Explosive-proof synchronous belt chromium alloy motor

A synchronous belt and chrome alloy technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of increased internal friction, increased heat generation, increased linear speed of motor bearings, etc., and achieves extended service life and reliable operation. , the overall size of the effect of compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment;

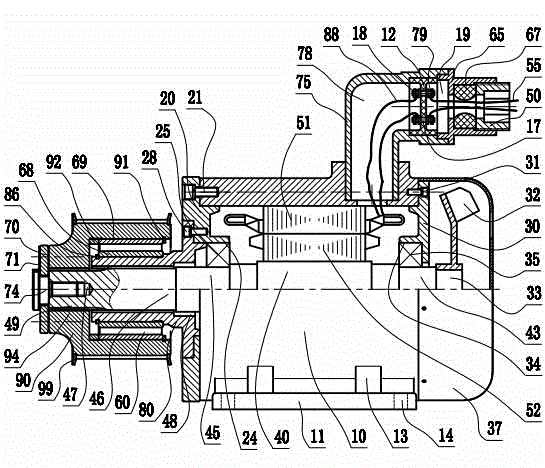

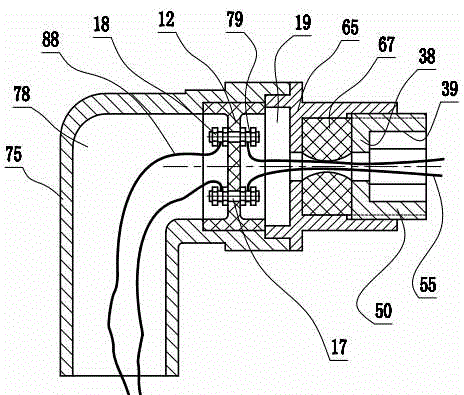

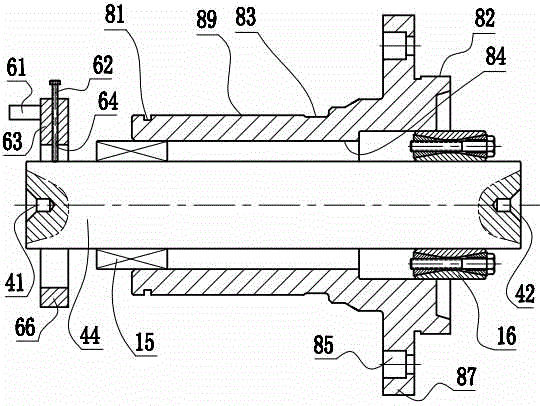

[0032]A flameproof synchronous belt chromium alloy motor, comprising a motor housing 10, a front end cover 20, a rear end cover 30, a motor main shaft 40, a lead screw plug 50, a stator 51, a rotor 52 and a synchronous pulley 90, and the stator 51 is fixed on the motor housing 10 on the inner hole, the rotor 52 is fixed at the maximum diameter of the motor main shaft 40 and corresponds to the position of the stator 51, the front screw 21 on the front end cover 20 is fixed on the front end of the motor casing 10, and the front cover bearing hole 24 on the front end cover 20 The outer circle of the front bearing 25 is fixed, and the front bearing section 45 of the motor main shaft 40 is fixed in the inner hole of the front bearing 25; the rear screw 31 is fixed on the rear end surface of the motor housing 10 on the rear end cover 30, and the rear cover cen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com