Vibration molding machineof film type hydraulic vibration exciter

A technology of hydraulic vibration exciter and vibration forming machine, applied in the field of vibration machinery, can solve problems such as low cost, and achieve the effects of low cost, no heat dissipation, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

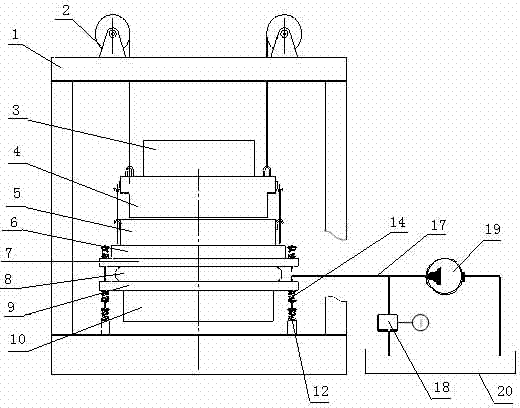

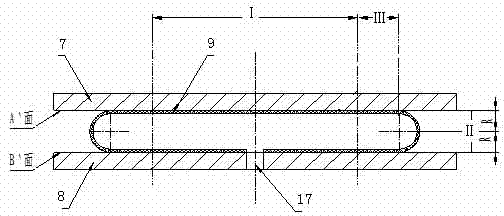

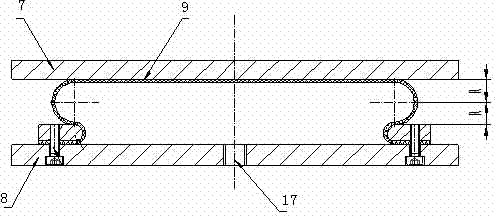

[0025] Thin-film hydraulic vibration exciter vibration molding machine, including frame 1, lifting device 2, upper counterweight 3, upper mold 4, lower mold 5, table top 6, lower counterweight 10, damping spring upper seat 13, damping spring 12 , Vibration-damping spring lower seat 21, it has canceled common mechanical exciter, and replaces it with film type hydraulic exciter. Such as figure 1 As shown, the lifting device 2 is installed on the top of the frame 1. From the upper counterweight 3 downwards are: upper mold 4, lower mold 5, table top 6, rigid plate one 7, film 8, rigid plate two 9, lower distribution Heavy 10, damping spring upper seat 13, damping spring 12, damping spring lower seat 21,

[0026] The membrane type hydraulic exciter consists of two parallel rigid plates, a membrane 8 made of flexible material that does not leak and is not easy to elongate, 14 sets of return springs, pipeline 17, DC pump 19, motor-driven switch valve 18 , liquid storage pool 20, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com