Method and device for repairing downhole coal-bed gas extraction drilled hole

A technology for drilling and coal seam gas drainage, applied in the direction of gas discharge, safety devices, mining equipment, etc., can solve problems such as difficulty in inserting drainage pipes, failure to discharge large-sized coal slag and rock slag, etc., and achieves easy operation and applicable scope Wide and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

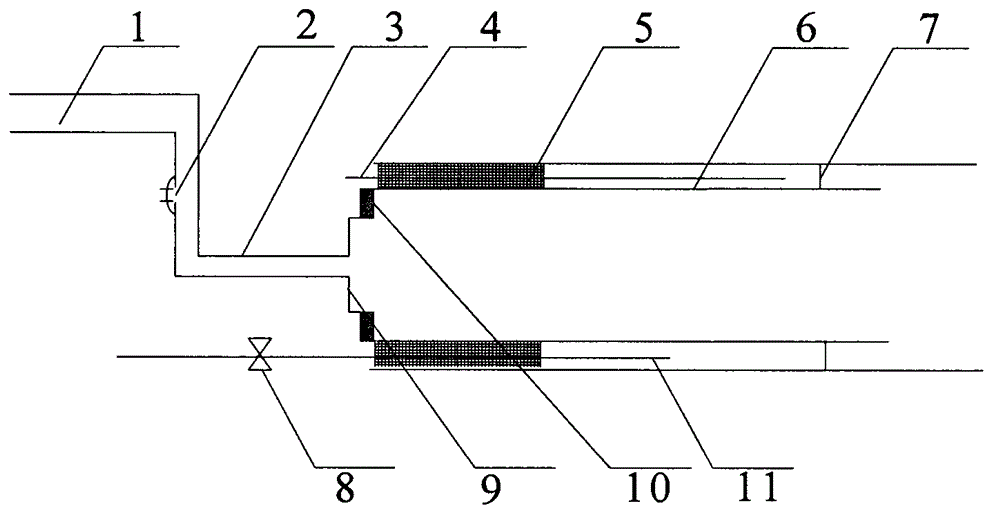

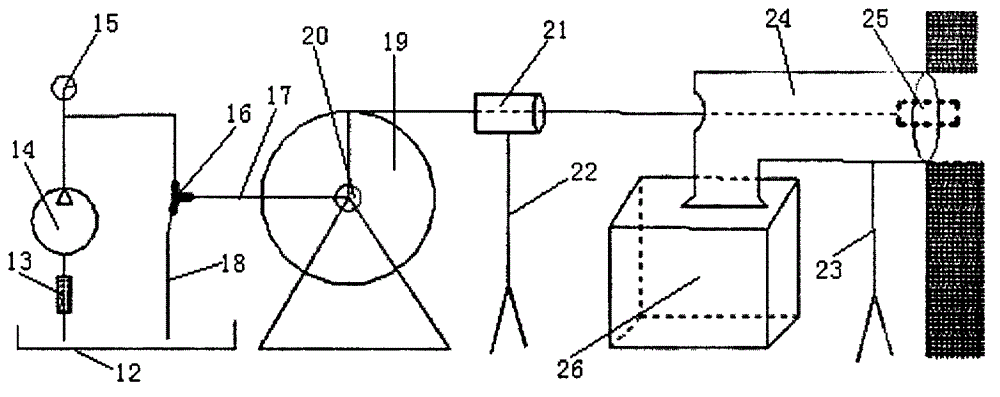

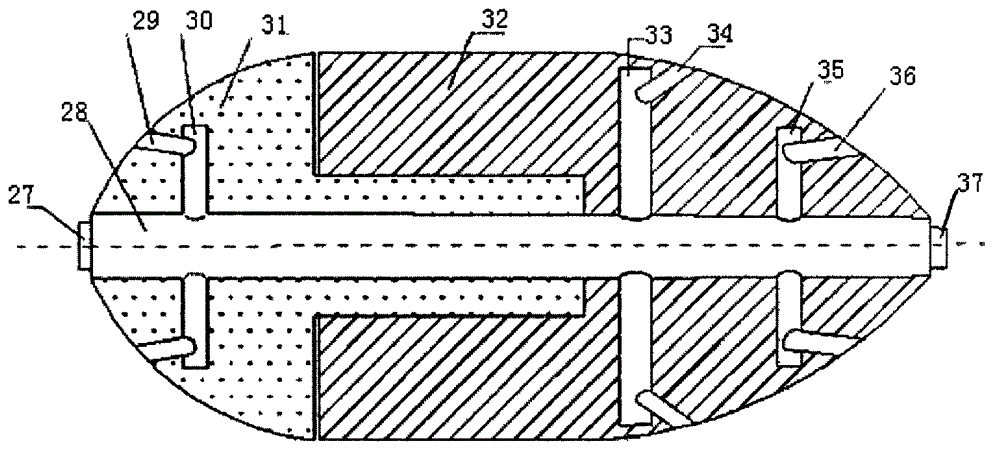

[0025] Such as Figure 1-2 As shown, the present invention provides an underground coal seam gas drainage borehole repair method, which is suitable for occasions where the gas extraction rate is reduced due to borehole collapse and failure, that is, a hydraulic self-driving system device is used to discharge slag and restore Borehole drainage capacity. The hydraulic self-driving drill bit used in this method is not limited by the drilling conditions. Driven by high water pressure, it can reach the bottom of the borehole to complete slag discharge and dredging.

[0026] The specific technical scheme of the present invention is: an underground coal seam gas drainage bore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com