Environment-friendly clay stabilizer for oil well fracturing as well as preparation device and preparation method

A technology of clay stabilizer and preparation device, which is applied in the direction of chemical instruments and methods, drilling compositions, chemical/physical/physicochemical fixed reactors, etc., which can solve the problems of long stirring time and insufficient mixing, and achieve It is beneficial to oil production, fracturing effect improvement, and the effect of inhibiting formation clay expansion and clay particle migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 An environmentally friendly clay stabilizer for oil well fracturing

[0037] This example discloses an environment-friendly clay stabilizer for oil well fracturing, which comprises the following components in parts by weight: 20 parts of calcium chloride dihydrate, 8 parts of fatty alcohol, and 6 parts of alkyl polyoxyethylene ether , 12 parts of sodium dodecylbenzenesulfonate, 20 parts of methanol.

[0038] The clay stabilizer of this embodiment can effectively inhibit formation clay swelling and clay particle migration, which is beneficial to the oil production of oil wells; it is used for anti-swelling in acid fracturing and water injection projects, and it does not need drainage aids when configuring fracturing fluids It reduces the cost and facilitates the preparation of fracturing fluid, and the fracturing effect is significantly improved.

Embodiment 2

[0039] Example 2 A preparation device for an environmentally friendly clay stabilizer for oil well fracturing

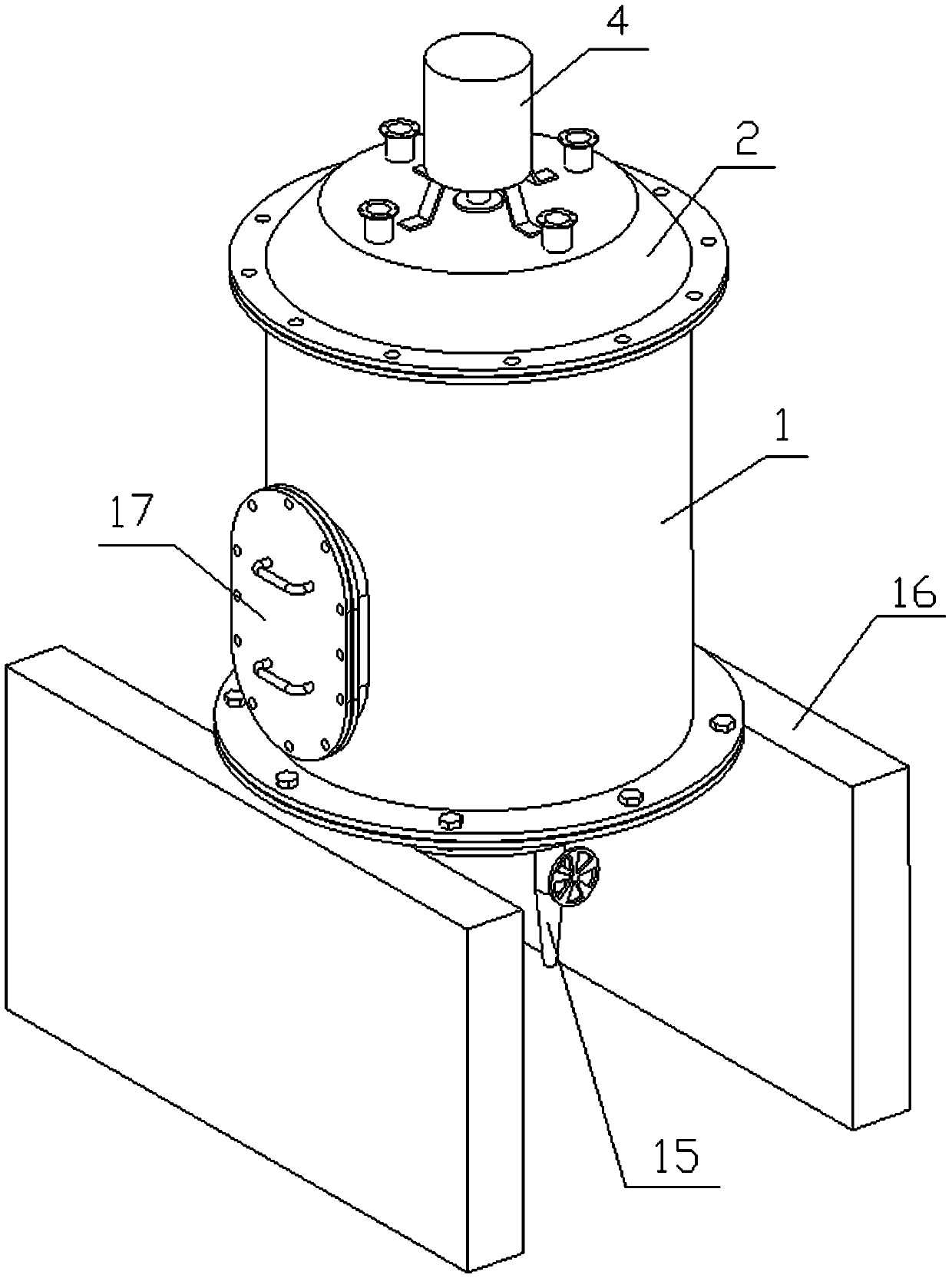

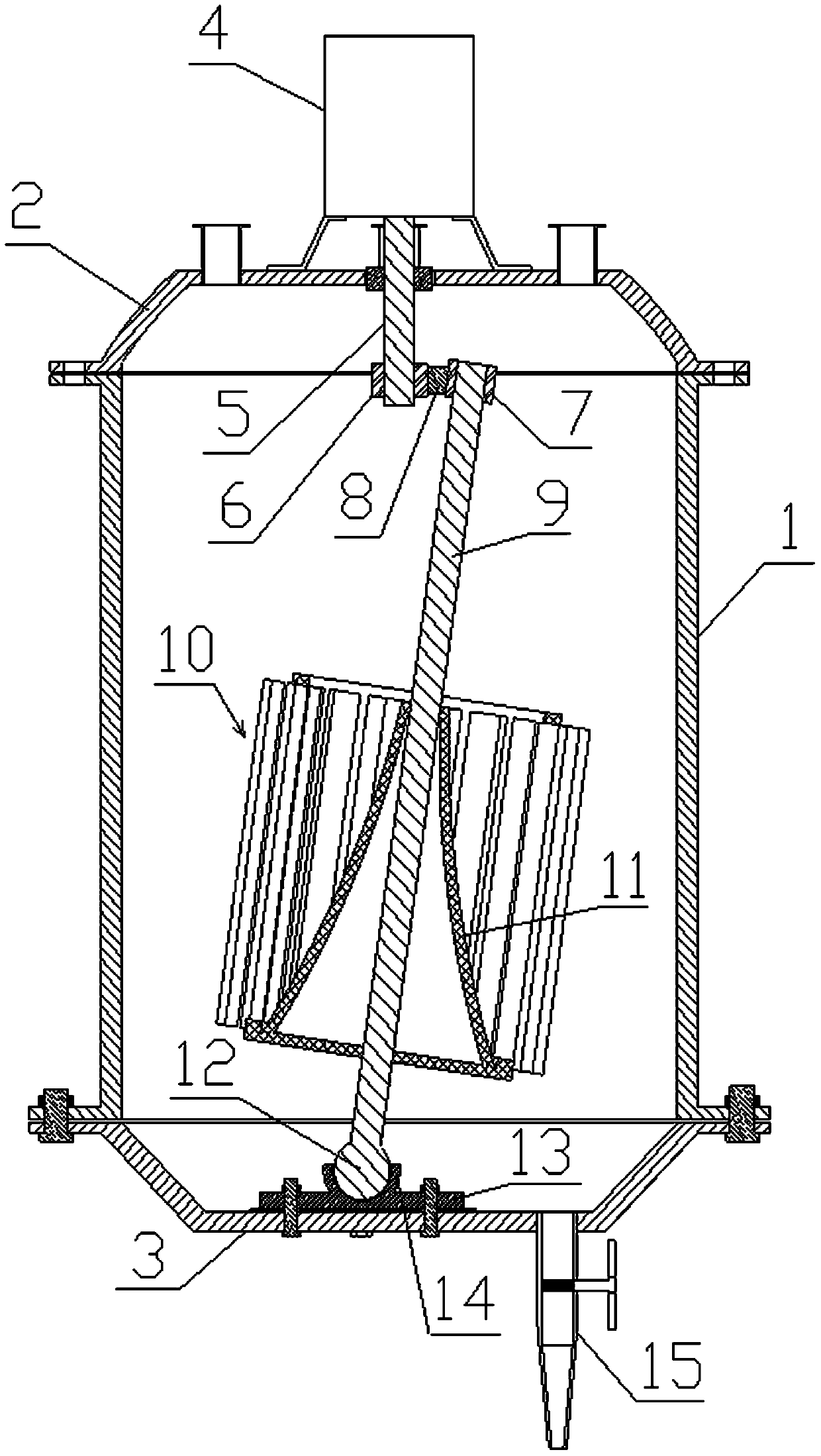

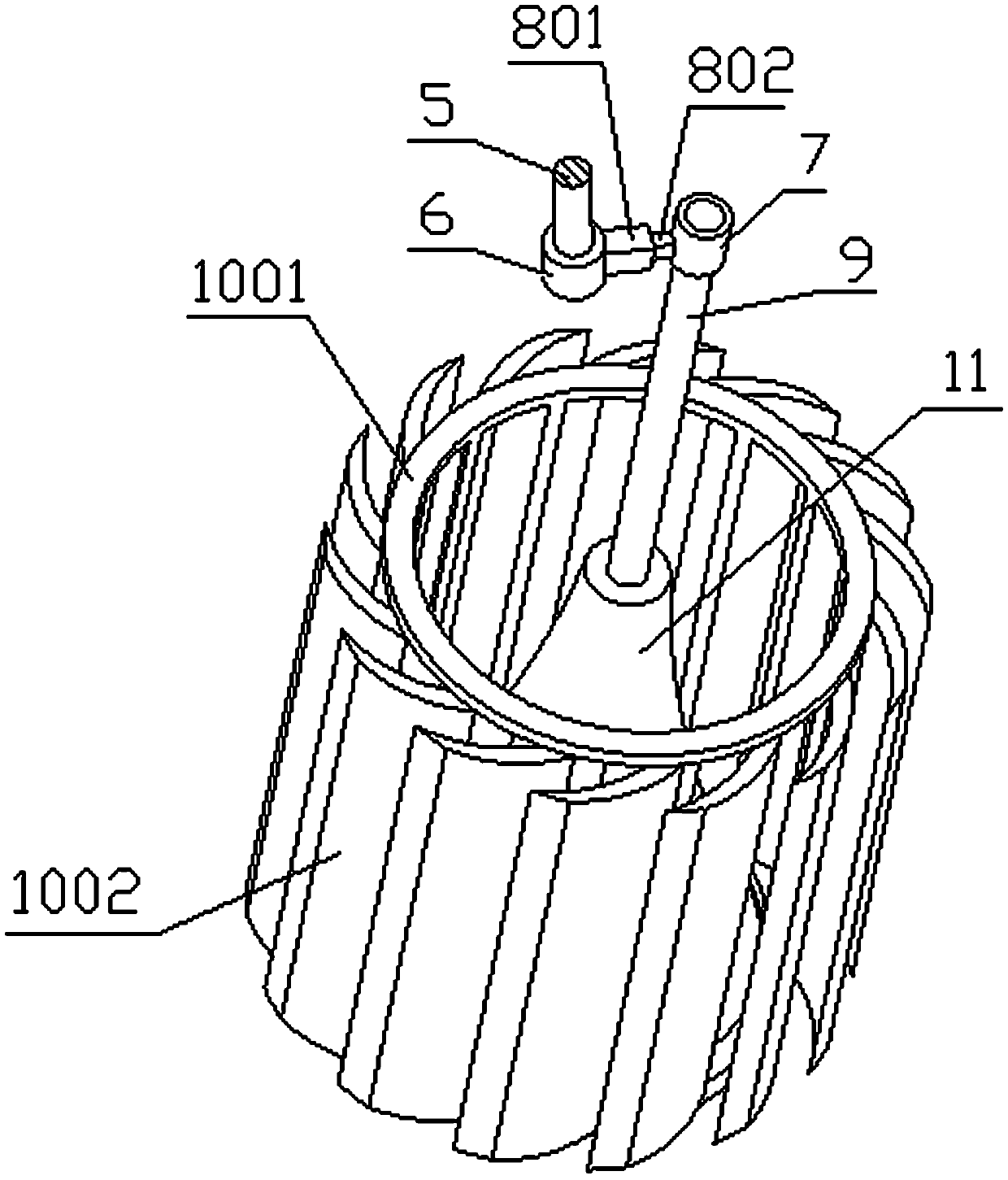

[0040] This embodiment discloses a preparation device for an environmentally friendly clay stabilizer for oil well fracturing, such as figure 1 , figure 2Shown, including the reactor and stirring mechanism. Wherein, the reaction kettle includes a kettle body 1, the upper and lower ends of the kettle body 1 are detachably connected with an upper cover 2 and a lower cover 3 respectively, and a side cover 17 is detachably connected with the kettle body 1, and the side cover 17 is used for the kettle body 1 It is opened during internal inspection and regular maintenance, and a discharge pipe 15 is connected to the lower cover 3 . The stirring mechanism includes a driving motor 4, a stirring shaft 9 and a mixing drum 10, the driving motor 4 is installed on the upper cover 2, the output shaft 5 of the driving motor 4 extends vertically into the reactor, and the output s...

Embodiment 3

[0046] Example 3 A preparation method of an environmentally friendly clay stabilizer for oil well fracturing

[0047] This embodiment discloses a preparation method of an environmentally friendly clay stabilizer for oil well fracturing, and its specific steps are as follows:

[0048] S1. Add water to the reactor, turn on the driving motor to stir the reactor, and then add calcium chloride dihydrate;

[0049] After S2, 40min, add fatty alcohol;

[0050] After S3, 40min, add alkyl polyoxyethylene ether;

[0051] S4, increase the rotating speed of driving motor, add sodium dodecylbenzene sulfonate after 40min;

[0052] After S5, 40min, add methanol;

[0053] S6. Control the drive motor to rotate with frequency conversion. After 90 minutes, turn off the drive motor, let stand for 60 minutes, and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com