Welding seam tracking device

A tracking device, lifting device technology, applied in welding equipment, arc welding equipment, manufacturing tools and other directions, can solve the problems of low work efficiency, low degree of automation, uneven welding seam, etc., to achieve stable welding quality, high degree of automation, Welding seam uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

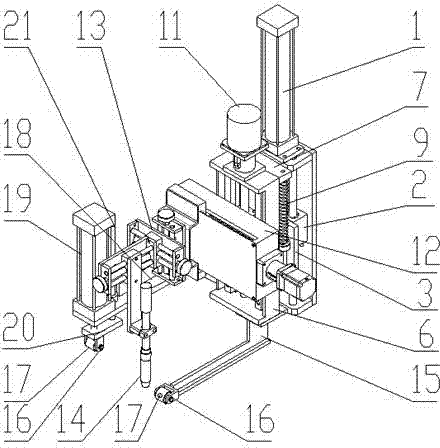

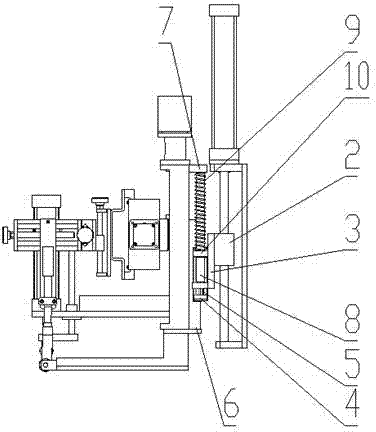

[0014] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a welding torch 14, an electric lifting device 11, a fast lifting device 1 and a tracking roller 17. A sliding seat 2 is installed on the bottom of the fast lifting device 1, and a fixed seat 7 is arranged on the electric lifting device 11, and a fixed seat is installed below the fixed seat. Guide shaft 8, balance spring 9 and retaining ring 10 are sleeved on the guide shaft 8, block 4 and slide block 5 are sleeved on the guide shaft 8 below the retaining ring 10, and are connected with slide seat 2 by connecting plate 3; The linear rectangular guide rail 6 and the slider 5 form a kinematic pair; the tracking roller 17 is provided with two optional ones, which are respectively set on the rolling shaft 16, and are connected to the electric lifting device 11 through the left connecting frame 18 and the right connecting frame 15. connection; the welding torch 14 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com