Planet carrier casting material used for self-elevating offshore platform lifting gear box and production method

An offshore platform, self-elevating technology, applied in the direction of belt/chain/gear, hoisting device, transmission device parts, etc., can solve the problems of easy damage, complex manufacturing process and high production cost, to eliminate excessive stress concentration, Improve the anti-destructive ability and the effect of smooth feeding channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

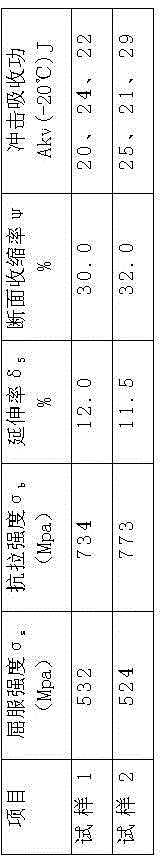

[0099] Example 1: A steel casting material of planet carrier for lifting gearbox of jack-up offshore platform with high speed ratio and super high torque. The mass percentage control range of chemical composition is as follows: C: 0.28~0.35%, Si: 0.20~0.35% , Mn: 0.65~0.85%, S: ≤0.030%, P: ≤0.030%, Cr: 0.85~0.95%, Mo: 0.20~0.26%, V: 0.04~0.08%, Ti: 0.02~0.06%, the rest content For Fe.

Embodiment 1-1

[0100] Example 1-1: On the basis of Example 1, C: 0.28%, Si: 0.20%, Mn: 0.65%, S: ≤0.030%, P: ≤0.030%, Cr: 0.85~0.95%, Mo: 0.20~0.26%, V: 0.04%, Ti: 0.02%, the remaining content is Fe.

Embodiment 1-2

[0101] Example 1-2: On the basis of Example 1, C: 0.35%, Si: 0.35%, Mn: 0.85%, S: ≤0.030%, P: ≤0.030%, Cr: 0.95%, Mo: 0.26% , V: 0.08%, Ti: 0.06%, the remaining content is Fe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com