Polyurethane retardant catalyst, and preparation method and application thereof

A delayed and polyurethane technology, which is applied in the field of delayed catalysts for polyurethane foaming, can solve problems such as unsatisfactory delayed effects and failure to meet requirements, and achieve excellent delayed catalytic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The triethylenediamine (moisture content 2%) that takes by weighing 114g (1.0mol) is dissolved in 300ml ethanol and joins in the 250ml there-necked flask, then places in ice-water bath, takes by weighing 155g (1.0mol) diethyl sulfate ( Moisture content 0.9%) after being dissolved in 300ml ethanol, join in the 500ml constant pressure funnel, fix the constant pressure funnel on the three-necked flask, add diethyl sulfate+ethanol mixture dropwise in the three-necked flask, wait for the solution to drip After the addition was complete, the temperature of the water bath was raised to 25°C for two hours of reaction. The whole process needs to be stirred with a magnet to ensure that the reactants are fully mixed. After completion of the reaction, ethanol was removed by rotary evaporation under reduced pressure at 70°C, and finally, vacuum-dried at 70°C for 48 hours to obtain triethylenediamine diethyl sulfate salt.

Embodiment 2

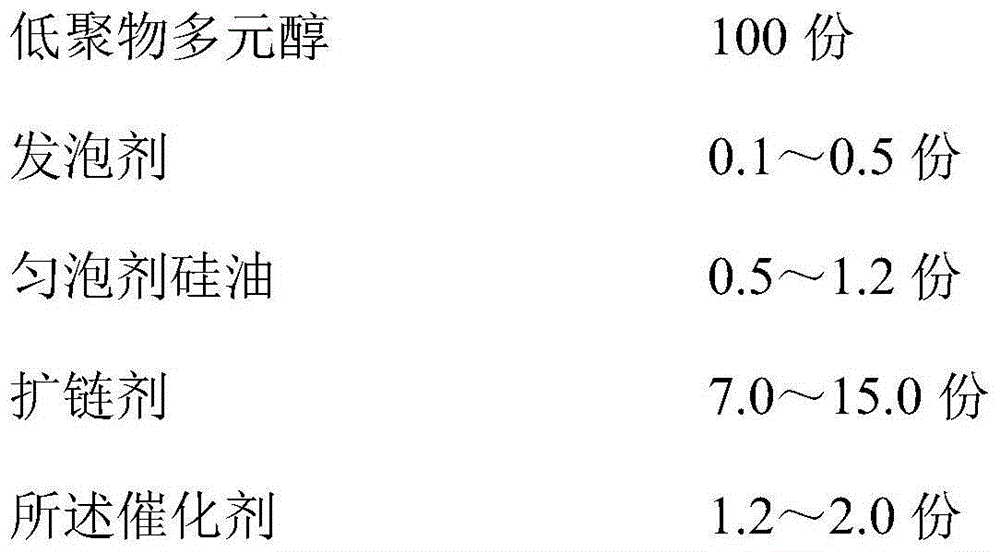

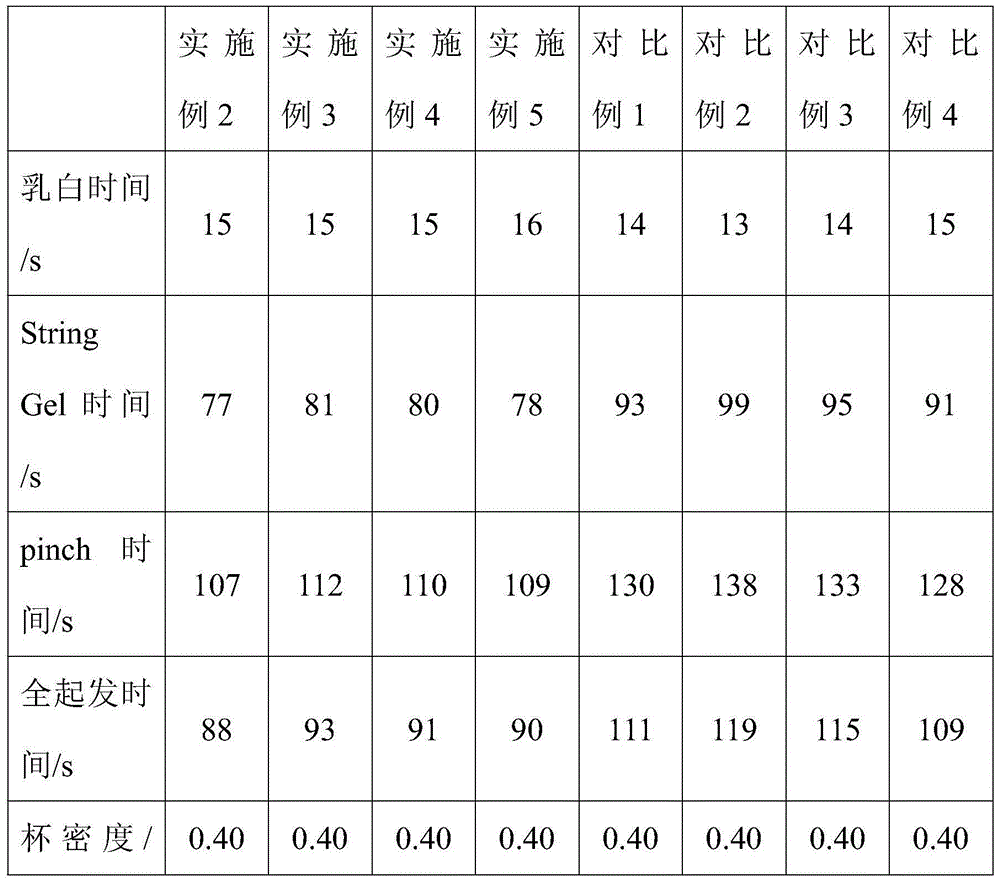

[0031] (1) 6.00kg molecular weight is 1500 polyhexamethylene adipate, 4.00kg molecular weight is 1500 polytetrahydrofuran diol, 0.12kg triethylenediamine diethyl sulfate salt, 0.01kg distilled water, 0.05kg organosilicon Foaming agent, 0.70kg 1,4-butanediol mixed evenly, as component A of polyurethane resin; (2) 1.16kg polyhexamethylene adipate, 3.87kg 4,4'-xylene methane diisocyanate (MDI ) mixed reaction, control the reaction temperature to 60°C, and after 4 hours of reaction time, use it as component B of polyurethane resin.

Embodiment 3

[0033] (1) 5.00kg molecular weight is 2000 polyhexamethylene adipate, 5.00kg molecular weight is 2000 polytetrahydrofuran diol, 0.15kg triethylenediamine diethyl sulfate salt, 0.03kg distilled water, 0.08kg organic silicon Foam stabilizer, 0.40kg ethylene glycol and 0.60kg 1,4-butanediol are mixed uniformly as component A of polyurethane resin; (2) 2.47kg polyhexamethylene adipate, 4.95kg 4,4'-xylene Mix reaction of methane diisocyanate (MDI), control the reaction temperature to 80°C, and react for 3 hours, then use it as component B of polyurethane resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com