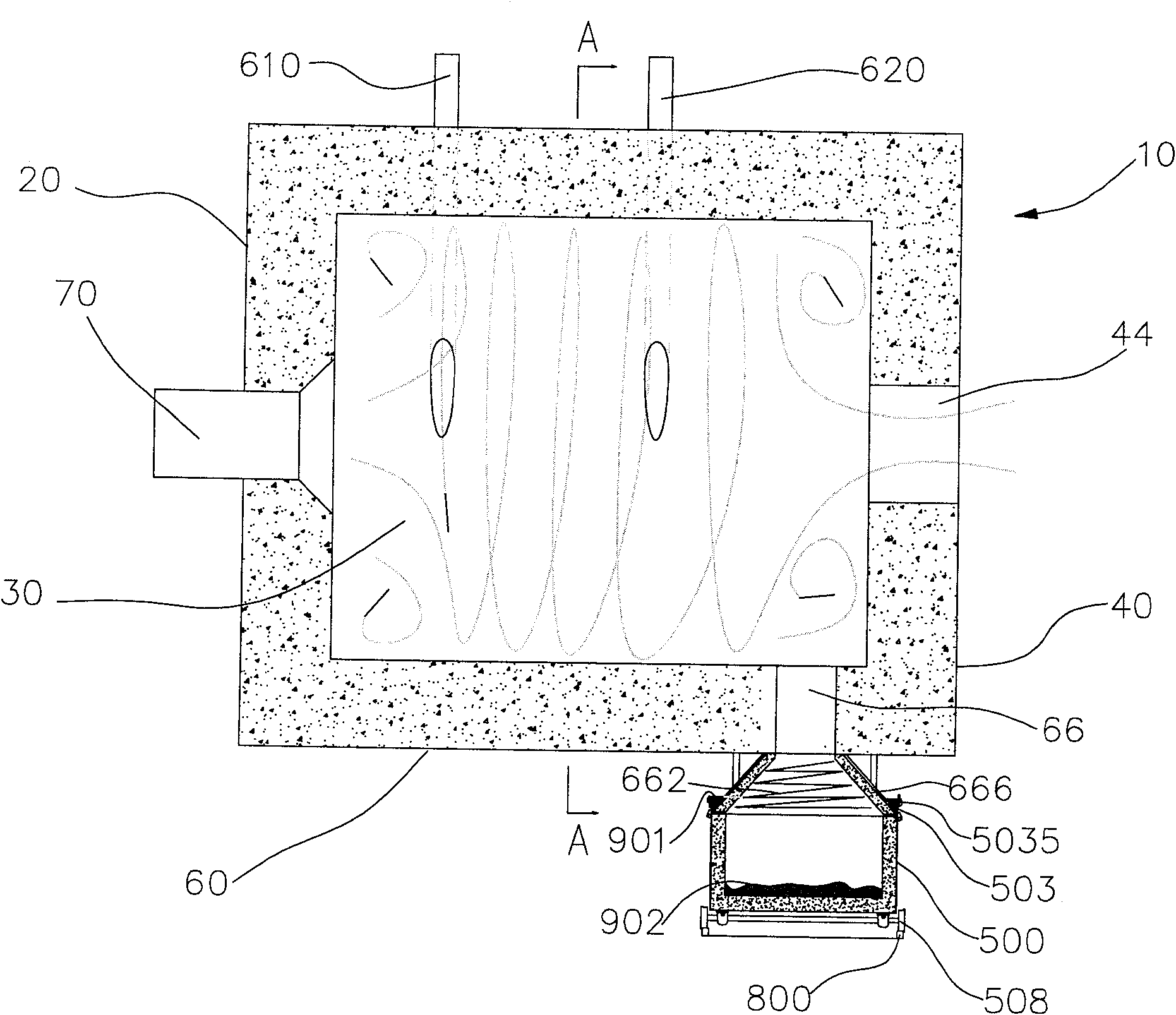

Food processor

The invention discloses a food processor which comprises a main machine, a stirring cup assembly, a slurry discharging valve device and a liquid receiving container assembly, the stirring cup assembly is installed on the main machine, a discharging hole is formed in the stirring cup assembly, and the slurry discharging valve device is installed on the stirring cup assembly and opens or closes the discharging hole; the liquid receiving container assembly is located below the slurry discharging valve device, the liquid receiving container assembly at least comprises a first cup body and a second cup body, and at least part of a cup opening of the first cup body and at least part of a cup opening of the second cup body are overlapped up and down in a falling path of slurry discharged by the slurry discharging valve device. The food processor is convenient to automatically clean.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD

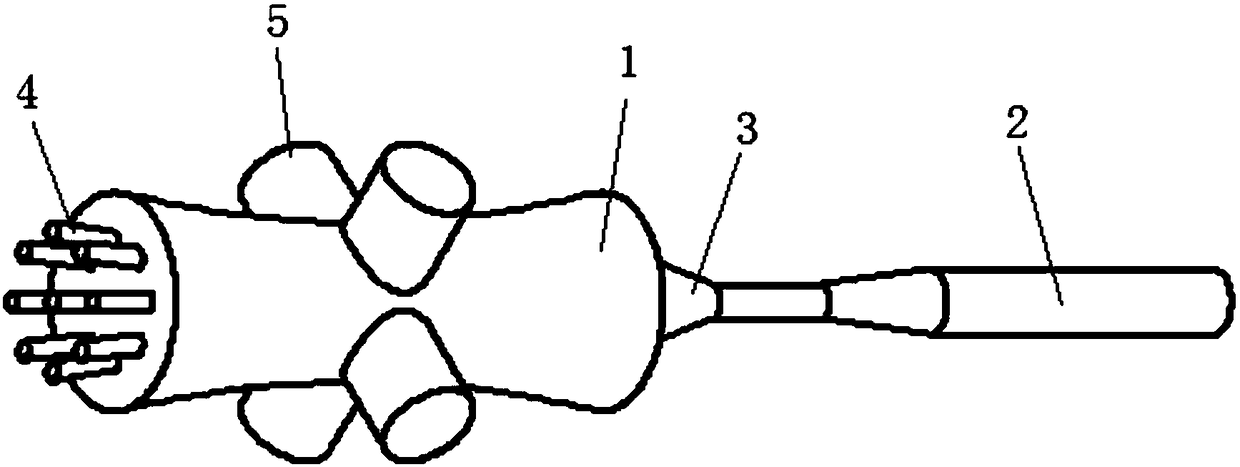

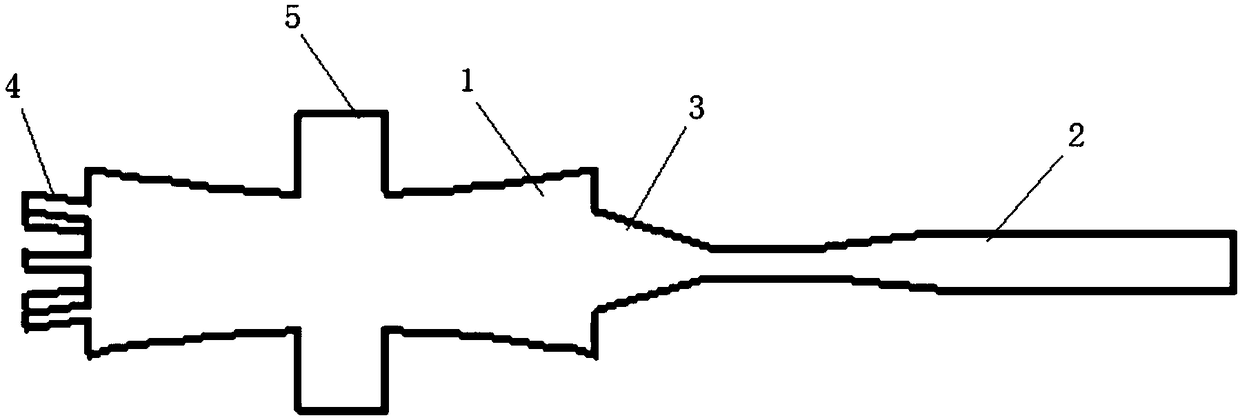

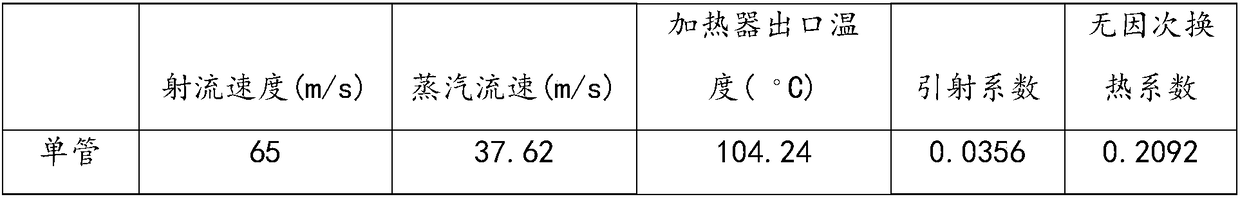

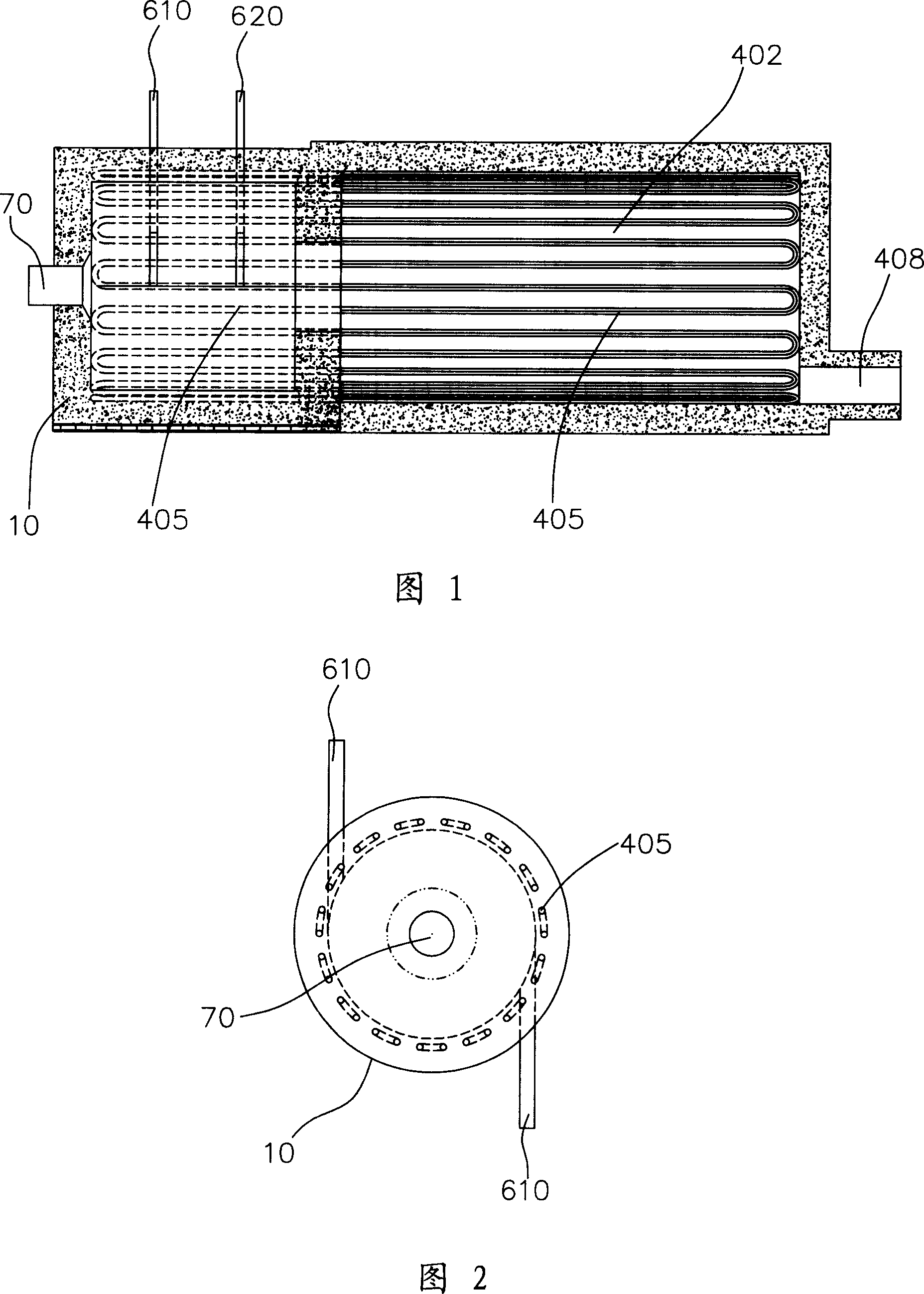

Combined jet ejection type steam-water hybrid heating device

PendingCN108267030AIncrease temperatureImprove performanceDirect contact heat exchangersCondensed waterDiffusion chamber

The invention discloses a combined jet ejection type steam-water hybrid heating device suitable for a low-pressure working condition. The device comprises a zooming arc-shaped mixing chamber, a diffusion chamber, a steam-water mixing reinforcement chamber, a plurality of condensed water ejection type inlets and at least two steam inlets, wherein one end face of the zooming arc-shaped mixing chamber is connected with one end face of the steam-water mixing reinforcement chamber in a coaxial way, and the other end face of the steam-water mixing reinforcement chamber is connected with the diffusion chamber in a coaxial way; the plurality of condensed water ejection type inlets are connected with the other end face of the zooming arc-shaped mixing chamber; the pipe wall of the throat part of the zooming arc-shaped mixing chamber is connected with the at least two steam inlets. The ratio of the end face diameter to the tube length of the zooming arc-shaped mixing chamber is equal to 0.2-0.5;the ratio of the total cross-sectional area of the plurality of condensed water ejection type inlets to the cross-sectional area of a throat pipe of the steam-water mixing reinforcement chamber is equal to 0.008-0.02; the ratio of the total cross-sectional area of the plurality of condensed water ejection type inlets to the total cross-sectional area of the steam inlets is equal to 0.03-0.07; theratio of the cross-sectional area of the throat part of the steam-water mixing reinforcement chamber to the cross-sectional area of an outlet of the diffusion chamber is equal to 2-5; the ratio of the diameter of the throat part to the diameter of the end face of the zooming arc-shaped mixing chamber is equal to 0.50-0.99.

Owner:CHONGQING UNIV

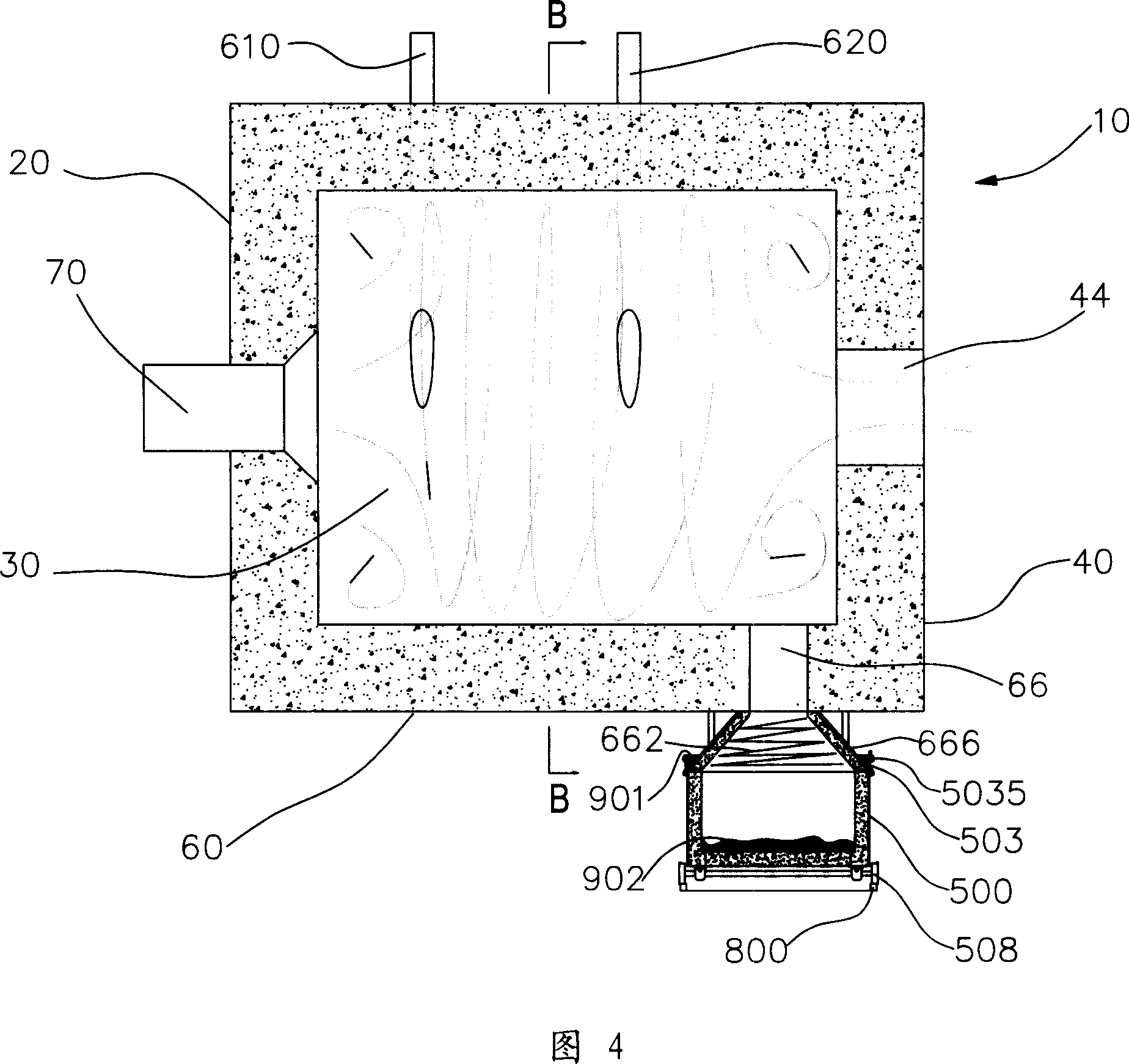

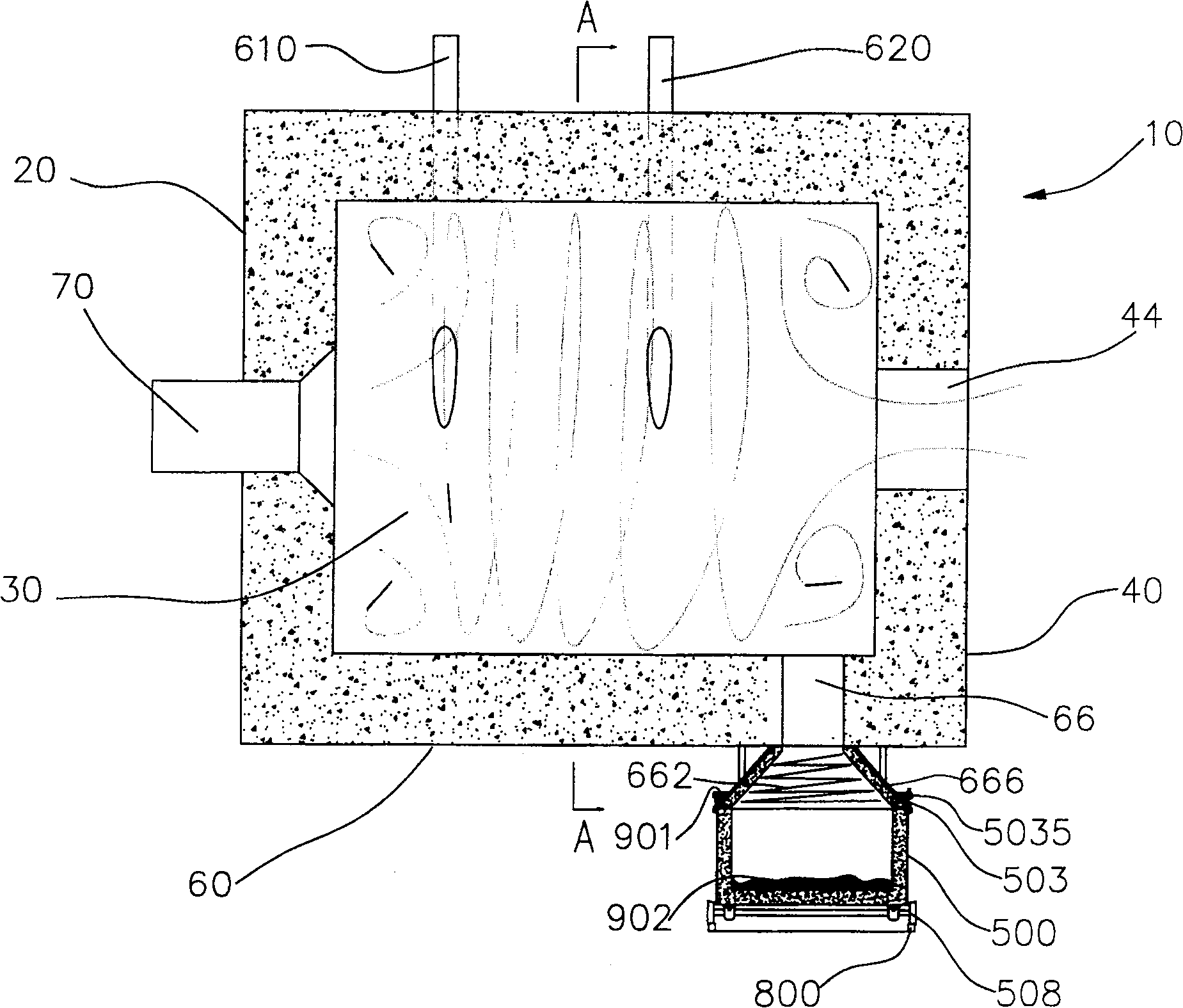

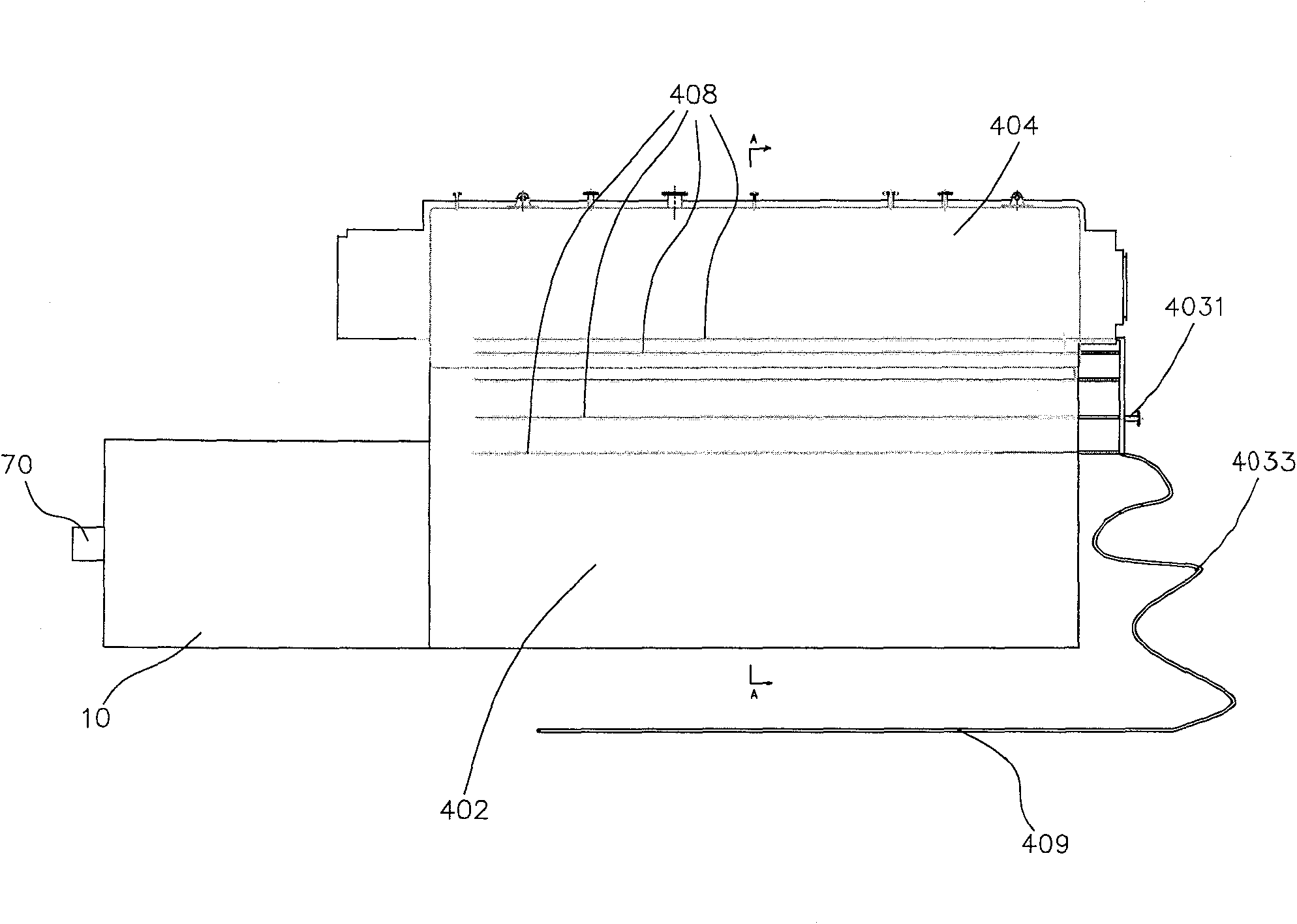

Industrial boiler using emulsifying coke mortar burning device

InactiveCN101021326AEfficient and stable combustionContinuous effective liquid slag removalCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSlurryEngineering

The present invention discloses an industrial boiler adopting emulsified coke slurry combustion equipment. It includes boiler self-body and emulsified coke slurry combustion equipment. The boiler self-body includes furnace cavity, boiler barrel set over the furnace cavity, water pipe which is set in the upper portion of said furnace cavity and is adjacent to the side wall of furnace cavity and fire pipe which is set in the central zone of boiler barrel and is soaked in the water of boiler barrel interior. Said emulsified coke slurry combustion equipment includes a shell body formed from front end wall, rear end wall and side wall, in said shell body interior a cylindrical combustion space is formed, on the front end wall are set at least one emulsified coke slurry combustor, at least one oil combustor and / or at least one gas combustor and on the rear end wall an outlet is cut, said outlet is communicated with the furnace cavity. Said invention also provides the working principle of said industrial boiler and its concrete operation method.

Owner:广州迪森热能设备有限公司

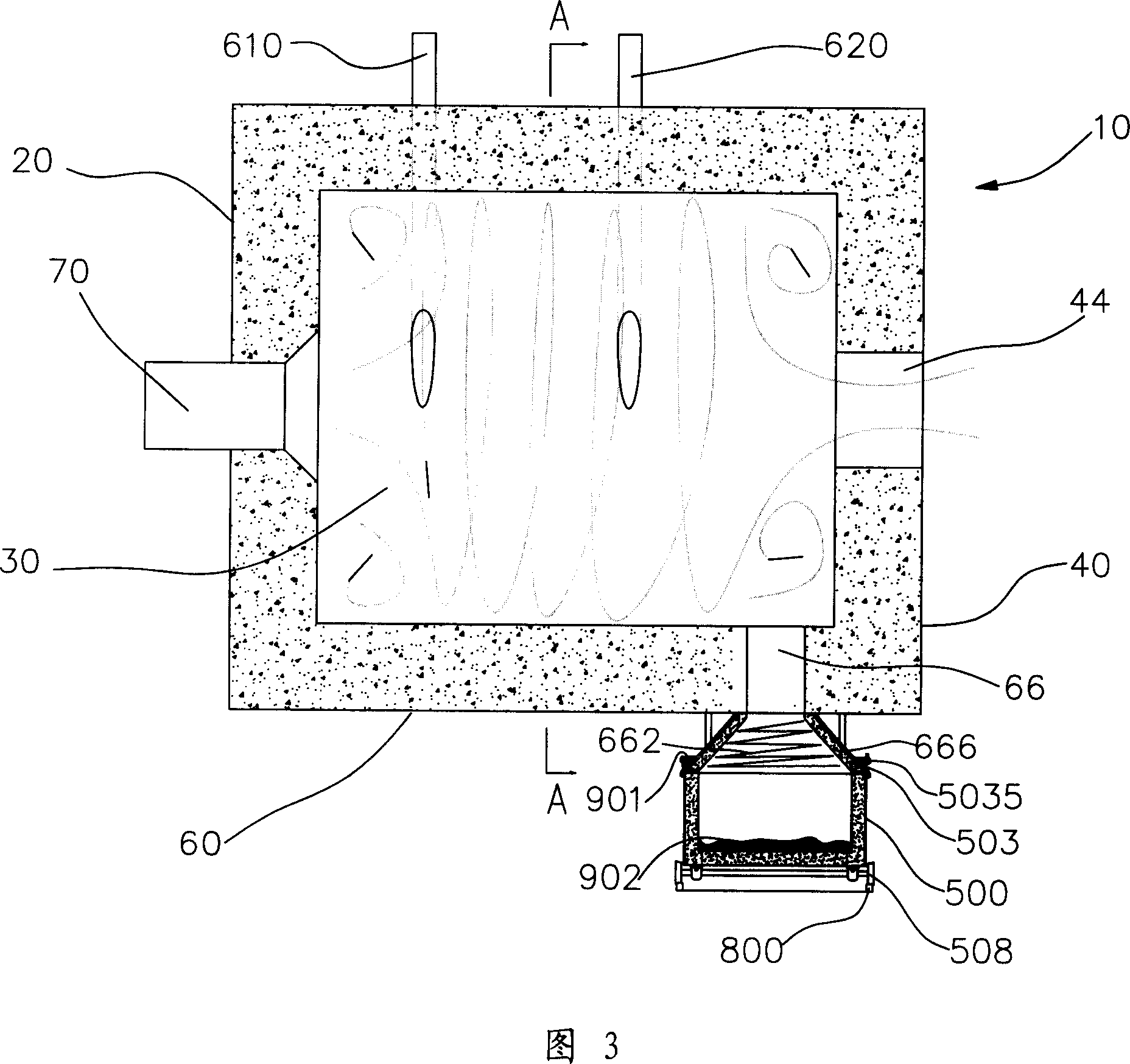

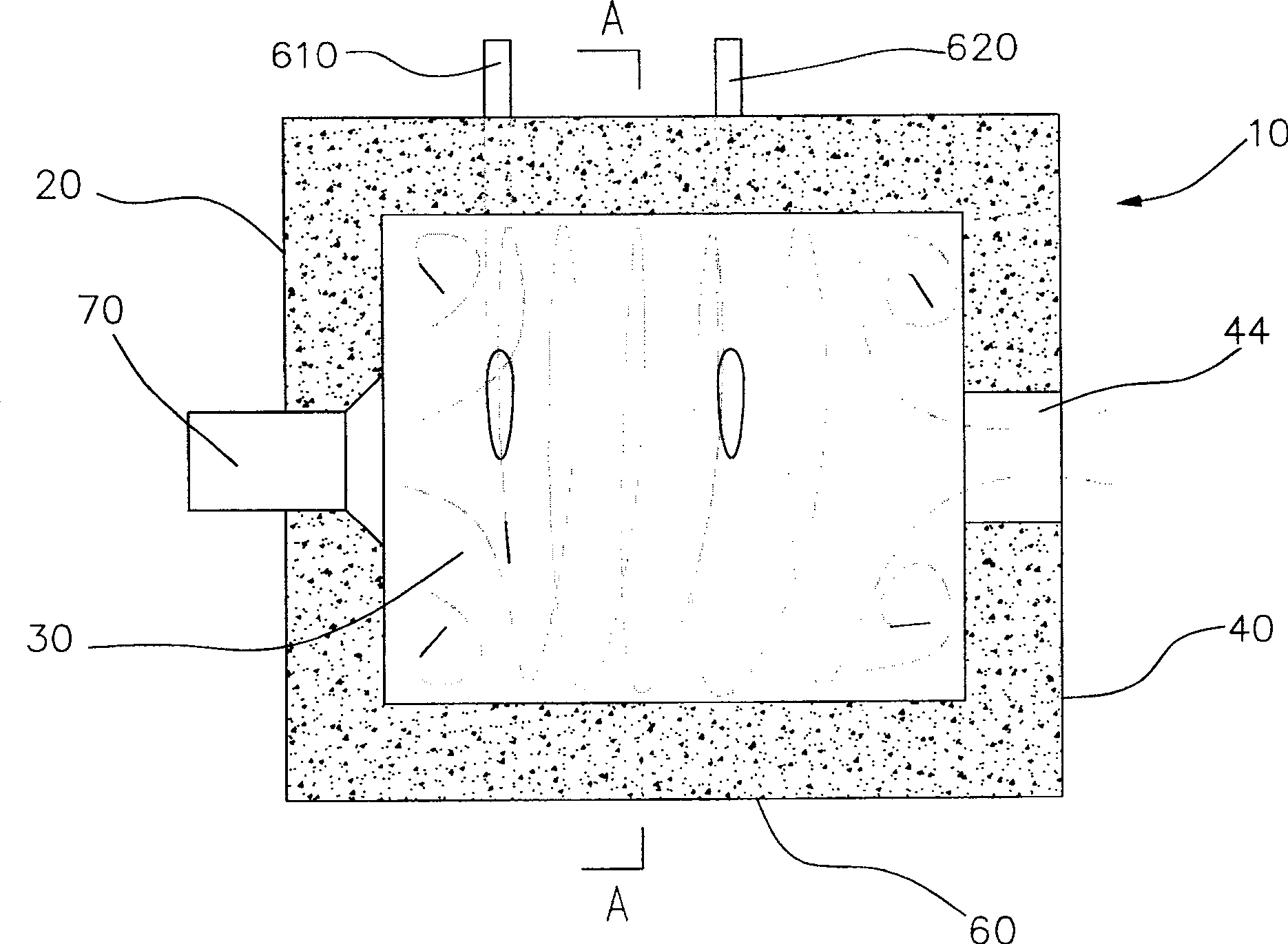

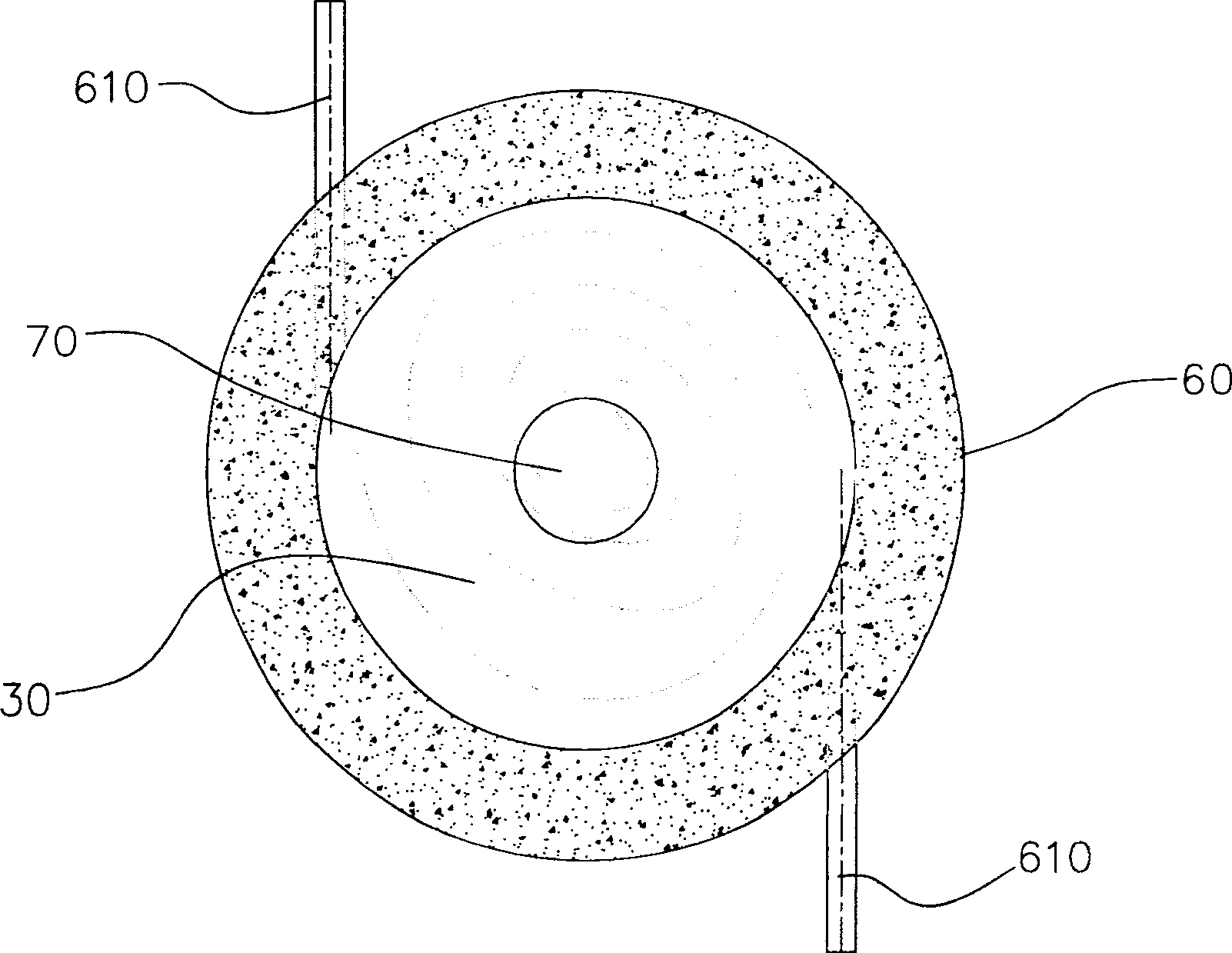

Device for interactive reaction between heavy metals and particulate matter and reaction method

InactiveCN106540506AWell mixedMix vigorouslyGas treatmentDispersed particle separationPeristaltic pumpAdditive ingredient

The invention discloses a device for interactive reaction between heavy metals and particulate matter and belongs to the field of interactive reaction devices. The device comprises a flue gas mixing system, a temperature control hearth and a tail gas processing system, wherein a temperature control device is arranged in the temperature control hearth, an ejector, an atomizer and a sampling hole are respectively arranged outside of the temperature control hearth, the front end of the ejector is connected with one end of the flue gas mixing system and one end of the atomizer respectively, the other end of the atomizer is connected with a peristaltic pump, and the tail end of the temperature control hearth is connected with the tail gas processing system. The device can be used for researching a reaction mechanism of specific ingredients of particulate matter and heavy metals under different conditions in different concentrations of heavy metal atmospheres, and the peristaltic pump combines with an atomizer and double-by-path venturi ejector combined device, so that the particulate matter and the heavy metal atmospheres re evenly mixed, and control is convenient. In addition, feeding is performed from the cylindrical tangent plane of the hearth, so that mixing is violent, and the staying time of fine particulate matter and heavy metal flue gas in the hearth is also prolonged.

Owner:SHENYANG AEROSPACE UNIVERSITY

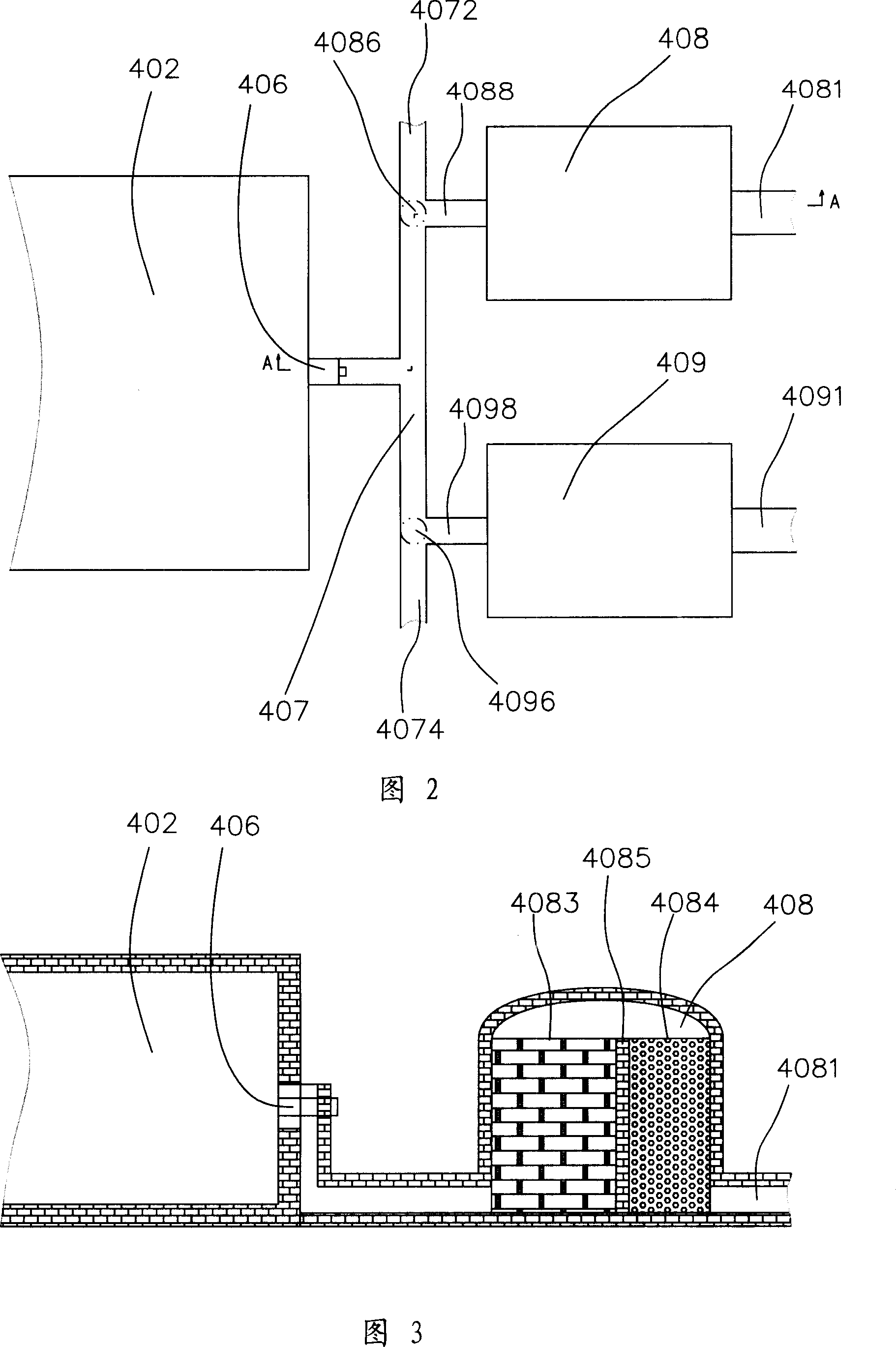

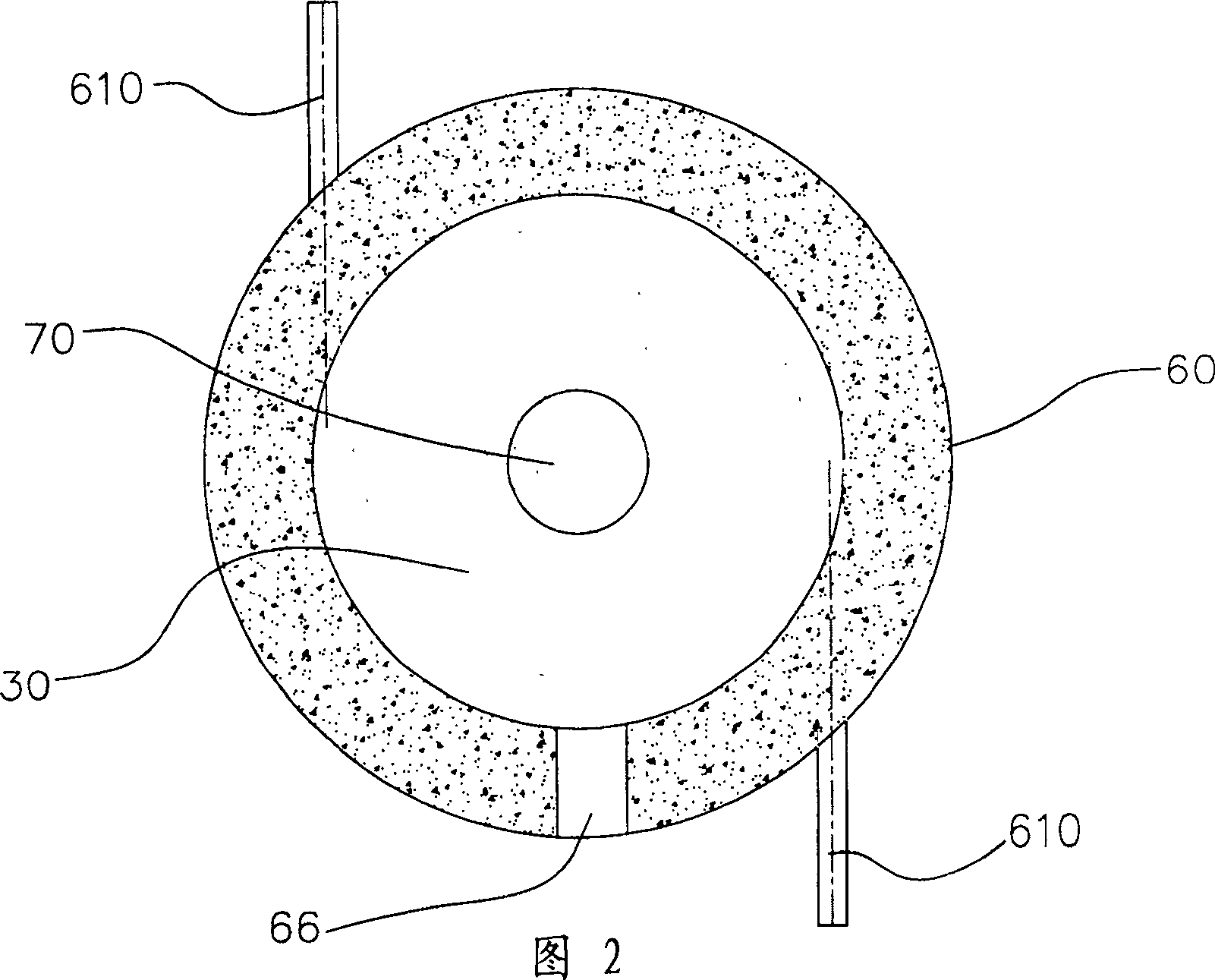

Emusified coking-slurry cyclone burner

InactiveCN101029729AAvoid fouling and cokingReduce generationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneFlue gas

This invention discloses an emulsification burning device that consists of a front end wall, back end wall and the side crust inside which forms a cylindraceous burning space. There are at least one emulsification burning device and at least a fuel burning device or at least air burning device. The side of the crust sets two or more tangential wind inlet openings each of which includes two or more tangential wind inlet openings which can make the tangential wind inside the burning space form circumfluence along the side of the crust. There are at least one dreg outlet opening near the back end wall at the side of the bottom of the burning space. The cross section of the dreg outlet opening lies between the cross section of the tangential wind inlet opening near the back end wall and the inside of the back end wall. The emulsification burning device of this invention can realize the liquid slag avoiding the deposition and coking of the flue gases on the heating surface.

Owner:GUANGZHOU DEVOTION THERMAL TECH

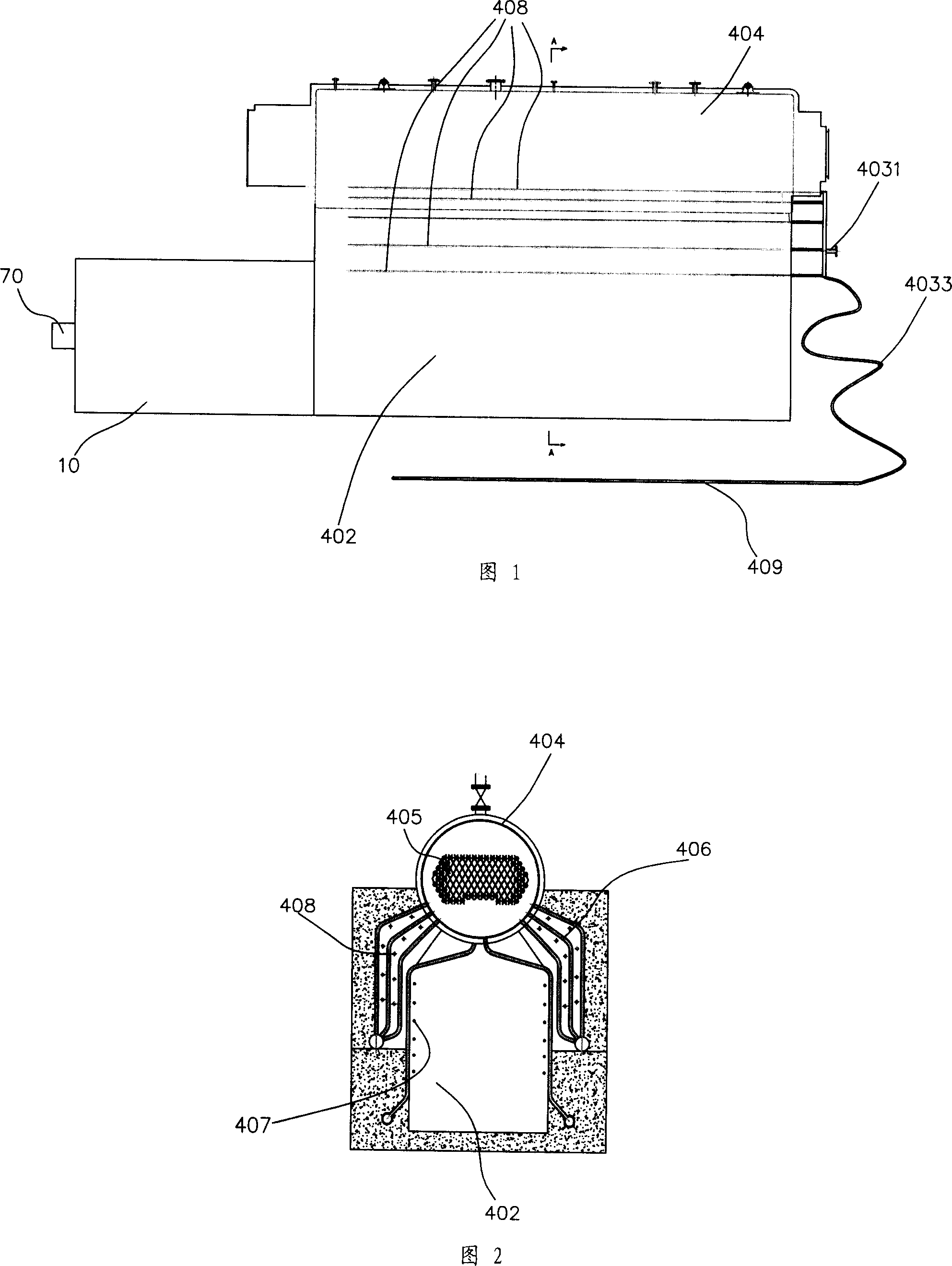

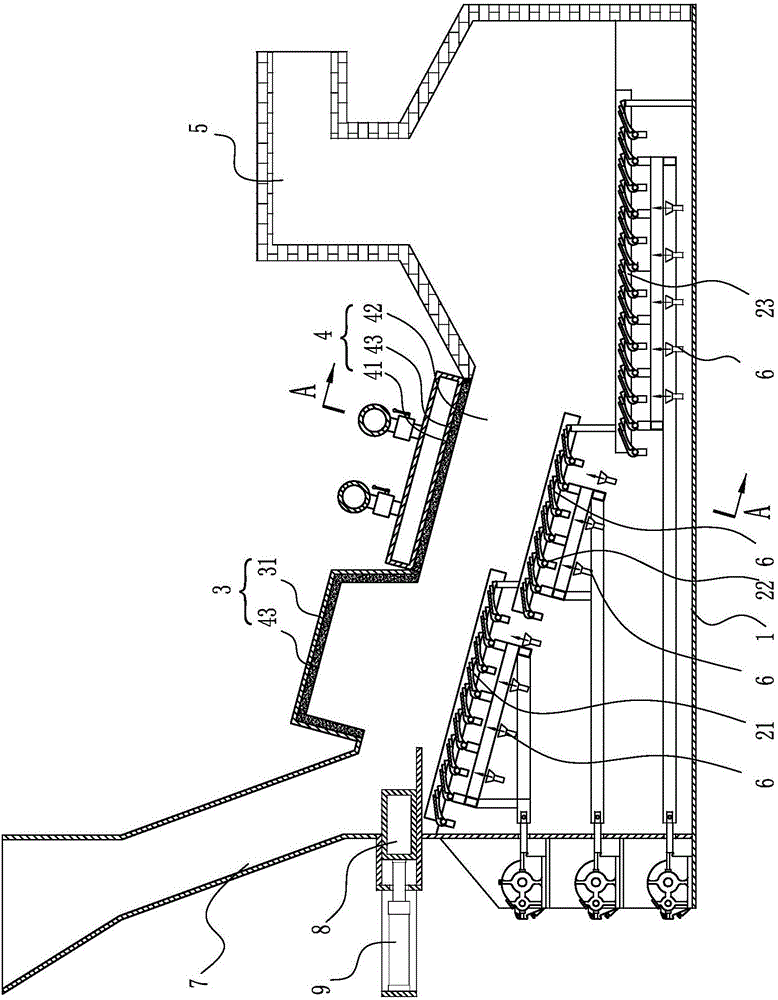

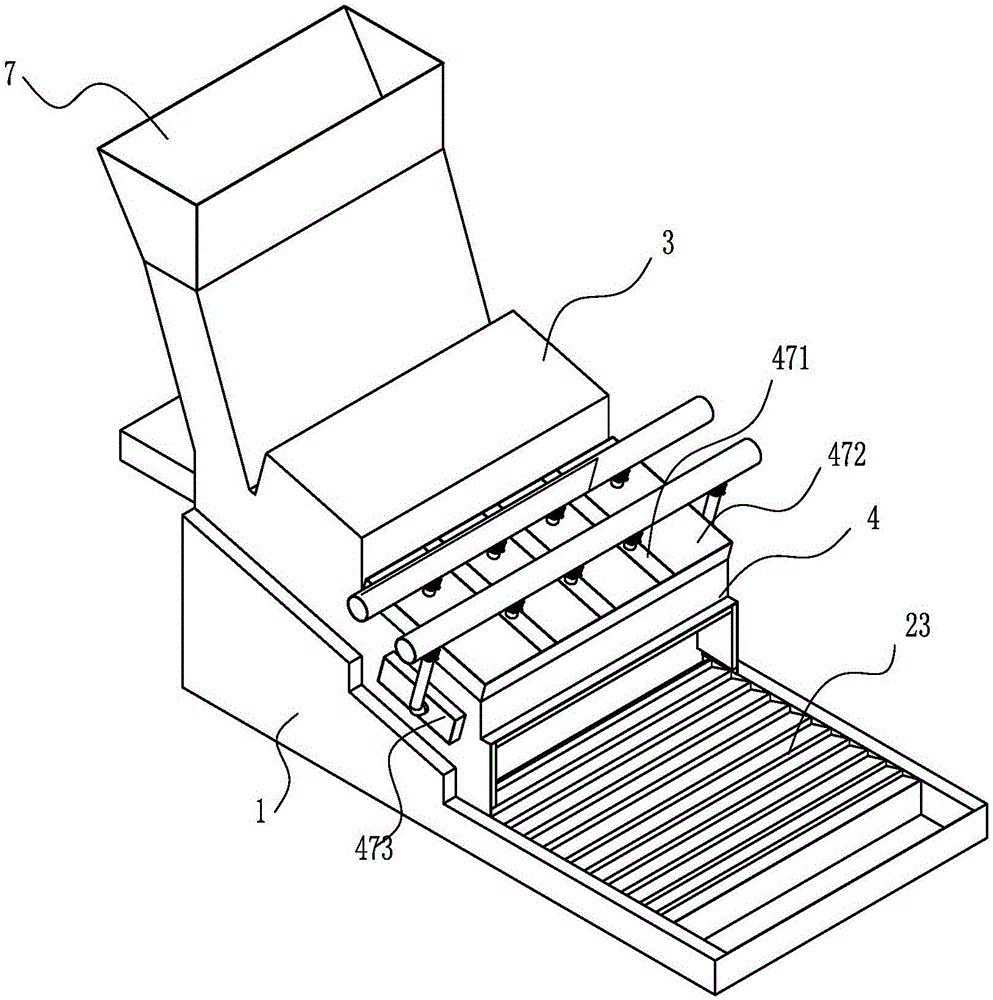

Large-capacity garbage high-temperature gasification spraying combustion system

ActiveCN106765123ARelease fullyWell mixedIncinerator apparatusCombined combustion mitigationSocial benefitsCombustion system

The invention discloses a large-capacity garbage high-temperature gasification spraying combustion system comprising a furnace body base. A drying section furnace body and a spraying combustion section furnace body are arranged on the furnace body base. The spraying combustion section furnace body comprises a spraying combustion main furnace body. A spraying combustion rotational flow hearth is arranged in the spraying combustion main furnace body. Spraying combustion top spraying openings embedded in a fireproof material layer are formed in the top wall of the spraying combustion rotational flow hearth, and spraying combustion outer side spraying openings embedded in the fireproof material layer are formed in the side wall of the spraying combustion rotational flow hearth. The spraying combustion top spraying openings and the spraying combustion outer side spraying openings are formed in the spraying combustion rotational flow hearth, so that two combustion vortexes are formed in the spraying combustion rotational flow hearth, particles and components which are incomplete in gasification combustion are mixed and combusted fully, the temperature of the combustion vortexes can reach 1200-1300 DEG C, dioxin is also decomposed completely at the stage, and combustion is more fierce; and the large-capacity garbage high-temperature gasification spraying combustion system is a breakthrough technological progress of the garbage incineration technology and has great economic benefits and social benefits.

Owner:刘振亮

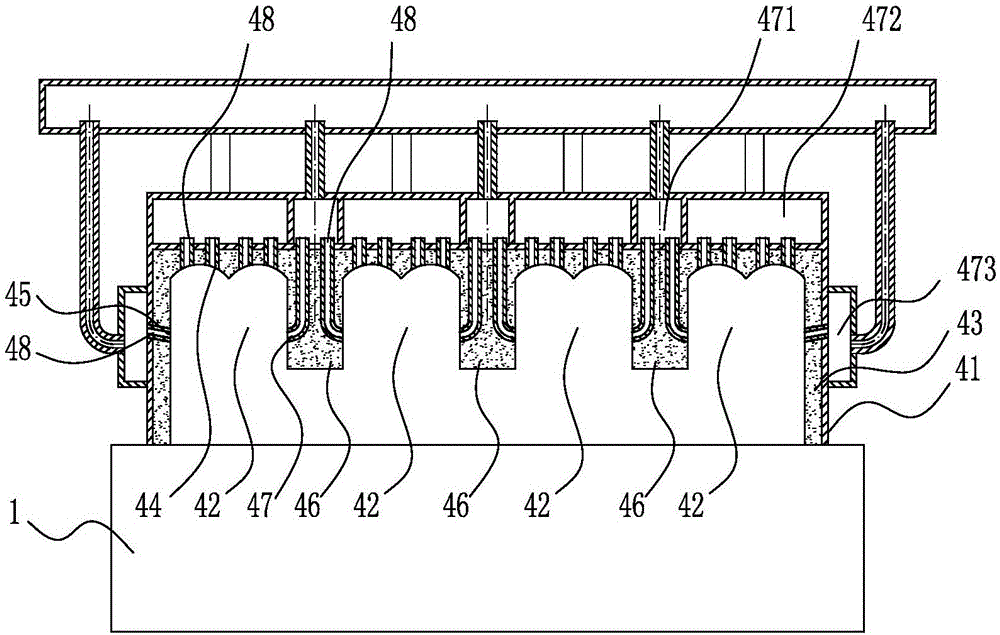

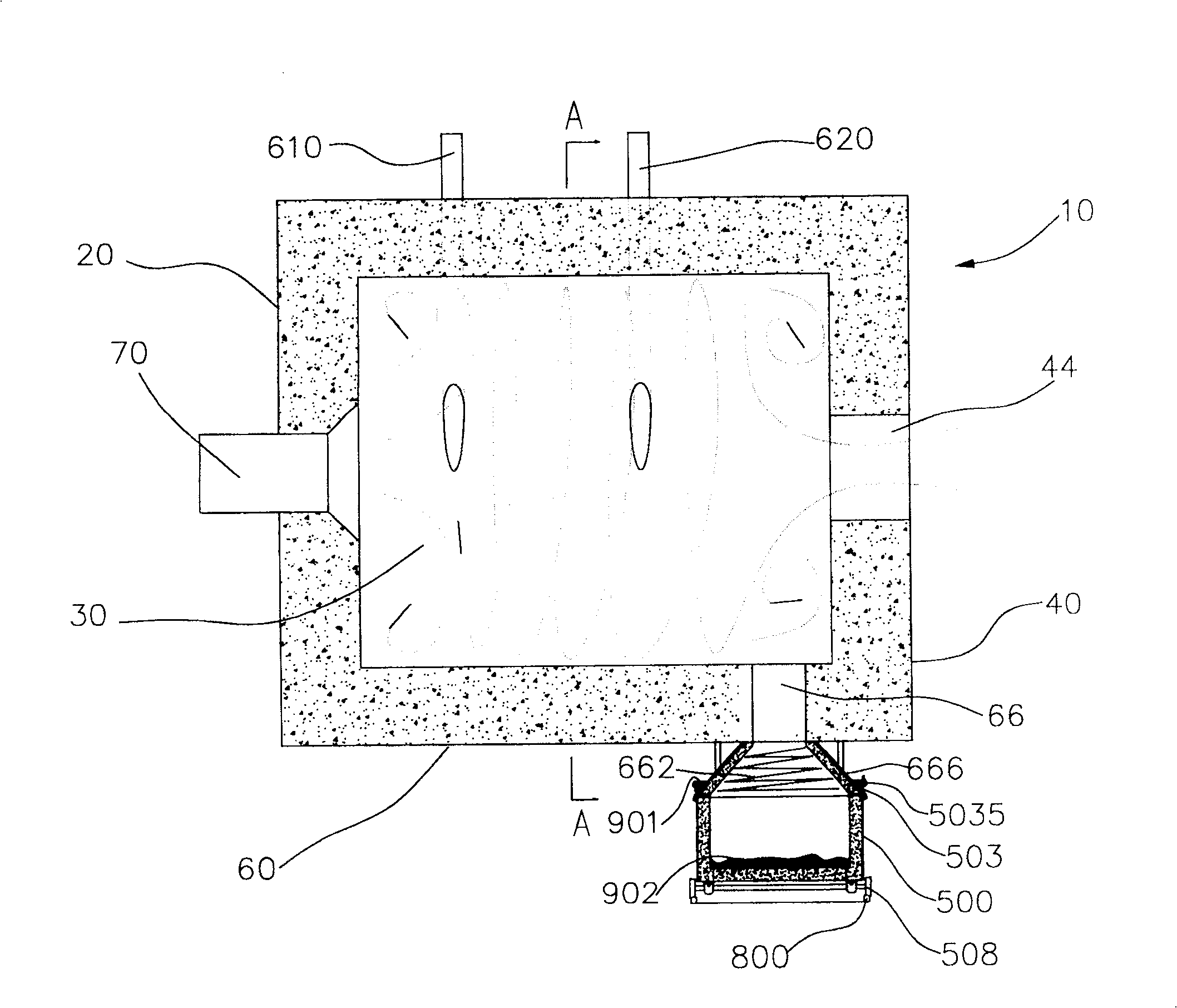

Environment-friendly clay stabilizer for oil well fracturing as well as preparation device and preparation method

ActiveCN111205849AInhibit swellingInhibit migrationChemical/physical/physico-chemical stationary reactorsDrilling compositionPhysical chemistryDioxyethylene Ether

The invention discloses an environment-friendly clay stabilizer for oil well fracturing as well as a preparation method and special preparation equipment of the environment-friendly clay stabilizer. The clay stabilizer comprises the following components in parts by weight: 15-25 parts of calcium chloride dihydrate, 4-12 parts of a fatty alcohol, 2-10 parts of an alkyl polyoxyethylene ether, 4-12 parts of sodium dodecyl benzene sulfonate and 10-30 parts of methanol. The preparation method is realized on the basis of preparation equipment, a lower feed liquid and an upper feed liquid in a reaction kettle are mixed alternately, and a stirring mechanism is driven to rotate eccentrically, so that the stirring range is greatly widened. The preparation method has the characteristics of safety, and environmental friendliness; the mixing time can be saved, and full mixing can be realized by using the preparation equipment. The preparation method is suitable for the technical field of preparation of clay stabilizers.

Owner:海兴县新源化工有限公司

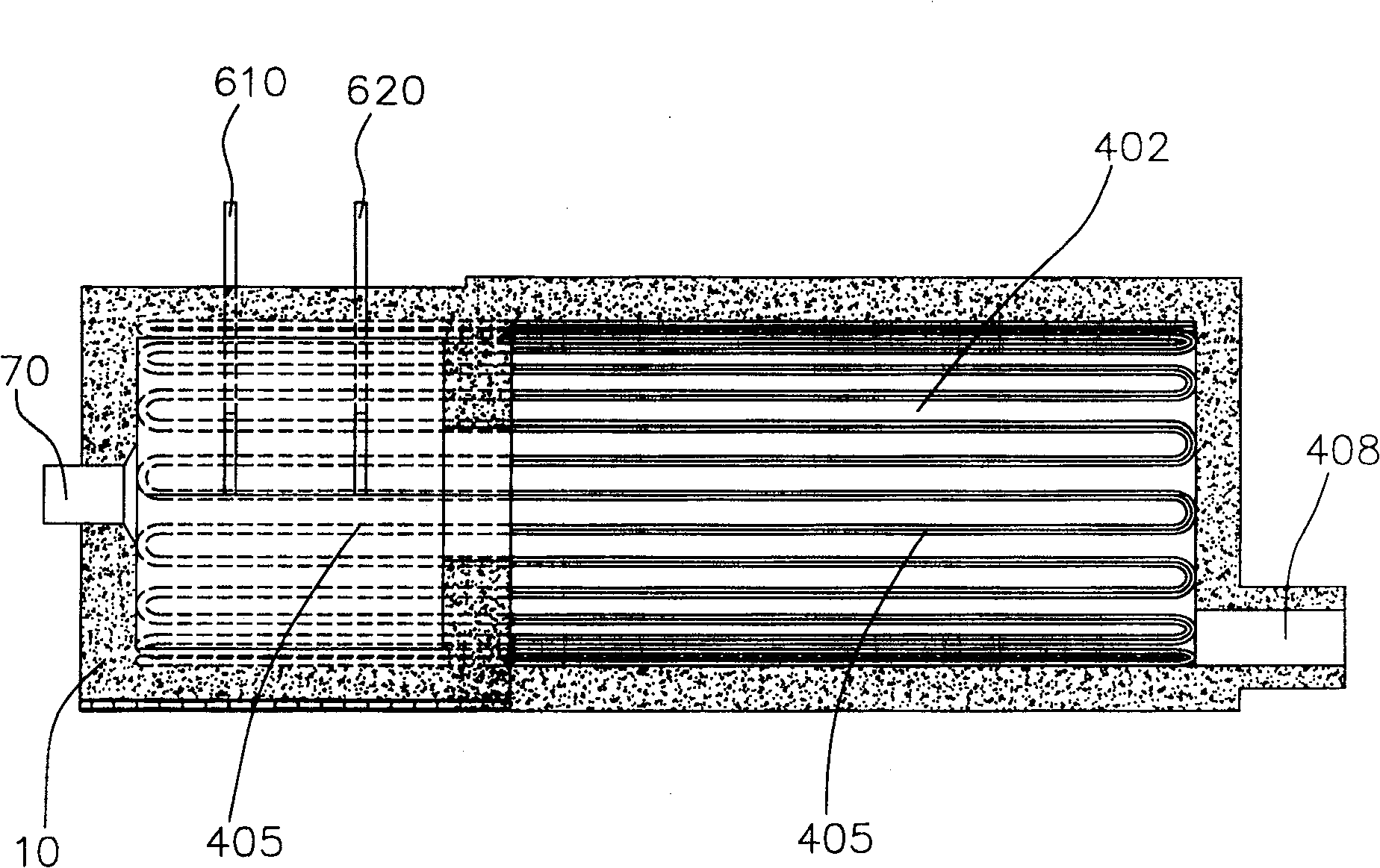

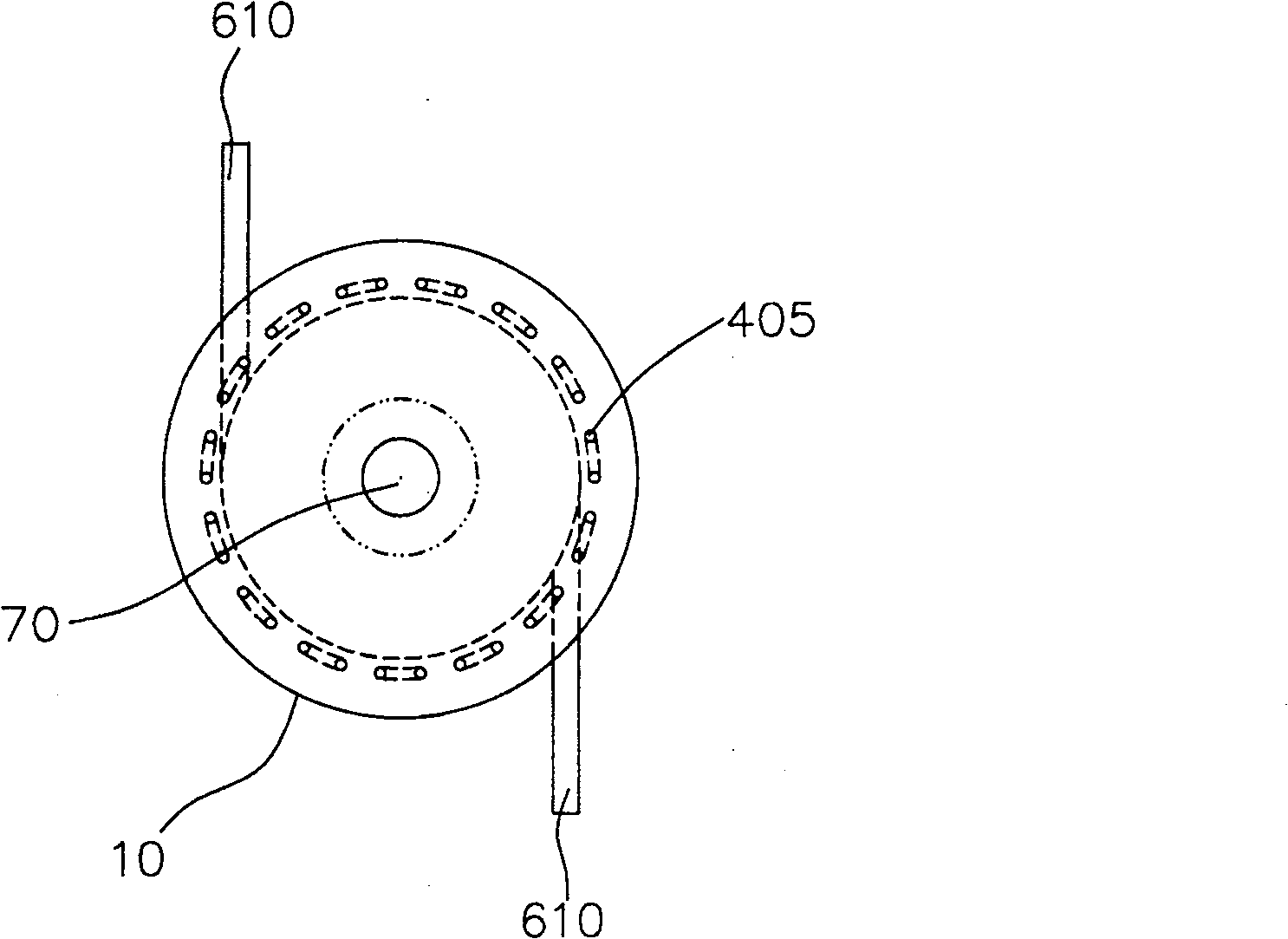

Heat conductive oil furnace using emulsifying coke mortar vortex burning device

InactiveCN101021357AEfficient and stable combustionContinuous effective liquid slag removalCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelHeat conductingLiquid slag

The invention discloses a heat-conducting oil stove used the emulsifying burnt plasma vortex burning device. It includes the oil stove body and the emulsifying burnt plasma vortex burner which includes the shell composed by the front wall, the back wall and the side wall. The burning room is formed in the shell. At least one emulsifying burnt plasma vortex burner and at least one oil burner or at least one gas burner is set in the front wall; an outlet is set in the back wall which is connected with the flame inlet of furnace chamber by the warm-air pipe. The two or above groups of tangential wind inlets are set on the shell side wall alternately; the outlet of the liquid slag is on the side wall of the burning room bottom which is near to the back wall. The invention uses the emulsifying burnt plasma as the fuel, so it can save the cost.

Owner:广州迪森热能设备有限公司

Food processor

The invention discloses a food processor which comprises a main machine and a stirring cup assembly, wherein the stirring cup assembly is installed on the main machine, and a discharging hole is formed in the stirring cup assembly; a thick liquid discharging valve device which is arranged on the stirring cup assembly and is used for opening or closing the discharging hole; a liquid receiving container assembly which is located below the thick liquid discharging valve device, wherein the liquid receiving container assembly at least comprises a first cup body and a second cup body; and a movement driving assembly which drives the first cup body and the second cup body to move, so that one of the first cup body and the second cup body enters a liquid receiving position to receive liquid discharged by the thick liquid discharging valve device. The food processor is convenient to clean.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD

Gas injection boiler using the emulsifying coke mortar combustion device

InactiveCN101021313AEfficient and stable combustionReasonable useCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSlurryEngineering

The present invention discloses a steam-injecting boiler adopting emulsified coke slurry combustion equipment. It includes boiler self-body and emulsified coke slurry combustion equipment. Said boiler self-body includes furnace cavity, at least one steam pipe set in the furnace cavity interior and smoke outlet cut on one end wall far-separated from the emulsified coke slurry combustion equipment. Said emulsified coke slurry combustion equipment includes a shell body formed from front end wall, rear end wall and side wall, a cylindrical combustion space is formed in the shell body, on the front end wall at least one emulsified coke slurry combustor, at least one oil combustor and / or at least one gas combustor are set, its rear end wall is equipped with an outlet, said outlet is communicated with furnace cavity.

Owner:广州迪森热能设备有限公司

Gas inlet device of chloromethane reaction tower

ActiveCN111821921AReduce the amount of processingSimple processFeed devicesElectrical and Electronics engineeringMechanical engineering

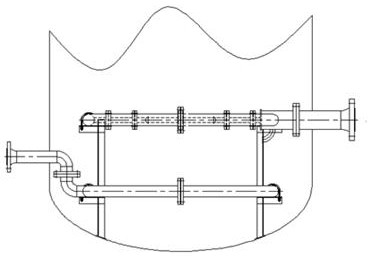

The invention discloses a gas inlet device of a chloromethane reaction tower. The device comprises a tower body, and further comprises: a sealed reaction barrel fixedly connected into the tower body;a gas inlet pipe A, one end of which is fixedly communicated with the upper part of the reaction barrel, and the other end of which stretches out of the tower body; a gas inlet pipe B, one end of which is fixedly communicated with the lower part of the reaction barrel, and the other end of which stretches out of the tower body; a plurality of communicating pipes C, one ends of which are fixedly communicated with the reaction barrel, and the other ends of which are fixedly communicated with the middles of corresponding arc-shaped gas outlet pipes D, wherein the communicating pipes C are locatedbetween the gas inlet pipe A and the gas inlet pipe B and are distributed along the circumference of the reaction barrel, gas outlets are formed in the two ends of each gas outlet pipe D, and the gasoutlets of every two adjacent gas outlet pipes D are oppositely arranged.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Gas injection boiler using the emulsifying coke mortar combustion device

InactiveCN100529530CEfficient and stable combustionReasonable useCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCoke burnerProduct gas

The invention discloses a steam injection boiler adopting an emulsified coke slurry combustion device, which comprises a boiler body and an emulsified coke slurry combustion device. The smoke outlet on one end wall of the device. The emulsified coke slurry combustion device includes a shell surrounded by a front end wall, a rear end wall, and a side wall. A cylindrical combustion space is formed inside the shell. The front end wall is provided with At least one emulsified coke burner, and at least one oil burner and / or at least one gas burner, an outlet is opened on the rear end wall, and the outlet communicates with the furnace, wherein at least a part of the steam pipe in the furnace extends to the emulsified coke slurry In the side wall of the combustion device and adjacent to the inner surface of the side wall. In the present invention, the steam pipe is extended and arranged in the side wall of the combustion device, which effectively improves the dryness of the steam to 100%.

Owner:广州迪森热能设备有限公司

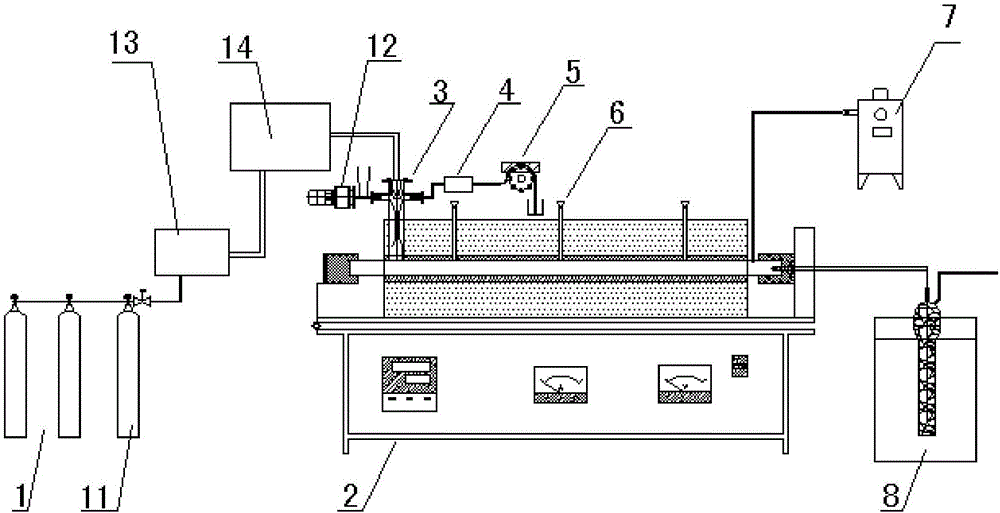

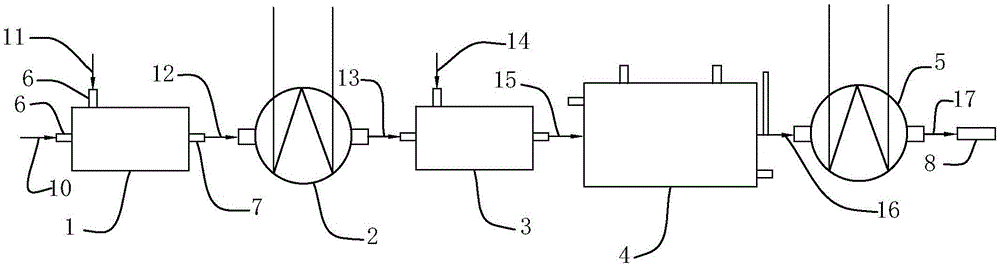

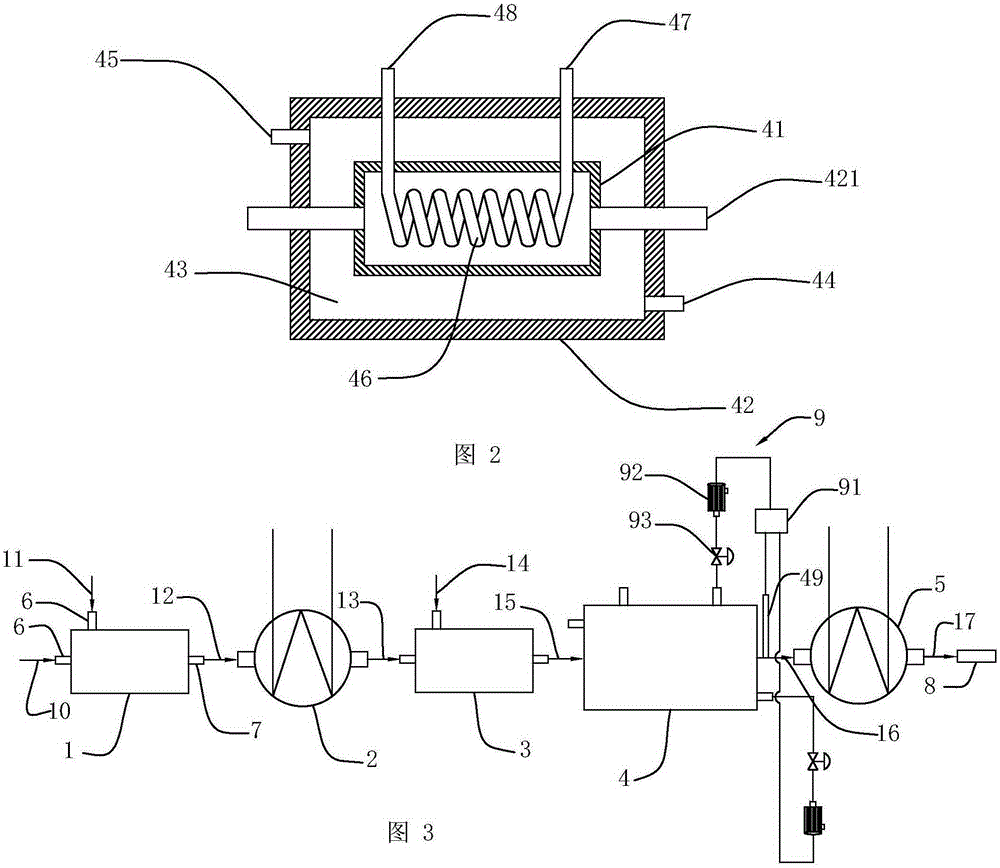

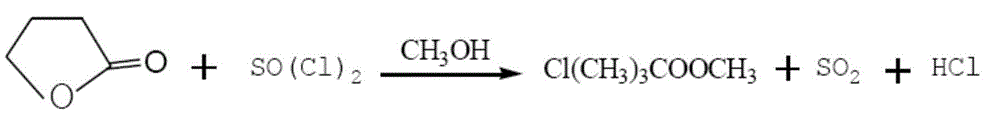

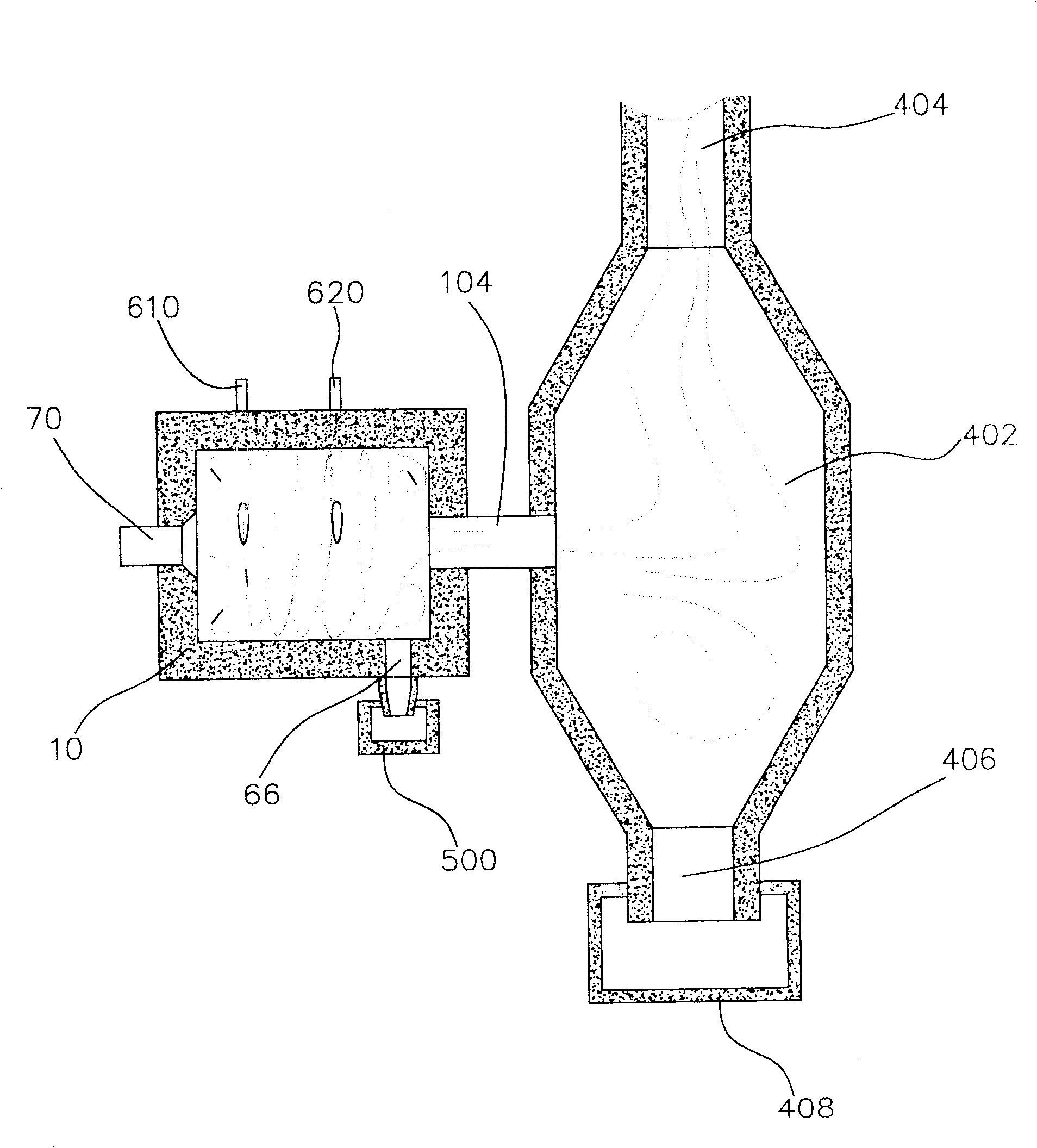

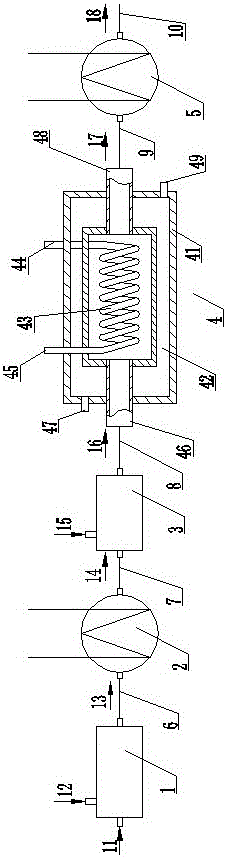

Preparation method and preparation device for gamma-chloro-methyl butyrate

InactiveCN105130815AMix vigorouslyAdequate responsePreparation by ester-hydroxy reactionTemperature controlAlcohol

The invention belongs to the technical field of drug intermediate synthesis, and particularly relates to a preparation method and preparation device for gamma-chloro-methyl butyrate. The preparation method comprises the following steps that gamma-butyrolactone and sulfoxide chloride are fed into a first-level jet mixer to be mixed and then sprayed into a preheater, and the temperature is increased to 30-35 DEG C; the mixture enters a second-level jet mixer, and meanwhile methyl alcohol is added in the second-level jet mixer; after mixing is performed, the mixture is sprayed into a static mixer, and the temperature is controlled at 52-55 DEG C; after a reaction is completed, the temperature is lowered, and then the gamma-chloro-methyl butyrate is obtained. The preparation device comprises the first-level jet mixer, the preheater, the second-level jet mixer, the static mixer and a cooler which are sequentially communicated; the first-level jet mixer and the second-level jet mixer are each provided with two liquid inlets and a liquid outlet, and the static mixer comprises a shell and a temperature control device arranged in the shell. According to the preparation method and preparation device for the gamma-chloro-methyl butyrate, continuous production can be achieved, the production efficiency is high, the product yield is high, and the cost is low.

Owner:SHANDONG GUOBANG PHARMA

Ceramic hot-blast furnace by emulsified coking slurry cyclone burner

InactiveCN100552291CImprove cleanlinessEfficient and stable combustionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneEngineering

This invention discloses a ceramic air heating furnace with the emulsification slurry wind burning device including vertical air heating furnace and the emulsification slurry wind burning device. The air heating furnace includes an egg-shape furnace chamber and the heat air opening. The emulsification burning device consists of a front end wall, back end wall and the side crust inside which forms a cylindraceous burning space. There are at least one emulsification burning device and at least a fuel burning device or at least air burning device. The back end wall has an outlet opening which connects to the egg-shape furnace chamber by the pipe. The side of the crust sets two or more tangential wind inlet openings and there are at least one dreg outlet opening near the back end wall at the side of the bottom of the burning space. The ceramic air heating furnace of this invention utilizes the emulsification burning device and the emulsification slurry as fuel so as to save the cost and maximize the utilization of the resource.

Owner:GUANGZHOU DEVOTION THERMAL TECH

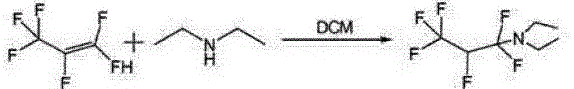

A method for continuously preparing ishikawa fluorinating agent and a reaction device for realizing the method

ActiveCN104478732BMix vigorouslyQuick responseAmino compound preparation by condensation/addition reactionsHexafluoropropyleneStatic mixer

The invention discloses a method and a reaction device for continuously preparing an Ishikawa fluorinating agent. The method comprises the following steps of mixing dichloromethane and diethylamine by virtue of a jet mixer to obtain a mixture, cooling the mixture by virtue of a cooler, mixing the cooled mixture and hexafluoropropylene by virtue of a jet mixer and fully reacting in a static mixer and rapidly cooling by virtue of a cooler. The entire process is rapidly completed in a few seconds and the problems of long reaction time and multiple side reactions are effectively solved. The reaction device comprises a primary jet mixer, a primary cooler, a secondary jet mixer, the static mixer and a secondary cooler which are sequentially arranged and has the advantages of simplicity in structure and convenience in use.

Owner:SHANDONG GUOBANG PHARMA

A vortex combustion device for metal and water reaction

InactiveCN104047759BExtended reaction timeImprove working abilityRam jet enginesCombustion chamberButt joint

The invention provides a swirl combustion device for metal and water reaction. The swirl combustion device for metal and water reaction comprises a combustion chamber, wherein the upper portion of the combustion chamber is an annular container, and the lower portion of the combustion chamber is a conical container. The annular container comprises an outer wall, an inner wall, an upper cover and a bottom cover, wherein the upper cover is used for connecting the inner wall and the outer wall, and the bottom cover is surrounded by the inner wall. A metal spray nozzle is arranged on the outer wall of the annular container, a water spray nozzle is arranged on the inner wall of the annular container, the position of the water spray nozzle corresponds to that of the metal spray nozzle, the upper portion of the conical container is in butt joint with the lower end of the outer wall of the annular container, and the bottom of the conical container is connected with a spray pipe. The swirl combustion device for metal and water reaction is simple in structure and reliable and can overcome the defect that because a compact oxidation film is formed on the surface of metal, combustion is affected; the diameter of molten metal liquid drops can be continuously reduced through shear force of swirls, the surface of unreacted metal is exposed so that the metal can react with water, and thus the metal and water reaction can go on stably, and the combustion efficiency of metal is improved.

Owner:HARBIN ENG UNIV

Industrial boiler using emulsifying coke mortar burning device

InactiveCN100594335CEfficient and stable combustionContinuous effective liquid slag removalCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSlurryEngineering

The present invention discloses an industrial boiler adopting emulsified coke slurry combustion equipment. It includes boiler self-body and emulsified coke slurry combustion equipment. The boiler self-body includes furnace cavity, boiler barrel set over the furnace cavity, water pipe which is set in the upper portion of said furnace cavity and is adjacent to the side wall of furnace cavity and fire pipe which is set in the central zone of boiler barrel and is soaked in the water of boiler barrel interior. Said emulsified coke slurry combustion equipment includes a shell body formed from frontend wall, rear end wall and side wall, in said shell body interior a cylindrical combustion space is formed, on the front end wall are set at least one emulsified coke slurry combustor, at least one oil combustor and / or at least one gas combustor and on the rear end wall an outlet is cut, said outlet is communicated with the furnace cavity. Said invention also provides the working principle of said industrial boiler and its concrete operation method.

Owner:广州迪森热能设备有限公司

Metallurgical reflecting kiln using the emulsifying coke mertar vortex burning device

InactiveCN101021314ALow costEfficient and stable combustionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelGas burnerProduct gas

The present invention discloses a metallurgic reflection kiln adopting emulsified coke slurry cyclone combustion equipment. It includes reflection kiln self-body and emulsified coke slurry cyclone combustion equipment. Its reflection kiln self-body includes kiln chamber, flame inlet and flue gas outlet. The emulsified coke slurry cyclone combustion equipment includes a shell body formed from front end wall, rear end wall and side wall, in the shell body interior a cylindrical combustion space is formed, on the front end wall are set at least one emulsified coke slurry combustor, at least one oil combustor and / or at least one gas combustor, on the rear end wall an outlet is cut, said outlet is communicated with flame inlet of kiln chamber by means of hot-air pipe, on the side wall of shell body two groups or more than two groups of tangential air inlets are space-set, on the side wall positioned in bottom portion of combustion space and in the position closed to rear end wall at least one liquid slag outlet is cut.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Metallurgical reflecting kiln using the emulsifying coke mertar vortex burning device

InactiveCN100535514CEfficient and stable combustionQuality assuranceCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneLiquid slag

The invention discloses a metallurgical reverberatory kiln adopting an emulsified coke slurry cyclone burning device, which comprises a reverberatory kiln body and an emulsified coke slurry cyclone burning device. It includes a shell surrounded by a front end wall, a rear end wall, and a side wall. A cylindrical combustion space is formed inside the shell, and at least one emulsified coke burner and at least one oil burner are arranged on the front end wall And / or at least one gas burner, an outlet is opened on the rear end wall, the outlet communicates with the flame inlet of the kiln chamber through the hot air pipe, and two or more sets of tangential air inlets are arranged at intervals on the side wall of the shell, located at At least one liquid slag outlet is opened on the side wall at the bottom of the combustion space at a position adjacent to the rear end wall. The metallurgical reverberatory kiln of the present invention adopts the emulsified coke slurry cyclone combustion device and uses the emulsified coke slurry as fuel, which saves fuel cost and realizes optimal utilization of resources.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Emusified coking-slurry cyclone burner

InactiveCN100501232CAvoid fouling and cokingReduce generationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneFlue gas

This invention discloses an emulsification burning device that consists of a front end wall, back end wall and the side crust inside which forms a cylindraceous burning space. There are at least one emulsification burning device and at least a fuel burning device or at least air burning device. The side of the crust sets two or more tangential wind inlet openings each of which includes two or more tangential wind inlet openings which can make the tangential wind inside the burning space form circumfluence along the side of the crust. There are at least one dreg outlet opening near the back end wall at the side of the bottom of the burning space. The cross section of the dreg outlet opening lies between the cross section of the tangential wind inlet opening near the back end wall and the inside of the back end wall. The emulsification burning device of this invention can realize the liquid slag avoiding the deposition and coking of the flue gases on the heating surface.

Owner:GUANGZHOU DEVOTION THERMAL TECH

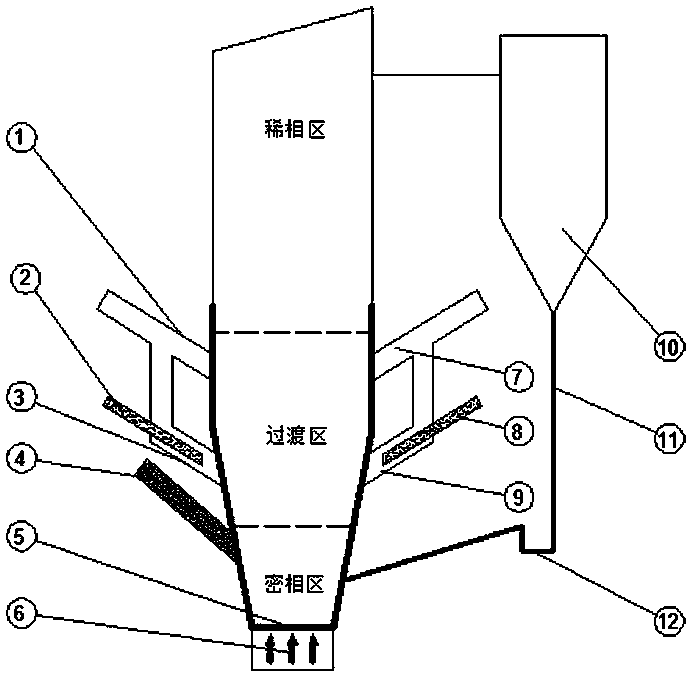

Pulverized coal medium-temperature circulating bed boiler

InactiveCN109539246AAvoid accumulationSolve the technical problem of conveying fine coal powderFluidized bed combustionApparatus for fluidised bed combustionCombustionFeeding tube

The invention provides a pulverized coal medium-temperature quick bed boiler. A coal feeding tube is arranged in a dense-phase area of the boiler, upper and lower secondary air tubes are divided intotwo layers and are arranged on a front wall and a back wall of a transition area of the boiler in a hedging mode, the secondary air tubes and the coal feeding tube are inclined downwards at the angleof 40 to 60 degrees, a pulverized coal flow conveying pipeline is connected to the interiors of the secondary air tubes, the residual coal supply is directly connected to the coal feeding tube, secondary air enters from the secondary air tubes, coarse coal grains of 100 mum to 1000 mum are fed from a coal inlet of the circulating bed boiler, fine pulverized coal of 0 to 100 mum is sent to a hearthfrom a lower secondary air inlet, the pulverized coal can be sent to the middle of the hearth by virtue of the momentum of the secondary air, the pulverized coal is inclined downwards first and thenis driven upwards by primary air so as to form a W-shaped combustion mode, and the upper secondary air is used as over-fire air. According to the pulverized coal medium-temperature quick bed boiler, graded coal supply is adopted, so that the coal supply is effectively prevented from stacking on a bed; the pulverized coal is carried by the secondary air and can be conveyed to a central high-temperature area of the hearth to burn, so that the technical problem of conveying the fine pulverized coal to the circulating bed boiler is solved.

Owner:马素霞

Glass kiln with emulsified coke slurry burner

InactiveCN101020596BEfficient and stable combustionMake up for the shortcomings of low calorific valueGlass furnace apparatusGlass productionBurn unitsBrick

The glass kiln with emulsified coke slurry burner includes one kiln body and one emulsified coke slurry burner. The kiln body includes one hearth, one flame inlet and one fume outlet. The emulsified coke slurry burner includes one casing forming one inside cylindrical burning space, at least one emulsified coke slurry burning unit, at least one oil / gas burner, one outlet communicated via hot blast pipe to the flame inlet of the hearth. The glass kiln includes also two or more switchable heat accumulating chambers connected via pipeline with the fume outlet of the kiln body. The present invention has double heat accumulation with lattice brick and ceramic ball reaching a heat accumulating temperature as high as 1200 deg.c to make up the low heat value emulsified coke slurry.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Emusified coking-slurry lean-oxygen burner

InactiveCN100501233CReduce generationEnhanced mixed combustion intensityCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelEngineeringSlurry

This invention discloses a low-oxygen burning device of emulsification serum coke including front-end wall, back-end wall and side-wall shell in which there is the cylindraceous burning space. On the top of the front-end wall there are at least an emulsification serum coke burning device and an oil burning device or at least a gas burning device. The emulsification serum coke burning device sets a one-time air distribution intake which is used to carry the warm-up air to the burning space. The side wall of the shell is set interval with two or more tangential intakes which is used to carry the non-warm air that amounts to 0.06-0.1 times of the total warm-up air to the burning space. Each tangential intake includes even setting three or more tangential intakes. The vertical distance between the inside wall of the back-end wall and the inside wall of the front-end wall is 2 or 4 times of the diameter of the burning space. The invention emulsification serum coke burning device can burn with high efficiency under lower air coefficient.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Heat conductive oil furnace using emulsifying coke mortar vortex burning device

InactiveCN101021357BEfficient and stable combustionContinuous effective liquid slag removalCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelLiquid slagHeat conducting

The invention discloses a heat-conducting oil stove used the emulsifying burnt plasma vortex burning device. It includes the oil stove body and the emulsifying burnt plasma vortex burner which includes the shell composed by the front wall, the back wall and the side wall. The burning room is formed in the shell. At least one emulsifying burnt plasma vortex burner and at least one oil burner or atleast one gas burner is set in the front wall; an outlet is set in the back wall which is connected with the flame inlet of furnace chamber by the warm-air pipe. The two or above groups of tangentialwind inlets are set on the shell side wall alternately; the outlet of the liquid slag is on the side wall of the burning room bottom which is near to the back wall. The invention uses the emulsifyingburnt plasma as the fuel, so it can save the cost.

Owner:广州迪森热能设备有限公司

Liquid-type slag releasing device of emulsifying coke mortor

InactiveCN100538180CEfficient and stable combustionAvoid fouling and cokingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelEmulsionLiquid slag

The invention discloses a liquid slag discharge device for emulsified coke slurry, which comprises a shell surrounded by a front end wall, a rear end wall, and a side wall. A cylindrical combustion space is formed inside the shell, and the front end wall is provided with At least one emulsified coke slurry burner, and at least one oil burner and / or at least one gas burner, at least one liquid slag outlet is provided on the side wall at the bottom of the combustion space near the rear end wall, and the emulsified coke slurry is discharged in liquid state. The slag device further includes two or more slag discharge vehicles that work alternately, one of the two or more slag discharge vehicles stays below the liquid slag outlet, and the slag discharge vehicle that stays below the liquid slag outlet The slag holding space communicates with the liquid slag outlet, and the connection between the slag holding space and the liquid slag outlet is sealed. The invention adopts two or more specially designed slag discharge vehicles to work alternately, which not only ensures efficient and stable combustion of emulsified coke slurry, but also realizes continuous and effective liquid slag removal.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com