Potato peeler

A peeling machine, potato technology, applied in the peeling of vegetables or fruits, food science, application, etc., can solve the problems of operator's hand injury, high labor cost, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

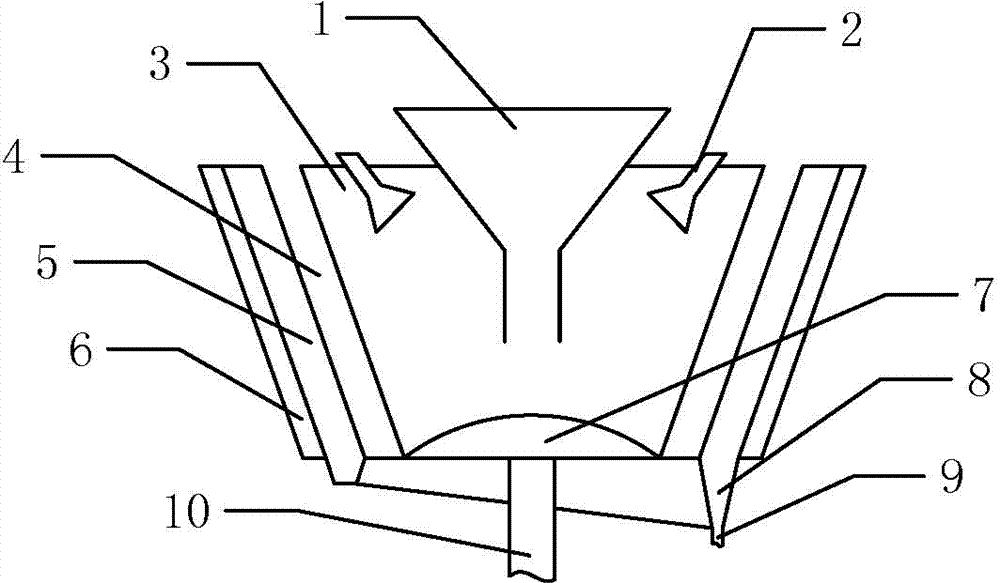

[0012] Among them: feeding hopper 1, nozzle 2, first drum 3, second drum 4, liquid collecting cylinder 5, cavity 6, protrusion 7, trapezoidal groove 8, liquid outlet pipe 9, rotating shaft 10.

[0013] Such as figure 1 As shown, the potato peeling machine of the present invention comprises a base plate, the lower end of the base plate is connected with a rotating shaft 10, the rotating shaft 10 is connected with a motor, the upper end of the base plate is provided with a first drum 3, and the base plate is located in the first drum 3. The protrusion 7, the protrusion 7 is spherical, and the surface of the protrusion 7 is covered with a rubber pad, the side wall of the first drum 3 is a corrugated surface, and a discharge port is opened on the side wall of the first drum 3 , there is a sealing door hinged at the discharge port, the sealing door is locked on the side wall of the first drum 3 through a lock, and the inner side of the sealing door is flush with the inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com