A supporting structure of 750kv lead-out wires on the network side of UHV converter transformer

A converter transformer, lead wire technology, applied in the direction of transformer/inductor coil/winding/connection, preventing/reducing unwanted electrical/magnetic influence, etc., to reduce self-weight, reduce oil consumption, flexible connection and layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below with reference to the accompanying drawings, which is an explanation rather than a limitation of the present invention.

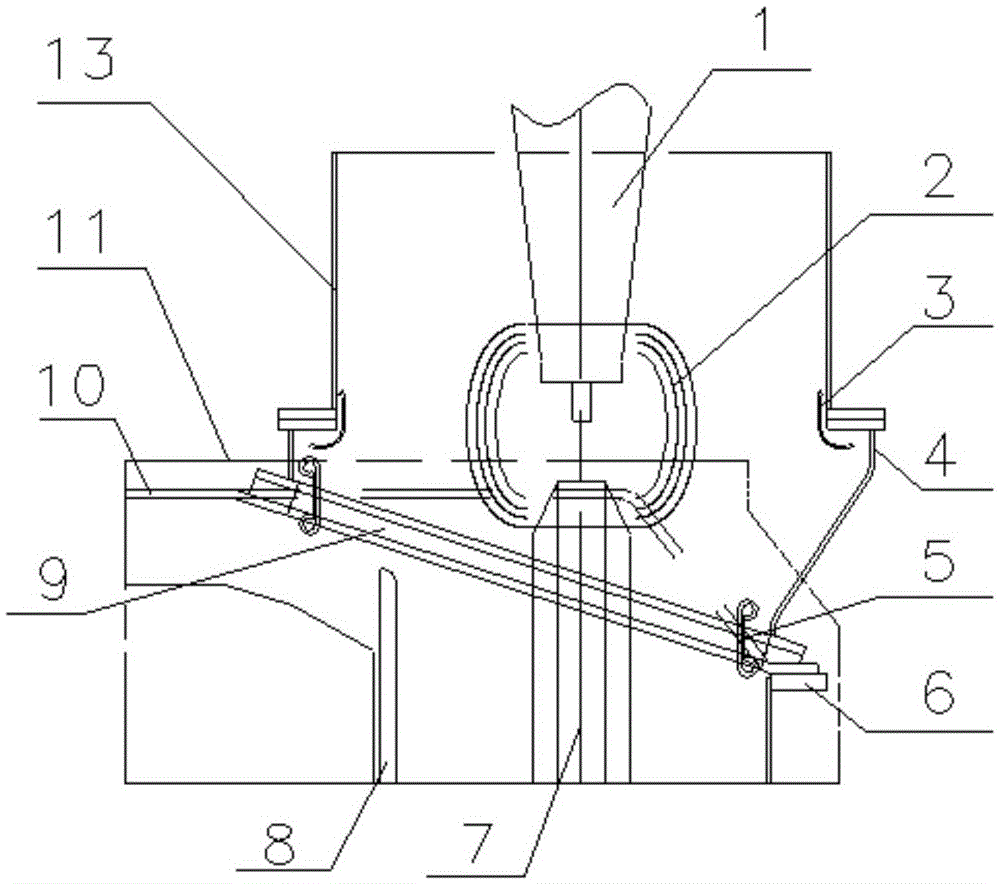

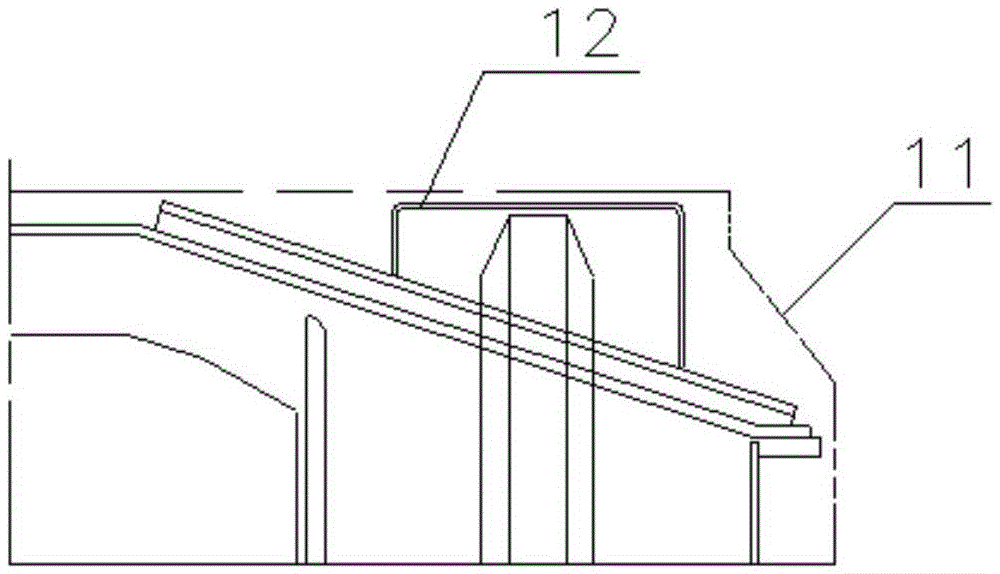

[0021] The present invention is a supporting structure of 750kV lead wire on the grid side of UHV converter transformer, such as figure 1 As shown, it includes a box cover 10 that is set above the edge 6 of the converter transformer box, an upper flange 9 of the box cover, and an inclined raised seat 4 and a straight raised seat 13 that are sequentially connected to the upper flange 9 of the box cover; The edge of 10 slopes downward to connect with the converter box edge 6. The upper flange 9 of the box cover is arranged on the inclined part of the box cover 10; the top end of the inclined riser 4 is horizontally connected to the straight riser 13, and the bottom end is inclined to the box. The cover flange 9 is connected; the diameter of the straight raised seat 13 is smaller than the top d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com