High-efficiency tritium removal purification device and tritium removal method thereof

A tritium purification and high-efficiency technology, which is applied in the field of radioactive waste recovery and purification devices, can solve the problems of no de-tritium purification device, etc., and achieve the effect of rapid de-tritium purification treatment, ensuring catalytic oxidation efficiency, and protecting the safety of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

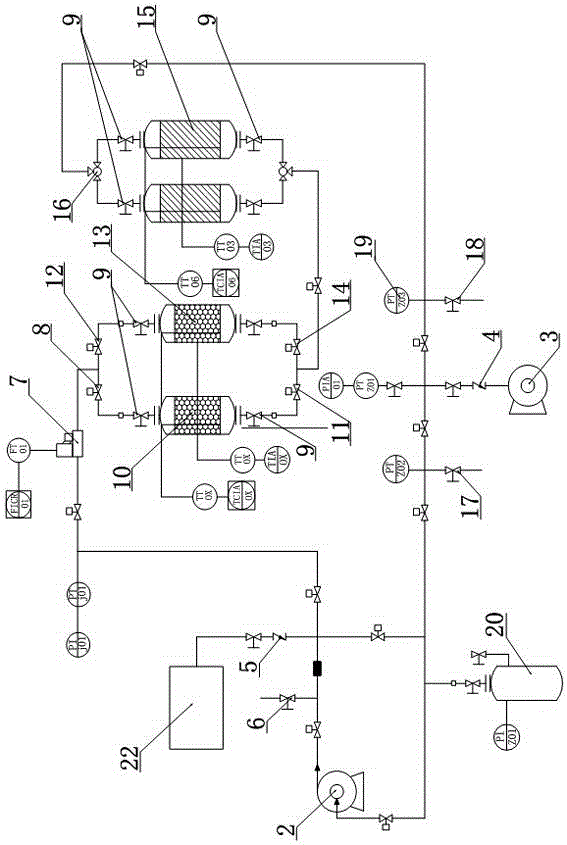

[0041] Such as figure 1 , 2As shown, the present invention is mainly used for transferring and purifying tritium when the tritium concentration exceeds the standard or tritium leakage occurs in the tritium system under an inert gas protective atmosphere or an oxygen-containing atmosphere. The present invention comprises a cabinet body 1, a gas circulation pump 2 and a gas storage tank 20, and movable wheels 21 are provided on the respective bottoms of the cabinet body 1, the gas circulation pump 2 and the gas storage tank 20, which can facilitate the rapid movement of the entire tritium removal purification device To various detritium occasions. The cabinet 1 is respectively provided with a vacuum pump 3, a flow controller 7, a catalytic suction device and an adsorption bed 15, wherein the gas circulation pump 2, the flow controller 7, the catalytic suction device and the adsorption bed 15 are connected in sequence and A circulation loop is formed, and an air supply valve 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com