Preparation method and preparation device for gamma-chloro-methyl butyrate

A technology for preparing methyl chlorobutyrate and a preparation device, which is applied in the field of preparation method and preparation device of methyl γ-chlorobutyrate, can solve problems such as fluctuations in product quality, high labor intensity, and large environmental pollution, and achieve Reduce production costs, reduce labor intensity, and stabilize the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

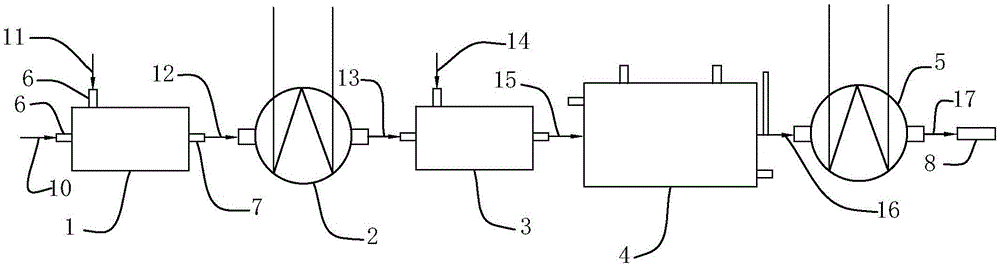

[0031] figure 1 A schematic structural view of the preparation device of methyl γ-chlorobutyrate provided in this example is shown. For the convenience of description, this figure only provides the structural parts related to the present invention.

[0032] A preparation device for methyl gamma-chlorobutyrate, such as figure 1 As shown, it includes a primary jet mixer 1 , a preheater 2 , a secondary jet mixer 3 , a static mixer 4 and a cooler 5 connected in sequence. The first-stage jet mixer 1 and the second-stage jet mixer 3 have the same structure, and are all existing products. For example, the products of models such as SX / SK / SV / SL can be produced by Qidong mixer factory, and its structure will not be repeated here. The first-stage jet mixer 1 and the second-stage jet mixer 3 are respectively provided with two liquid inlets 6 and one liquid outlet 7, and the preheater 2 and the cooler 5 have the same structure, for example, a tube-and-tube heat exchanger can be used , p...

Embodiment 2

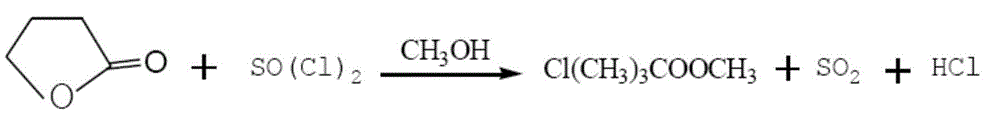

[0035] image 3 A schematic structural view of the preparation device of methyl γ-chlorobutyrate provided in this example is shown. For the convenience of description, this figure only provides the structural parts related to the present invention.

[0036] The preparation device of gamma-chlorobutyric acid methyl ester in the present embodiment is basically identical with the structure in embodiment one, difference is:

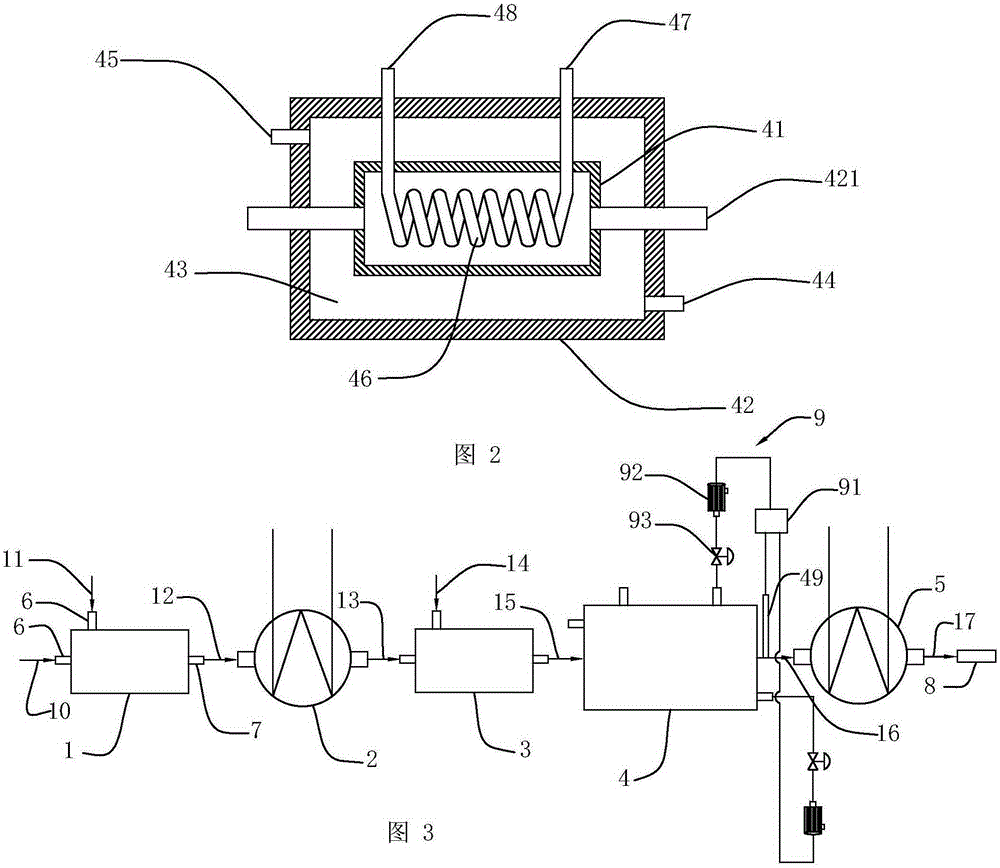

[0037] Such as image 3 As shown, the preparation device also includes an automatic flow control system 9, the automatic flow control system 9 is located outside the outer shell 42, the automatic flow control system 9 includes a controller 91, a motor 92 and a flow valve 93, the controller 91 and the motor 92 Electrically connected, the motor 92 is connected to the flow valve 93 in transmission, the cooling medium inlet 45 and the heat medium inlet 47 are respectively provided with flow valves 93 , and the temperature control probe 49 is electrically connect...

Embodiment 3

[0040] (1) Feed γ-butyrolactone 1mol into the first-stage jet mixer with a flow rate of 400g / h, and pass into thionyl chloride 1.3mol with a flow rate of 719g / h simultaneously, and the two materials are in the first-stage jet mixer The mixed liquid is formed in the middle, and the mixed liquid is sprayed out from the first-stage jet mixer and directly enters the preheater, and is heated to 30°C to form a mixed liquid;

[0041] (2) The mixed solution directly enters the secondary jet mixer, and simultaneously delivers 2 mol of methanol to the secondary jet mixer at a flow rate of 297g / h, thereby forming a premixed solution of the mixed solution and methanol in the secondary jet mixer;

[0042] (3) The premixed liquid is sprayed out from the secondary jet mixer and directly enters the static mixer. The premixed liquid is strongly mixed and continuously reacted in the static mixer. The reaction temperature is controlled by the temperature control device of the static mixer, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com