Underpressure before the valve automatically shuts down the pressure regulator

An automatic shut-off and pressure regulator technology, which is applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of high labor intensity in operating valves, time-consuming operation and management costs, backward operation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

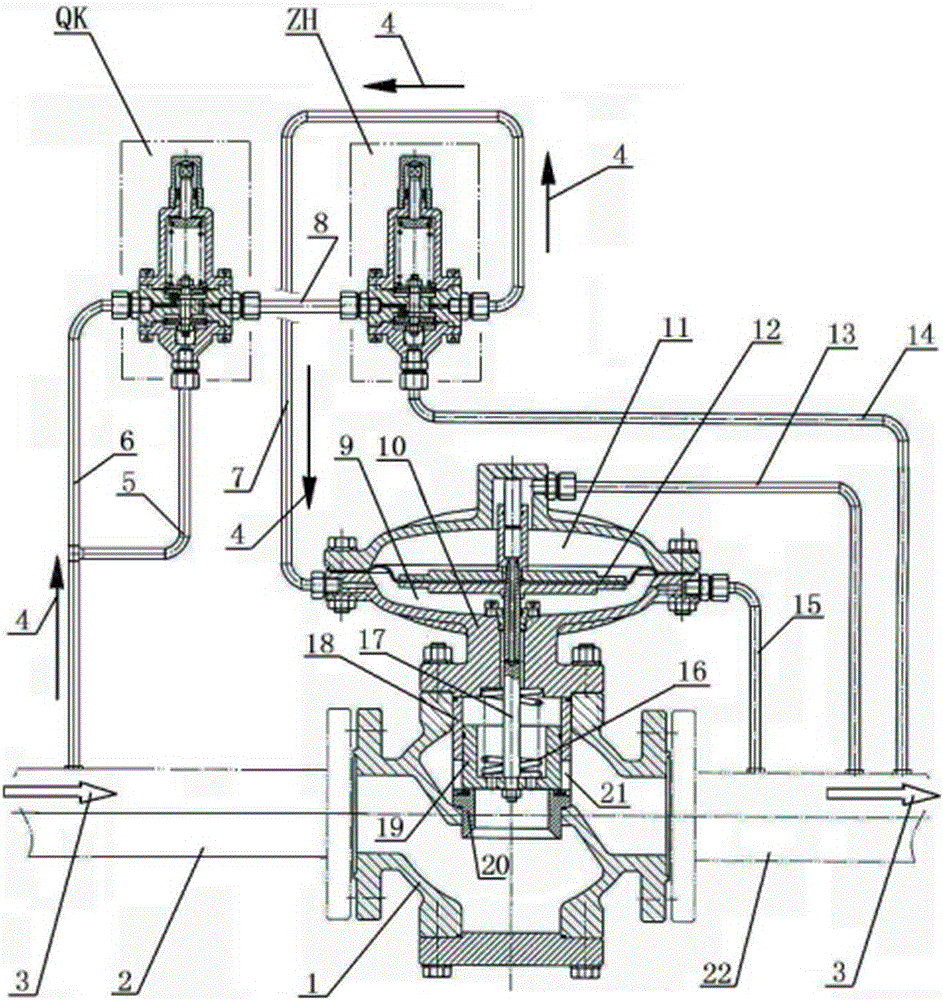

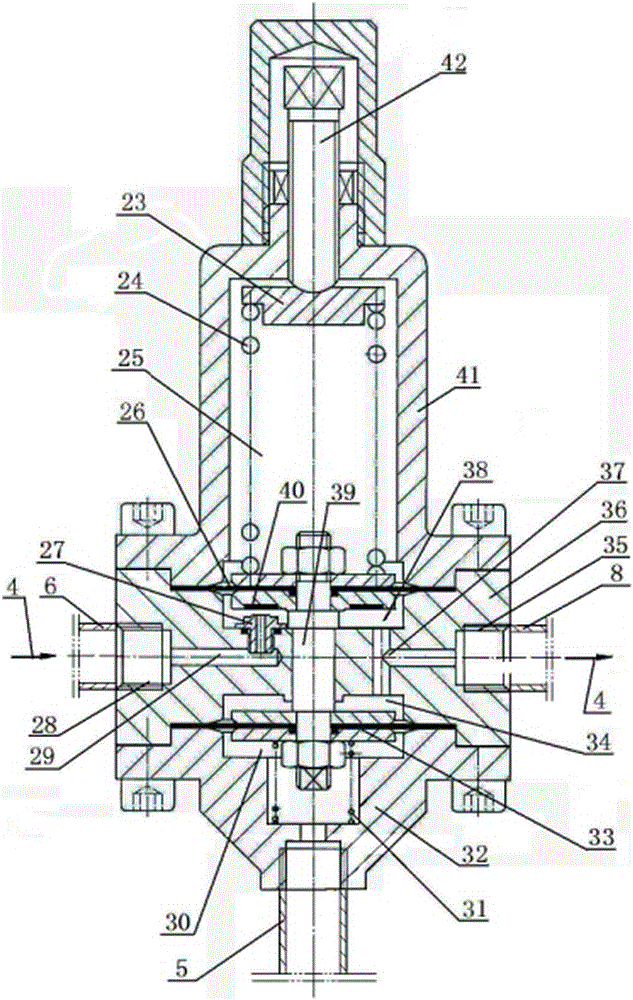

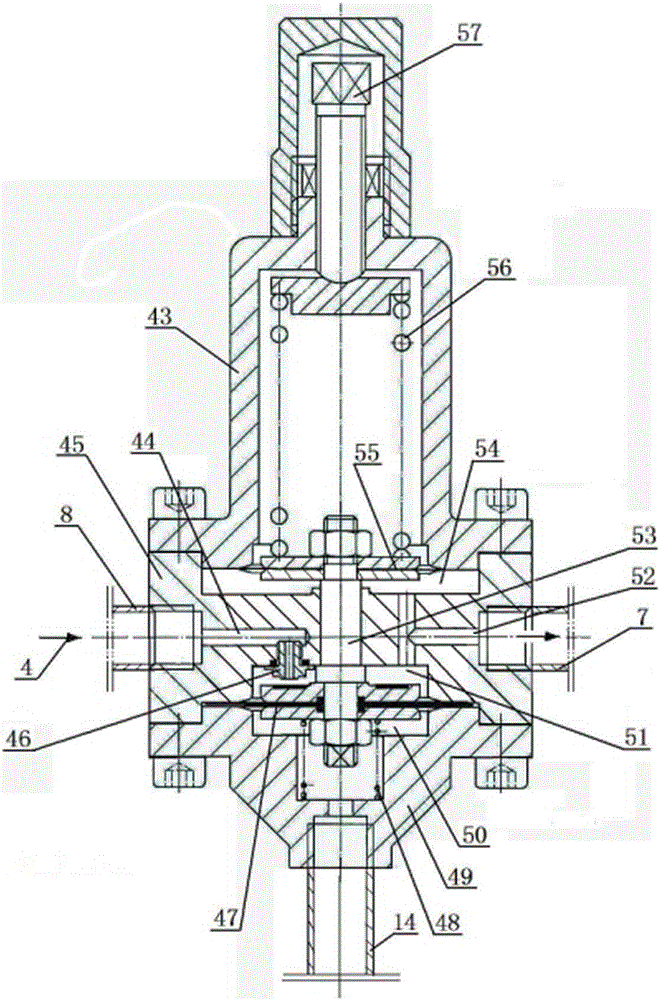

[0014]A pre-valve under-pressure automatic closing pressure regulator, which is mainly composed of a main valve 1, a pilot ZH, an under-voltage closing controller QK, a front pressure pipe 5, a front pressure input pipe 6, a pressure regulating inlet pipe 8, and a pressure regulating outlet The air pipe 7, the pressure pipe 13 after the main adjustment, the pressure pipe 14 after the throttle, and the return pipe 15 are composed. The main valve 1 is equipped with a valve seat 20, a cage valve sleeve 18, a valve core 19, a valve stem 17 and a main adjustment valve. Spring 16, the main valve 1 is fixedly installed with the main adjustment diaphragm box 10, and the main adjustment diaphragm box 10 is equipped with a diaphragm assembly 12, which is divided into an upper air chamber 11 and a lower air chamber 9, and the upper end of the valve stem 17 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com