Gas inlet device of chloromethane reaction tower

A technology of air inlet device and reaction tower, which is applied in the direction of feeding device, chemical instrument and method, chemical/physical process, etc., can solve the problems of small divergence area, increased welding amount, and inability to ensure that the gas can fully contact and react.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

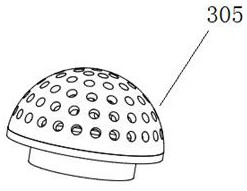

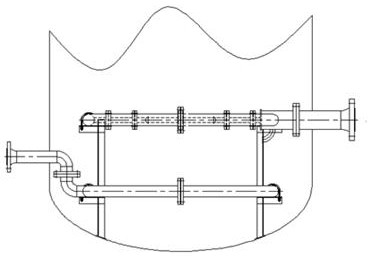

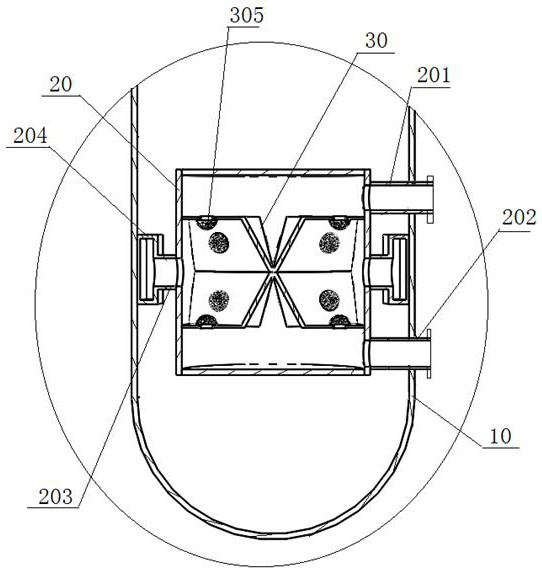

[0029] Such as Figure 1~5 As shown, a gas inlet device of a methyl chloride reaction tower includes a tower body 10, and also includes a sealed reaction barrel 20, which is fixedly connected in the tower body 10; an air inlet pipe A201, one end of which is fixedly communicated with the upper part of the reaction barrel 20 1. The other end stretches out of the tower body 10; the air intake pipe B202, one end is fixedly connected to the bottom of the reaction barrel 20, and the other end extends out of the tower body 10; a plurality of connecting pipes C203, one end is fixedly connected to the reaction barrel 20, and the other end is fixedly connected In the middle of the arc-shaped air outlet pipe D204, the connecting pipe C203 is located between the air inlet pipe A201 and the air inlet pipe B202, and is distributed along the circumference of the reaction barrel 20. Both ends of the air outlet pipe D204 are provided with air outlets, and two adjacent outlets The gas outlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com