An esd protection device with igbt structure with high sustain voltage

A technology of ESD protection and high sustaining voltage, which is applied in the field of ESD protection devices and high-voltage ESD protection devices, can solve problems such as low sustaining voltage and insufficient anti-latch-up ability, achieve high sustaining voltage, enhance ESD robustness, and improve secondary Effect of Secondary Failure Current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

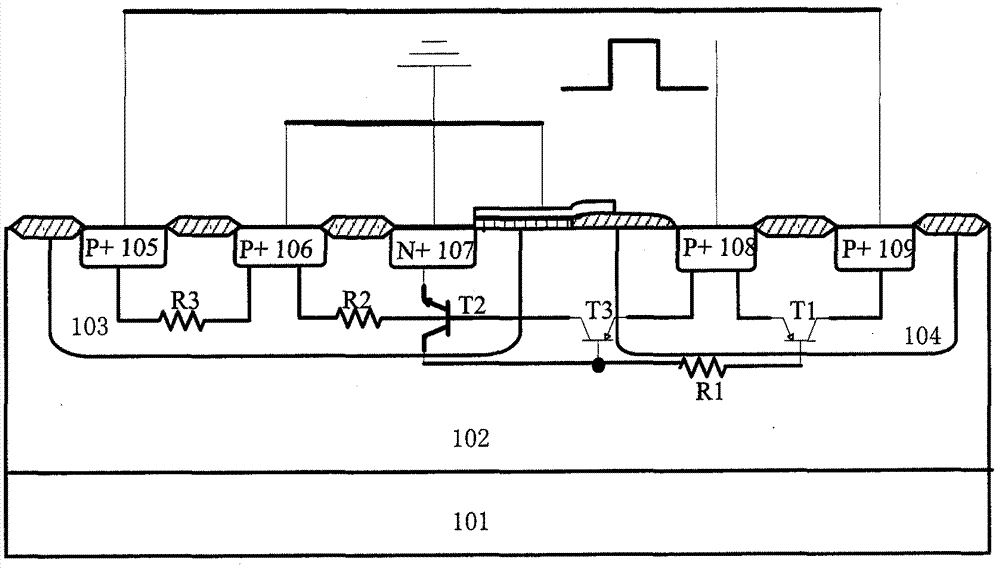

[0025] An example of the present invention designs an ESD protection device with an IGBT structure with a high sustain voltage, which not only makes full use of the strong current handling capability of the IGBT device, but also enhances the ESD robustness of the device. The increase of the P+ layout structure and the special metal connection can increase the maintenance voltage of the device. By adjusting the key layout size, the device can meet the high-voltage ESD protection in power integrated circuit products with different needs, and no latch-up effect will occur.

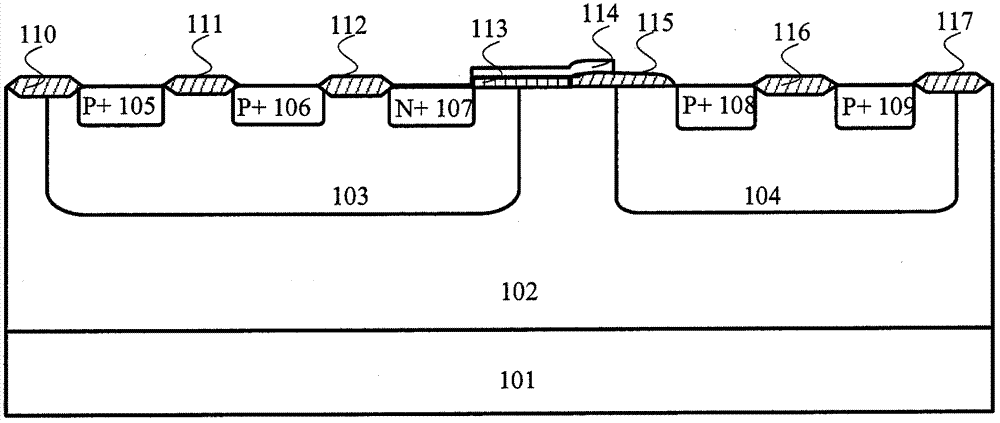

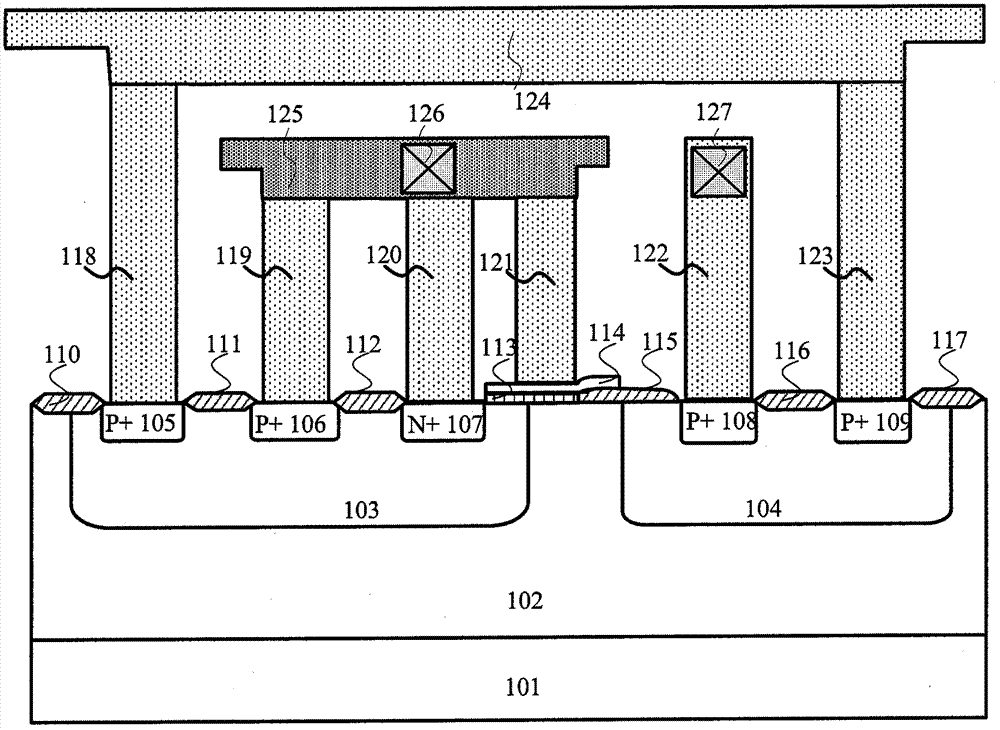

[0026] like figure 1 The cross-sectional view of the internal structure of the example device of the present invention is shown, specifically an ESD protection device with a high sustain voltage IGBT structure, with a PNPN structure and two ESD current discharge paths in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com