Contact-type applanation tonometer calibrating apparatus and method

A verification device and contact technology, applied in the direction of tonometer, etc., can solve the problems affecting the long-term stability and repeatability of the device, the sharpness of the knife edge, and the unstable balance, so as to achieve good long-term stability and repeatability, improve Accuracy level, effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

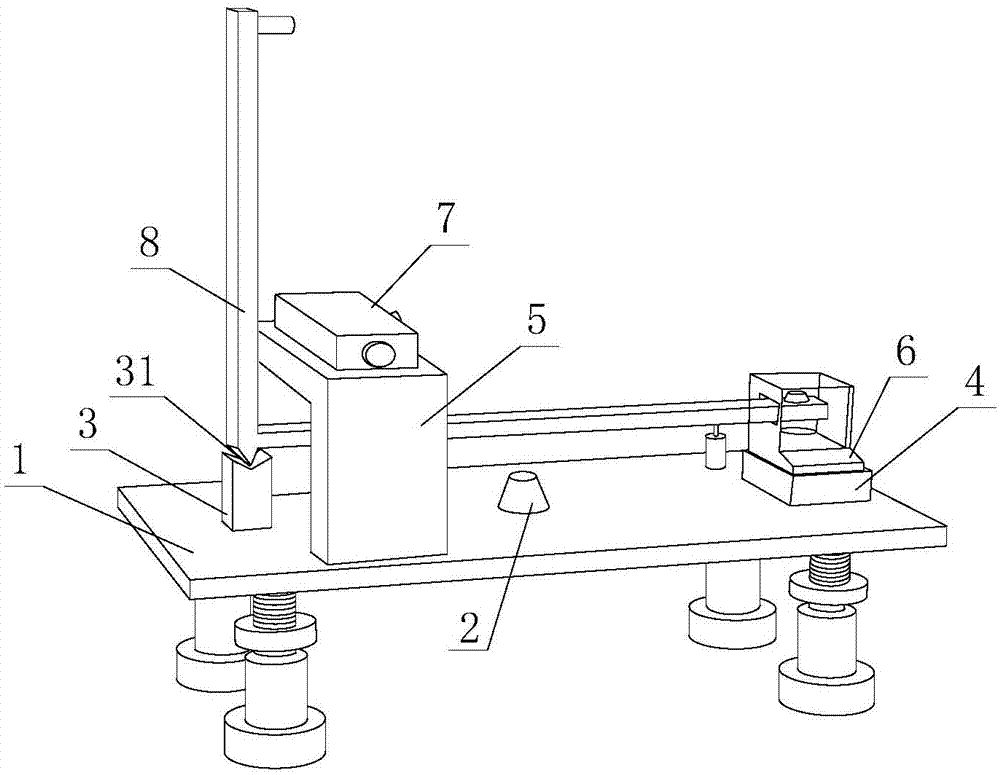

[0042] like figure 2 As shown, a verification device for a contact applanation tonometer includes a horizontal base 1 , an electronic balance 6 , a three-coordinate adjustment base 7 and an L-shaped balance bracket 8 .

[0043] The horizontal base 1 is rectangular and has four leveling feet. A first horizontal bubble 2 is provided on the front and rear center lines of the horizontal base 1, a vertically upward rectangular fixing column 3 is provided near its left short side, and a rectangular horizontal mounting platform 4 with a horizontal adjustment function is provided near its right short side , the front and rear symmetrical centerlines of the fixed column 3, the horizontal mounting platform 4 and the horizontal base 1 coincide. The top of the fixed column 3 is provided with a V-shaped notch 31 concaved from its left and right edges toward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com