A vortex combustion device for metal and water reaction

A combustion device and water reaction technology, applied in ramjet engines, mechanical equipment, etc., can solve the problems of insufficient chemical performance, low mixing efficiency of metal and water reaction, etc., to increase energy utilization rate, enhance combustion characteristics, The effect of improving working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

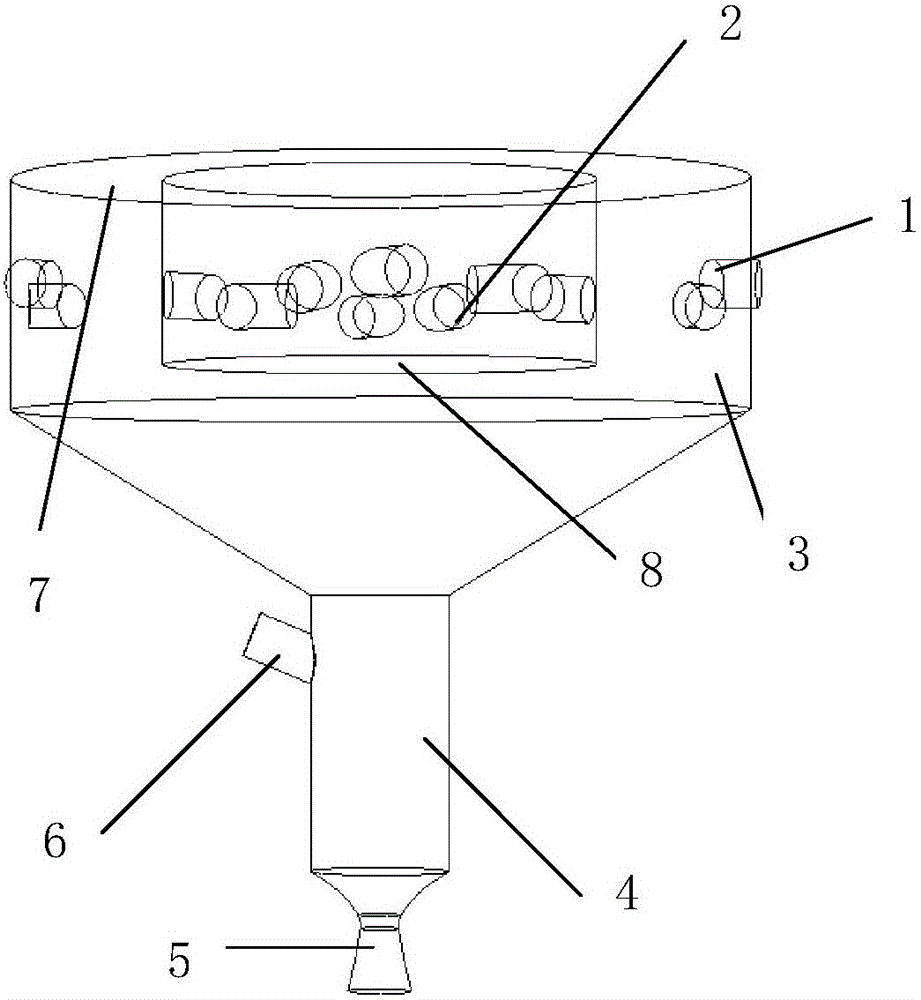

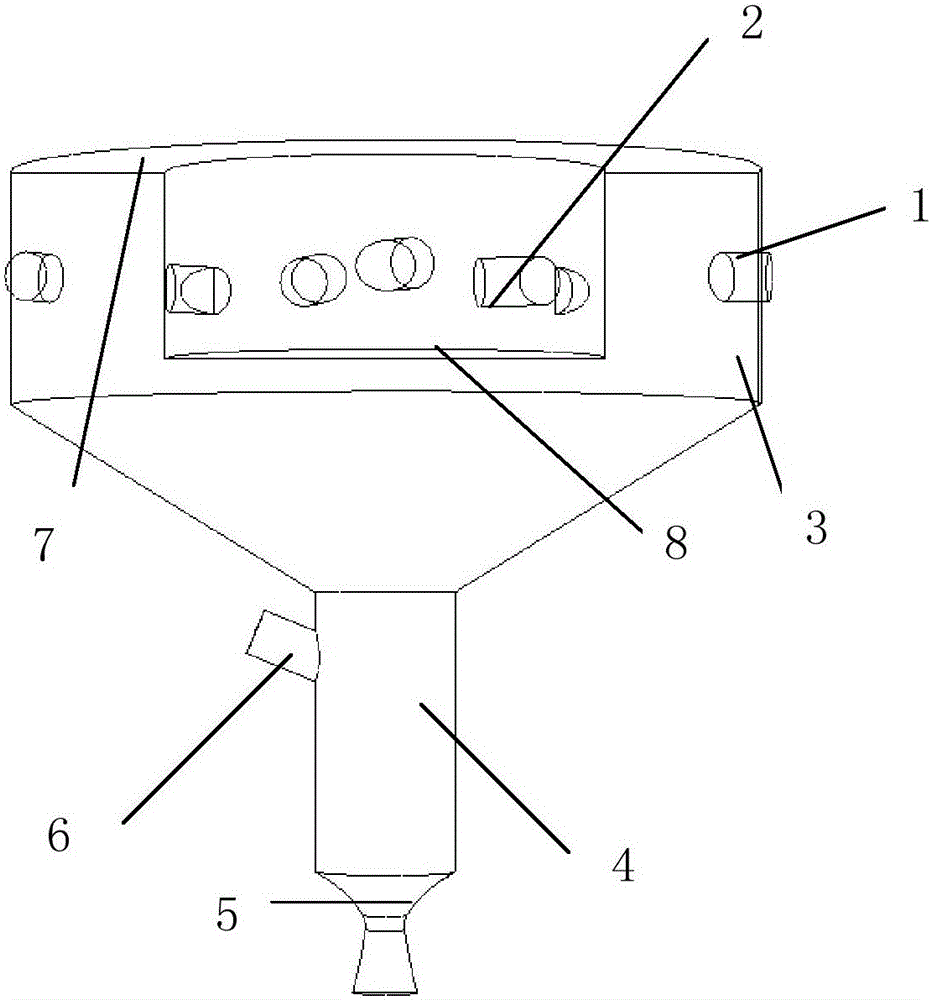

[0014] Implementation Case 1: Combination figure 1 The vortex combustion device of the present invention includes a combustion chamber 3. The upper part of the combustion chamber 3 is a circular container and the lower part is a conical container. The circular container includes an outer wall, an inner wall, and an upper cover 7 connecting the inner wall and the outer wall. The bottom cover 8 surrounded by the inner wall, the outer wall of the annular container is provided with a metal nozzle 1, and the inner wall of the annular container is provided with a water nozzle 2. The position of the water nozzle 2 corresponds to the position of the metal nozzle 1. The upper part of the conical container is connected to the ring The lower end of the outer wall of the conical container is butted, and the bottom of the conical container is connected with the nozzle 5, which has a gradually expanding shape. The upper end of the upper part of the circular container runs through, that is, an...

Embodiment example 2

[0016] Implementation case 2: According to the vortex combustion device described in implementation case 1, a secondary combustion chamber 4 is provided at the bottom of the conical container, and the outer wall of the secondary combustion chamber 4 is provided with a secondary water injection nozzle 6, and the nozzle 5 is connected to the secondary combustion chamber 6 The outlet location is connected.

[0017] Then the neutral gas and water vapor after the reaction in the combustion chamber will drive the incompletely reacted metal particles to move to the nozzle outlet direction, first enter the secondary combustion chamber 4, and set an upper part of the secondary combustion chamber 4 With the secondary water injection nozzle 6, the unreacted and incompletely reacted metal particles and the water injected by the secondary water injection nozzle 6 are subjected to secondary combustion, which increases the energy utilization rate, and also improves the functional power of the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com